Returns can be a challenge for any ecommerce business. The return is already a revenue loss, but then reverse logistics add to the challenge, threatening to eat away profit and constrain cash flow.

The transportation and labor costs to get the item back, restock, and hopefully resell it can have a domino effect. Poorly managed returns raise inventory costs, reduce gross margins, and scramble customer conversion metrics.

But streamlining customer returns is possible. Let’s look at how a 3PL return warehouse can minimize the impact of reverse logistics and help safeguard profitability for your online business.

The cost of returns processing

Returns have a major impact on financial performance. But online shoppers expect easy returns, so building reverse logistics cost savings into your supply chain is crucial.

National average return amounts

The National Retail Federation estimates the average retailer incurs $165 million in returns for every $1 billion in sales.

These figures are scaled. Most companies don’t sell that much, but it doesn’t mean the numbers are easier to swallow for smaller companies.

For a store with $1 million in revenue, it’s approximately $165,000 in returns. For a store with $250,000 in revenue, it’s just under $42,000.

Some product categories have higher risks, too. For example, clothing return rates were as high as 24% by the final quarter of 2023. At the low end, even hobby supplies, which tend to be niche and carefully chosen, have a return rate of approximately eight percent.

Return processing strategy

Overall, reverse logistics costs U.S. ecommerce companies approximately $100 billion annually. Most of that goes to transportation and labor. Research helps shape the challenge further, with Deloitte analysts finding there may be only so much optimization you can do.

Simply put, returns will always be a fact of ecommerce, but knowing there’s an economic floor—or minimum price you can expect to pay—may help you develop a benchmark and find a way to bring returns processing under optimal control.

Doing so can free you up to improve other parts of your business that may impact returns, like product-market fit or pricing strategies.

Working with a returns processing center can help you achieve this optimization and control. That’s because an experienced 3PL has mastered all the factors in cost-efficient returns fulfillment.

What is returns processing?

Returns processing refers to the activities and procedures involved in managing and handling product returns from customers. The process of deciding what to do with returned products is called disposition.

Customers may have various reasons for returns, like defects, mis-ships, and other mistakes. Sometimes, they just change their mind.

These reasons may impact how the return is handled and what it ultimately costs you, but all returns incur additional costs.

The way to mitigate these costs is by streamlining each of the steps in the returns process for the best disposition of each item.

You may also be able to help limit risks to customer satisfaction with a smooth process.

Fulfillment center returns steps

The returns process begins when the customer initiates the process, usually by going online to request shipping information for reverse logistics.

On their end, an optimal refund process is as simple as possible and includes free return shipping. They get a QR code or label they can print and then bring the item somewhere for shipping to your 3PL warehouse. In some cases, they may request pickup.

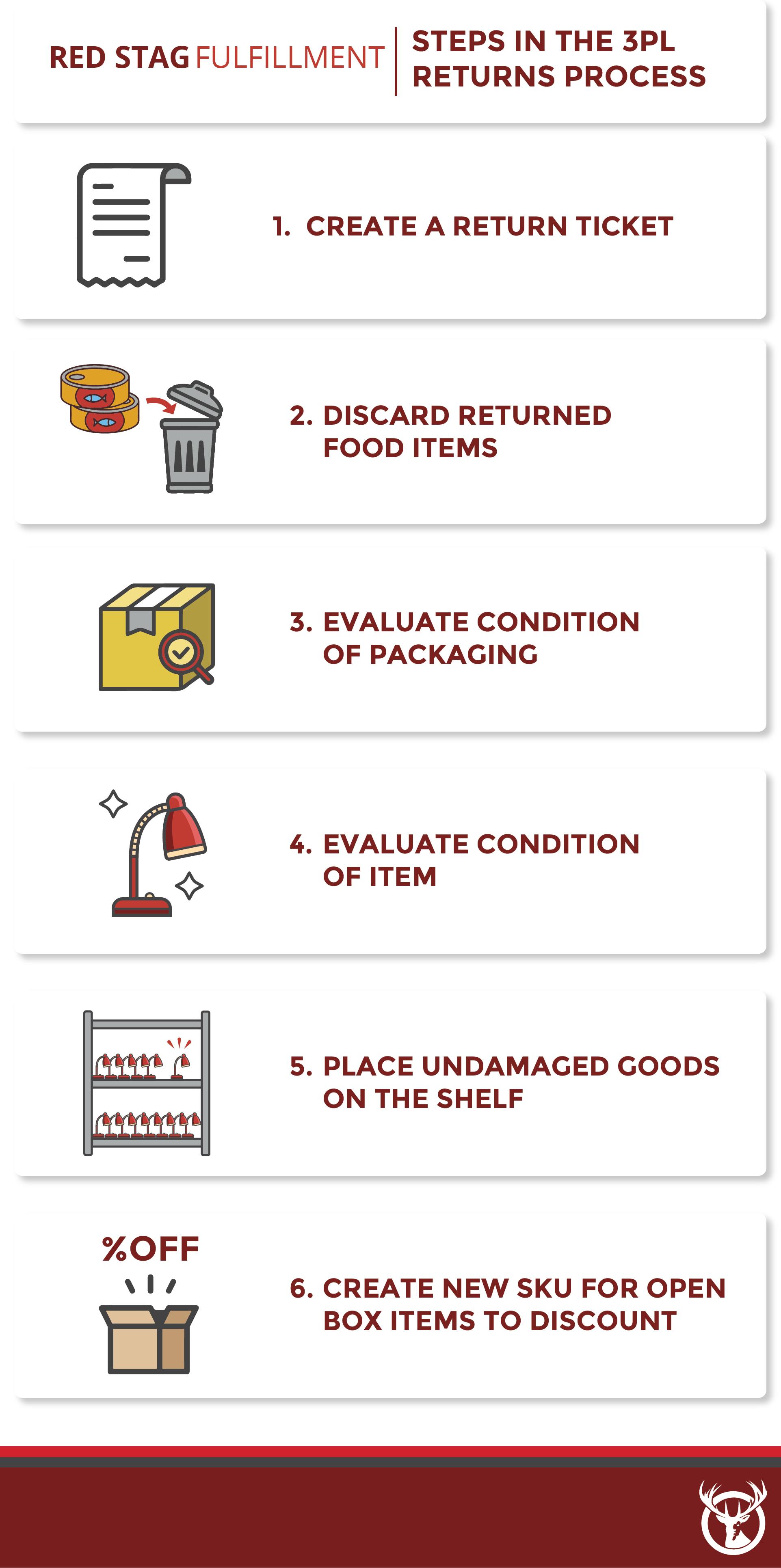

On the ecommerce side, the return process is much more involved. Here, we’ll break down the steps in processing returns as efficiently as possible.

Return merchandise authorizations

Return merchandise authorizations (RMA) facilitate the returns process for you, your customers, and your 3PL.

When customers start returns online, their return shipping information includes an RMA number, which they don’t necessarily need.

The number is an identifier for the item or items in the reverse logistics process. You can also use RMA numbers for reporting and analysis purposes, gaining insights into returned merchandise volumes, reasons, and trends.

RMA vs. RGA

Your returns processor may call return merchandise authorizations by another term, return goods authorization. They refer to the same thing.

You may also hear references to RMA or RGA warehouses. These warehouses may be dedicated to returns processing or handle returns for you with other fulfillment activities.

If you work with Red Stag Fulfillment, you’ll see RMA forms in your dedicated customer portal to help you easily manage returned merchandise.

Product inspections

In the 3PL returns processing center, warehouse staff conduct thorough product inspections to assess the condition of each returned item.

This critical step ensures only products meeting your quality standards go back into inventory. The exception is food products, which are discarded due to safety concerns.

For non-perishable items, the focus shifts to salvaging as much value as possible. Some new and unused items, like apparel, may often be restocked after careful inspection.

First, items are examined for signs of wear or damage. Once deemed suitable for resale, they may undergo a reconditioning process that includes steps like refolding clothes or repackaging components.

These efforts are slower than picking and packing in forward logistics but are crucial for making sure restocked products meet the same high standards as your new products.

Packaging

Packaging is important to many customers. In an era of online reviews and unboxing videos, where customers open packages on social media, damaged or compromised packaging may impact marketability.

If the product is still in good condition, your 3PL can rebox the item or help salvage packaging for you to resell it.

For ecommerce businesses that sell through marketplaces, you may have the option to mark specific products as used, but in good, very good, or like new condition. Some customers are happy to find these repackaged items because they can benefit from the discounted price.

Defects

Your 3PL can probably help you identify and handle defective items. Defects are products with flaws or malfunctions. Depending on the nature of the defect, your 3PL may take different actions.

Defects that come from the manufacturer may be returned to the manufacturer for reimbursement or credit on your next order.

Some products may be damaged beyond repair or use during transit. In these cases, your 3PL may help you submit damage claims to carriers as needed.

Some defects may occur in stages. Manufacturer quality processes may have missed something minor, which becomes more problematic further along the supply chain. For example, a part may be loose, but it passes factory checks only to come apart during transit.

With lots of unknowns to examine, a 3PL may be able to help you investigate, pulling records from across the supply chain process and connecting with other supply chain partners to discover what happened.

Restocking

Items that can be resold get restocked in the warehouse to help you capture new sales. This part of the returns process may require close attention to SKU management.

For example, if you need to restock items from a subscription box or a promotional bundle, your 3PL would need to reassign the SKUs that apply to each single item. And when items get repackaged as part of kitting services, the SKU would change again.

Another example may include discounted items. You may choose to create a separate SKU for discounted items to make sure your fulfillment center sends the correct item to customers. Selling a new item at a discounted price by mistake creates an additional loss of profit on the new item and ongoing carrying costs on the discounted one.

Accurate SKU management during restocking can provide data to support key insights for your supply chain, too.

Returns processing best practices

Following supply chain industry best practices for returns can help you achieve the optimal control mentioned earlier. Fast RMA handling and thorough inspections build a foundation for cost-efficient disposition of items.

Established 3PLs also have the infrastructure and resources to follow your instructions perfectly. This means you may be able to further optimize your returns process with strategic thinking and process-building.

Here are a few creative ways your 3PL or RMA warehouse can limit loss on ecommerce returns logistics:

- Save undamaged components until you can repackage them as a complete product.

- Repackage large or heavy items in plain boxes for reselling at a discount.

- Identify standards for refurbishment to increase how many returns can be resold.

- Bundle items with minor imperfections under new SKUs to drive customer satisfaction.

- Cross-sell during the returns process, suggesting similar items to replace returns.

- Integrate feedback requests into returns to improve product-market fit.

- Test dynamic pricing tactics and scale insights to optimize revenue generation.

By partnering with an experienced returns processor, you can fine tune your reverse logistics to limit loss and capture opportunity, even when dealing with such a troublesome industry challenge.

Work with our 3PL returns warehouse

Ready to streamline your reverse logistics and returns processing?

Red Stag Fulfillment is a strategic partner for ecommerce companies looking to optimize return processing for cost, speed, and efficiency.

One of the ways we drive value is with strategic fulfillment centers located in Knoxville and Salt Lake City. Shorter distances to your returns processing center help jump-start the process. When handling forward logistics, our locations let you reach 96% of U.S. homes within two days.

Red Stag also offers 100% accuracy and 0% shrinkage guarantees. These guarantees help shield you against the uncertainties of reverse logistics. If the mistake was ours, we’ll cover the costs and pay you an additional $50 for the inconvenience.

No other 3PL comes close to these guarantees. Reach out now to get started.