You’ve likely tried enough subscription boxes to know what kitting is for eCommerce, but do you know what makes kitting in the manufacturing process different?

This component kitting has the potential to help you cut expenses. It can optimize both the inventory and materials needed for your goods. Everyone is interested in saving money and improving operational effectiveness, so let’s look closer at what this means for you.

What’s the kitting in manufacturing process?

Kitting is the bundling of products, materials, or components to create a unified, single package. Often in the eCommerce space, we kit to turn many products into a single SKU to help companies sell more goods or increase order values. An eCommerce kit is often called a “product kit.”

Kitting in manufacturing can be the same, where a company kits after production is complete. They take the group of products they make and put them together for a single item. Typically, this is driven by a customer request or when a manufacturer sees patterns in goods being ordered together.

Manufacturers tend to call this “material kitting.”

Manufacturing companies also kit for internal processes using their own inventory. This generally happens as production lines become more intricate and larger or as machinery becomes more sophisticated. A manufacturer may take components of a finished product and kit them. Then, they deliver this bundle to another portion of a production line. Instead of working with many individual items, the worker or robotics can grab a material kit for their portion of product assembly.

Think of it like when you buy a murphy bed from Lori Wall Beds. All the screws and bolts you need come in a labeled package. That way, you can assemble the bed efficiently instead of spending time hunting around for necessary pieces during each step.

The importance of kitting process software

When companies use kitting for either purpose, it has an impact on their inventory management. Internally, they’re taking multiple items and combining them into something new. That turns multiple SKUs into a brand new one. Inventory management needs to update product counts of everything for each produced item.

Software makes this process significantly more manageable by automatically updating counts as units are produced. That’s true for material kitting in manufacturing and the kitting we provide for eCommerce companies. This removes the need for manual data entry, which can easily break the flow of your kitting or manufacturing process.

Where does kitting fit in the manufacturing process?

One unique element of material kitting in the manufacturing process is that it can happen at nearly any moment. Kitting can happen as soon as goods or raw materials are delivered to the manufacturing facility. Or, the manufacturer can combine these materials with something else they create further down the assembly line.

Manufacturers also use material kitting near the final assembly stages of complex products, delivering other components they created to these late points of use.

Point of use for kitting in manufacturing

Manufacturers can create and use material kits at any point in their process. The flexibility that manufacturers have allows them to support and test more options. They can change kitting quickly to ensure a reliable production flow or identify ways to reduce labor or parts used. Internal kits are often packaged for more immediate use. That allows for simpler boxing to minimize the cost of moving kits around a production floor.

Workers at the kit’s point of use know what should be in the bundle. That consistency keeps a production line efficient and makes it easier to manage quality or other concerns.

The manufacturing setup is a departure from eCommerce, where they create a product kit typically at the end of the packaging process. Here, we combine goods in a standard box or in custom packaging that promotes the benefits of this kit. Those sales messages could tout reduced costs, something gained for free, not running out as quickly, getting everything you need to enjoy a product, and more.

Sometimes, eCommerce kitting’s point of use is in the hands of a 3PL like Red Stag Fulfillment, moving it as close to the pick and pack process as possible. That allows businesses like yours to worry about the inbound logistics of fewer SKUs. You’d send us your inventory and then have kits created based on projections or actual order volumes. That can make your operations more dynamic while reducing the prep work you have for freight shipments.

What are the top benefits of kitting in manufacturing?

The benefits of kitting apply to both the manufacturer and its customers, covering both material and product kits. You may see these directly, such as the warehouse space needs, or indirectly, such as having a lower per-unit cost because the manufacturer is more efficient.

Lowers warehouse storage space needs

It’s easier to store a single kit near a workstation than to store many components separately. The worker can access a packaged kit and use it, then send the product down the chain. If the manufacturer is making kits in bulk, then kits will need to be stored on shelving. These shelves can be optimized to store as many kits as possible, and their uniformity makes this easier to achieve at a lower cost.

In this case, kits protect revenue in both storage and standardization.

Increases production space

A related but slightly different benefit is that a kit gives you more room for people and assembly equipment. The team can assemble items with less shop space needed because inventory isn’t stocked there. Delivering kits as part of internal services eliminates the need for large storage units, multiple drawers, and more. Gaining space makes it easier to design a production line for maximum efficiency, improve the business, and offer cost control around labor and equipment.

Speeds up manufacturing processes

Kitting is more than just a money consideration. For manufacturers, it’s one of the more common solutions for speeding up operations. Production lines can reduce the number of stops or points they need, for example, allowing the process to go faster by eliminating touchpoints. That reduces floor space used per product, allowing companies to produce more. Bundling components also makes it easier for workers to finish multi-step tasks more quickly.

Minimizes some shipping costs

Bundling helps manufacturers save on shipping costs in a few ways.

Internally, combining items will reduce the number of boxes moved between locations. That can often reduce the labor hours needed to ferry these items during the workday. These solutions also produce less wear on equipment because they make fewer stops and take fewer actions per item.

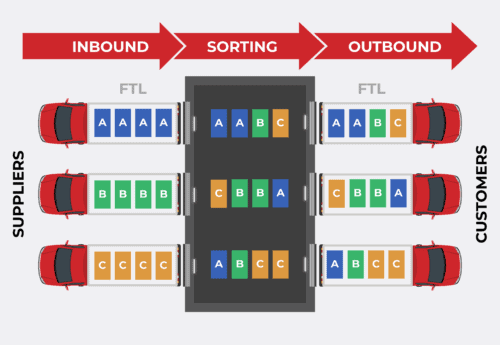

Externally, manufacturers can save on shipping by packing more products into an LTL or FTL shipment. They can then optimize kits and their packaging for freight shipments, moving more items at the same cost. That’s a common way to protect revenue.

Red Stag Fulfillment can help you with these kinds of calculations if needed. The first place to look is at our DIM weight calculator.

Simplifies inventory control

While software manages inventory control in most cases, kits still make this easier on the production floor. People can spot-check inventory or perform cycle counts more accurately because you’ve stored products uniformly.

The mix of software and predictable stacking helps a warehouse understand its inventory and avoids sales issues due to backorders and stockouts.

Offer more diverse products

One of the top benefits of kitting is that it helps manufacturers offer a broader range of products and components. They can sell you both an individual SKU or offer that and all the things related to it in a single, new SKU. In turn, you get to make that value proposition to your customers, offering them all the components they need to enjoy your best-selling products. It can even lead you to related categories based on the components and items available as well as your customer base.

And don’t forget that this kitting, done by your manufacturer or a 3PL partner like Red Stag Fulfillment, can help you reduce the cost to ship an order while it drives up the value of any sale.

Finding manufacturers with this flexibility may help you offer better products and services to your customers, especially if you run a dropshipping model.

Increases your satisfaction

When your manufacturer or 3PL kitting focuses on items that lead to sales, you’ll likely be happier with them. Happier customers, whether that’s you or the end-consumer, become repeat shoppers. Analyzing those habits with the latest sales software point out opportunities for you to partner with suppliers and offer a kitting subscription service to further drive sales.

Controlling labor and shipping costs on your sales means more money left in your pocket at the end of the day. We haven’t met a company that objects to profitable efficiency yet.

Flexible kitting in manufacturing

Kitting in manufacturing doesn’t look that different from what your business or Red Stag Fulfillment can do individually.

The advantage for producers is that they can treat parts of their shop floor or production line as “customers” to deliver kits to and cut costs. The logistics here is simpler and that benefit is essentially free because of the internal use. As they master these opportunities, they may offer you a number of similar solutions, for example. Then, your business can look for opportunities to expand sales with this or your own kitting.

Red Stag performs a similar role for many companies during a product’s final assembly. Our warehouse experts can help your business grow by combining the right goods into a branded box, so your clients get a great experience that highlights your business. Offering this at the warehouse just before we pick, pack, and ship an order gives you more flexibility to adapt kitting to current customer demand.

If you want to what that means for you and how kitting can highlight the quality of your business, it’s time to contact the Red Stag team.