It’s never a good idea to let your inventory drop to zero. At the same time, you don’t want too much capital tied up in products that sit on eCommerce fulfillment warehouse shelves, gathering dust while you pay storage fees. Pursuing ways to improve inventory management is essential for your eCommerce success. When you improve inventory management, you improve your cash flow and reduce the chance of backorders and stockouts. Even if you think you’ve got an excellent system, a few tweaks could improve your inventory management.

If you could predict the timing and amount of your future sales with 100% accuracy, managing your inventory would be a breeze. The longer you’ve been in business, the more inventory data you have to help you improve inventory management. A good forecast will incorporate your business’s growth curve, market trends that could affect your bottom line, consumer confidence, and your sales and promotions calendar. However, the one thing you know to expect is the unexpected.

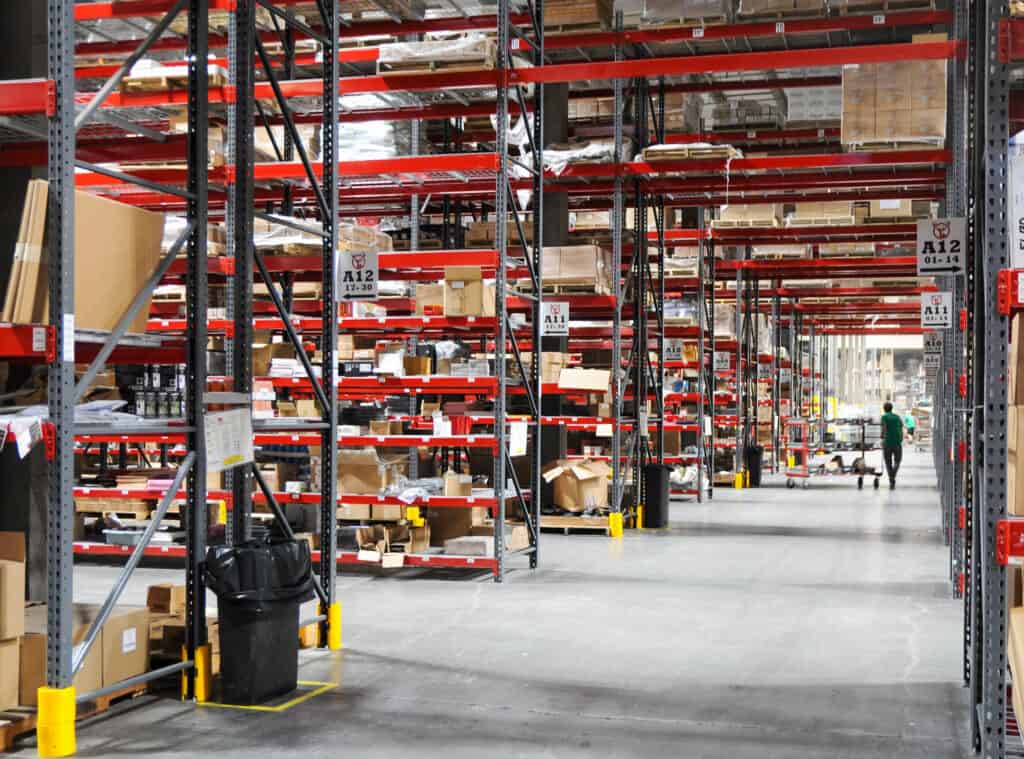

Finding the perfect balance between too little and too much inventory is a constant process of assessment and adjustment. Here are some tips to improve inventory management in your eCommerce business.

How to set eFulfillment inventory levels

The best path to inventory optimization is to follow the data. You can calculate optimal stock levels using inventory planning and demand forecasting. Here are some questions to answer as you begin the process of managing inventory more effectively:

- How long it takes for your manufacturer to fill an order

- The number of days your 3PL provider needs to process inbound shipments into inventory

- How quickly each SKU sells

Billing Address vs. Shipping Address

Understand your production and eFulfillment pipeline

To see how production affects your eCommerce fulfillment inventory, let’s look at an example. Emily designs garden sculptures and has them manufactured in a factory in Ohio. She sells statues of gnomes, birds, and other creatures through her online shopping site, Emily’s Garden. These pieces are shipped to homeowners from her fulfillment center in Tennessee.

When Emily reorders inventory, it takes her Ohio manufacturer six weeks to craft the statues and ship them to her fulfillment warehouse. If she runs out of her happy gnome statue, impatient gardeners will click over to her least favorite competitor, Gnarly Gnomes. She doesn’t want that to happen.

To keep from running out of product, Emily looks ahead. To do that, she needs to understand her business patterns.

Use data to plan stock levels

The first year Emily was in business, she made her best guesses about what would sell and when. She ended up with some items sitting around (the cement flamingos went over like, well, a cement flamingo) and ran out of others (her ravens practically flew off the shelves).

While Emily couldn’t predict the future of her new business, she didn’t go into it completely blind. She read articles on eCommerce buying habits and seasonal shopping for garden items. In her spare time, Emily pored through manufacturing statistics and other resources on the Small Business Administration website. She explored her competitors’ websites and used tools like Google Trends to see what designs were popular in the marketplace.

Look for patterns in your eCommerce sales

Emily did one brilliant thing from day one: she kept meticulous records of her sales. As the years went on, she created charts that showed her patterns that repeated from year to year. Spring was a busy time, as she had expected, but she also discovered that she sold a lot of statues in November and December. Her garden decorations made popular Christmas presents, especially in the Southwest. She saw that customers tended to buy larger sculptures in the spring and smaller ones in the fall.

Understanding these patterns allowed Emily to forecast inventory and set reorder levels. She might have a dozen grumpy gnomes in inventory in February, but she knew that she should still order five dozen more to be ready to beat Gnarly Gnomes to the buy button in April and May.

Remember the Big Picture When Calculating Total Cost to Deliver

How to set minimum stock levels

There is no perfect solution to the dilemma of balancing carrying costs against the need to have enough product on hand when an order comes in — how to have just enough stock but not too much. There is no way to achieve the perfect inventory level, but minimum stock levels are a great way to approach this balance. Set a minimum stock level for each item that allows you to order new stock before you run out. Base your minimum inventory on sales data combined with the time needed to acquire new stock.

If you sell about one polka dot dress per size per week, then you need to order when you have seven (or eight) on hand, so the new stock will arrive before you sell out.

Keep safety stock, in addition to minimum stock, to improve inventory management

Emily’s statues are expensive, as is the large amount of space it takes to store them. She doesn’t want to have any more of her business capital tied up in inventory than is necessary. She needed one more tool to make sure that she never ran out of stock.

That’s why Emily figured out how much safety stock she should keep, and you should do the same.

What is safety stock?

Emily can’t anticipate everything. Blizzards may add unexpected days to delivery times. A power outage can bring production at her manufacturer to a standstill.

That’s why Emily’s inventory calculations include safety stock. Safety stock is the perfect amount of extra inventory she needs to protect her eCommerce business from product shortfalls.

How do I figure out my safety stock level?

Emily uses a simple formula to calculate her safety stock. First, she multiplies the number of statues she sells on her busiest days by the greatest number of days it might take to get products from her manufacturer—for example, if there were a blizzard and a power outage. Then she multiplies her average daily sales figure by the average number of days it takes to get her products from the factory.

On a spring weekend, Emily often moves eight salamander statues a day. That is her top sales number. On average, she sells three salamanders per day.

On average, her manufacturer can fill an order for salamander statues in 42 days. When things go wrong, it can take up to 60 days to get salamanders onto the fulfillment warehouse shelves.

Emily’s formula looks like this:

(maximum daily sales x maximum production time in days) – (average daily sales x average production time in days) = salamander safety stock

For Emily’s salamander inventory, this translates to:

(8 x 60) – (3 x 42) = 354

Emily’s safety stock level is 354 salamander statues, which she keeps at her order fulfillment center, in addition to her regular inventory of this design. She will rarely if ever, miss a salamander sale because the item is out of stock.

Improve inventory management example: Understand your supply chain in the age of the Internet

Before a garden gnome arrives on the shelves of Emily’s fulfillment warehouse, several things must happen. Her supplier needs to order raw materials to make the gnome forms and paint to paint them. Then there’s the time to ship from the factory to her 3PL and get the gnomes logged into inventory.

This is Emily’s supply chain. When it’s working correctly, order management is a breeze. When something goes wrong, it can throw her inventory management into chaos.

Garden gnomes become an internet meme, causing a sudden surge in demand. A series of storms ground the freight airplane carrying your package, and your order is delayed. Problems at the factory delay production. Any number of glitches can throw a wrench in your otherwise orderly supply chain.

Some events are unavoidable, but understanding all the links in your supply chain can help you stay ahead of the extraordinary events that will sometimes come together to mess it up. At Red Stag, we think this is key to keeping your inventory fresh and moving smoothly.

That’s why Red Stag works with our customers to understand their supply chains. By analyzing past inventory data, we have helped small businesses develop a plan for order quantity and a reordering schedule to minimize supply chain hassles.

Carrying the smallest amount of inventory you need to turn over the most product is the best practice to reduce your carrying costs and increase your eCommerce success.

Get flexible with your SKUs

Even the best inventory management system can’t anticipate every spike in demand. For example, Emily sells a set of four cute toads as a family group.

As summer approaches, the sets are a big hit, and the fulfillment center runs out of stock. The individual toads are still in inventory, but they have different SKUs from the set. Orders keep pouring in for the toad family. What should Emily do?

At Red Stag Fulfillment, we can change the SKUs and convert individual items into cases, and vice versa. We find this is particularly helpful when our clients hit a crunch time, and there isn’t time to ship more stock in. And we don’t charge for SKU management, so you get flexible inventory management without add-on charges.

Don’t hang onto slow-moving or outdated inventory

When your inventory balloons out of control, it costs your business in several different ways. If you have $100,000 in inventory, and $70,000 of that is tied up in products that are just sitting on the shelf, that’s a terrible use of your capital. Your carried inventory doesn’t appreciate and can even lose value as style, or packaging changes make older products harder to sell.

That’s not the only carrying cost of inventory that sits dead on the shelves. There’s also a considerable opportunity cost component to cash tied up in inventory. The money you’ve spent on this zombie inventory could be more effectively spent on advertising or website upgrades that would boost your sales and truly improve the bottom line of your eCommerce business.

It’s easy to forget about this inventory since you aren’t at your order fulfillment warehouse every day. That’s another reason that Red Stag works with our customers on inventory management. We don’t make money when your stock sits on the shelf either; we want your inventory to turn over quickly, so we make money, and so do you. Keep tabs on what’s not moving, and put zombie inventory on sale. Clear the deadwood from your fulfillment center shelves, and you will be nimbler in this year versus last!

How to Identify Slow-Moving Inventory and What You Should Do with It

Improve inventory management by minimizing shrinkage

One of the most frustrating aspects of inventory management is managing the inventory that is no longer there. Shrinkage is a nice way to say damage, breakage, loss, and petty theft: all the reasons that a red polka dot dress size 10 isn’t on the shelf, even though your inventory says it should be.

Most fulfillment centers have an allowance for shrinkage. This means that your inventory management system is likely to have ghosts: items that appear in your inventory but aren’t on the warehouse shelf waiting to ship.

At Red Stag, we have a zero-shrinkage policy. Once we log your item into inventory, we guarantee it will be there. Our system tracks inventory so that not one thing is unaccounted for. In the unlikely event that one of our client’s products gets damaged or goes missing on our watch, we will reimburse them for the item’s wholesale price.

Stock that turns over continually is the lifeblood of a thriving eCommerce enterprise. Maintaining the optimal inventory level may not be the sexiest part of running your eCommerce business. Still, it is one area where an investment of time can bring you significant financial returns.

Bonus: Improve inventory management with software

Inventory management software will help you keep up with your stock without losing your head. There are several good programs available. If you run a very small business, a free program might work for you. If you have a bit more inventory to manage, you’ll probably want to pay for a more sophisticated inventory management app.

Here are some questions to help you pick the most effective inventory management software for you.

Can I take a test drive?

Most inventory software programs will give you a free trial. Take advantage of this — it could save you money, time, and headaches. Try out two or three programs to see which has the features that fit your needs most closely.

Is it easy to use?

Allow for a learning curve. The inventory management app that is best for your business, in the end, may not be the easiest one when you first open the dashboard. This is why it’s essential to give any new system that tracks inventory a thorough test run before adopting it. That said, if the software seems intuitive and easy to learn, give it bonus points.

Does it integrate with my point of sale (POS) systems?

Your inventory software needs to plug into your eCommerce platforms seamlessly. Find out how well a program integrates with your sales platform or platforms before you adopt it.

Does it provide real-time inventory data?

ECommerce is all about speed. If there’s a sudden surge in your sales, you need to know about it right away, so you can place an order for more.

Can it generate purchase orders?

It won’t make you toast in the morning and pour you a cup of coffee, but your inventory management software should be able to automate many of the tasks that take up your time right now. Let your inventory app generate purchase orders and help you determine your order quantity while generating profits to pump up your bottom line.

Let your eFulfillment warehouse help you improve inventory management

Emily initially overlooked one of her best sources for eFulfillment inventory assistance: her 3PL. She had to switch fulfillment warehouses twice in her first year because of inventory handling problems that cost her sales.

By the third time, Emily knew the right questions to ask, and she settled on a fulfillment warehouse that helps her maintain just the right inventory levels. Now she’s ready to ship something in the U.S.

Reduce out-of-inventory time

Because Emily’s garden statues take some time to create, she can’t afford to have her products sitting on pallets on the loading dock at the fulfillment warehouse for days. She looked for a 3PL that guaranteed to take her products off the truck and put them into their inventory system in two days or less.

Returns are another big issue for Emily. She doesn’t get too many statues back (she doesn’t like to brag, but her gnomes are ‘gnumber’ one), but, when she does get a return, she doesn’t want that piece to be out of inventory for any longer than is necessary. She chose a fulfillment center that processes returns quickly so that each gnome can find a new home.

Just say no to inventory shrinkage

One of Emily’s worst eCommerce fulfillment upsets was the week she spent trying to figure out why her fulfillment warehouse couldn’t send a statue of a toad on a toadstool to one of her very best repeat customers. Her inventory said that she had the piece in stock, and the fulfillment center also showed it in inventory. On the shelf, however, there was no toad.

Emily was the victim of inventory shrinkage. To calm her angry customer, she had to give him a deep discount on his next order. And she had to eat the loss on her missing product, plus her time spent on customer service.

Emily looked for a fulfillment center that guaranteed reimbursement for items lost or damaged in its warehouse. At Red Stag Fulfillment, we think this is one of the policies that separate us from the pack. We take your inventory just as seriously as you do. Missing toads upset us, too.

Your 3PL is your best resource to improve inventory management

Your fulfillment company is a great resource to help you create effective inventory management systems. At Red Stag Fulfillment, we work with our clients to help them figure out the optimal inventory to store in each warehouse. We’d love to talk with you about how we can help you improve your inventory management.