Understanding freight density can save your business thousands of dollars in shipping costs while preventing costly reclassification surprises. Whether you’re shipping steel plates or pillows, accurate freight density calculations determine your freight class and directly impact your bottom line.

TL;DR:

Key takeaways

Freight density directly impacts shipping costs through freight class determination

Accurate calculations prevent costly reclassifications and unexpected fees

Strategic packaging optimization can reduce freight class by 2-3 levels

What is freight density?

Freight density measures how much space your shipment occupies relative to its weight, expressed in pounds per cubic feet (PCF). This fundamental concept determines your freight classification and directly impacts your shipping costs.

NOTE: Density refers to the compactness of items in relation to their weight. For freight purposes, density describes the space occupied relative to weight, helping carriers determine appropriate pricing.

Think of it this way: a shipment of steel plates might weigh 2,000 pounds but occupy only 40 cubic feet, resulting in a high density of 50 PCF. In contrast, a shipment of pillows weighing the same 2,000 pounds might occupy 400 cubic feet, yielding a low freight density of just 5 PCF.

This difference matters significantly for carriers. Dense freight uses truck capacity efficiently, while low-density items like pillows consume valuable trailer space without maximizing weight capacity. Carriers adjust freight pricing accordingly through the freight class system.

The business impact is substantial. Higher density shipments typically qualify for lower freight classes, resulting in reduced shipping costs. Lower density freight faces higher freight classes and increased rates, making density optimization crucial for cost management.

For example, if you can increase your shipment density from 4 PCF to 6 PCF through better packaging, you might move from Class 250 to Class 175, potentially saving hundreds of dollars per shipment.

Link to our large item 3PL services for specialized handling of low-density, bulky shipments.

How to calculate freight density

Calculating freight density requires a simple formula, but accuracy is critical for avoiding reclassification fees and unexpected costs.

PRO TIP: Always measure and weigh your actual packaged shipment, including pallets and packing materials, to ensure accurate freight density calculations.

The freight density formula is: Density = weight (lbs) / total cubic feet, where cubic feet = (L x W x H in inches) / 1,728. This calculation gives you the pounds per cubic feet that carriers use to determine freight class.

Here’s the step-by-step process to calculate freight density:

Step 1: Measure your shipment dimensions Measure the length, width, and height of your entire shipment in inches, including all packaging materials and pallets.

Step 2: Calculate cubic feet Multiply length × width × height, then divide by 1,728 (the number of cubic inches in one cubic feet).

Step 3: Weigh your total shipment Use the total weight including all packaging materials, pallets, and products.

Step 4: Apply the density formula Divide your total weight by the cubic feet to get pounds per cubic feet.

Example calculation: A shipment measuring 48″ × 40″ × 60″ weighing 800 pounds:

Cubic feet: (48 × 40 × 60) ÷ 1,728 = 66.67 cubic feet

Freight density: 800 lbs ÷ 66.67 cubic feet = 12 PCF

Many shippers use a freight density calculator for quick verification, but understanding the manual calculation helps you optimize your packaging decisions.

The new 13-tier NMFC density scale ranges from Sub 1 (less than 1 lb per cubic feet = Class 400) to Sub 13 (50+ lb per cubic feet = Class 50)¹. Knowing where your density falls on this scale helps predict your freight class and shipping costs.

Link to our kitting services when discussing measuring multiple items or assembled products.

Freight class and density relationship

The relationship between freight density and freight class determines your shipping costs, making this connection crucial for logistics planning and budgeting.

Starting July 19, 2025, NMFC class codes for most general commodities are now based primarily on density rather than just commodity type². This change simplifies freight classification while making density calculations more important than ever.

ALERT: The density-based freight classification system means even small changes in packaging can significantly impact your freight class and costs.

Complete density-to-class conversion chart

The complete 13-tier density scale provides clear guidance for freight classification:

| Density Range (PCF) | Freight Class | Sub Classification |

|---|---|---|

| Less than 1 | 400 | Sub 1 |

| 1 to 2 | 300 | Sub 2 |

| 2 to 4 | 250 | Sub 3 |

| 4 to 6 | 175 | Sub 4 |

| 6 to 8 | 125 | Sub 5 |

| 8 to 10 | 100 | Sub 6 |

| 10 to 12 | 92.5 | Sub 7 |

| 12 to 15 | 85 | Sub 8 |

| 15 to 22.5 | 70 | Sub 9 |

| 22.5 to 30 | 65 | Sub 10 |

| 30 to 35 | 60 | Sub 11 |

| 35 to 50 | 55 | Sub 12 |

| 50+ | 50 | Sub 13 |

Additional freight classification factors

While density now dominates freight classification, carriers still consider other factors. Freight classification is determined by four factors: density, handling, stowability, and liability, with density now being prioritized³.

Handling refers to how difficult the freight is to load, unload, and transport. Items requiring special equipment or care may receive higher freight classifications regardless of density.

Stowability measures how well freight fits with other shipments. Oddly shaped items that waste trailer space may face freight classification penalties.

Liability accounts for the likelihood of damage or theft. High-value or fragile items often receive higher freight classes to reflect increased risk.

Understanding these factors helps explain why some freight doesn’t fit perfectly into density-based classifications and why working with experienced freight professionals remains valuable.

Link to our guide on 3PL costs when discussing how freight class affects overall shipping expenses.

Common calculation mistakes and solutions

Avoiding costly freight classification errors requires attention to detail and understanding of common pitfalls that trigger reclassification fees.

ALERT: Measurement errors are the most common cause of freight reclassification, often resulting in hundreds of dollars in additional fees and delayed shipments.

Measurement and weighing errors

Incomplete measurements: Many shippers measure only the product, forgetting to include pallet dimensions and packaging materials. A standard pallet adds 5-6 inches to height and weighs 30-50 pounds, significantly affecting density calculations.

Wrong measurement units: Mixing feet and inches in calculations creates dramatic errors. Always convert all measurements to inches before calculating cubic feet.

Estimated versus actual weights: Using product specifications instead of actual shipment weights leads to inaccurate freight density calculations. Always weigh the complete, packaged shipment.

Packaging oversights

Ignoring packing materials: Bubble wrap, foam, and other packing materials add both weight and volume. These materials can change your shipment density from dense to less dense, moving you into a higher freight class.

Irregular shapes: Not accounting for the full rectangular dimensions of irregularly shaped items understates cubic feet. Carriers charge based on the outer dimensions of your shipment’s rectangular footprint.

NOTE: Always measure your complete shipment as it will be loaded on the truck, including any dead space between items that cannot be utilized by other freight.

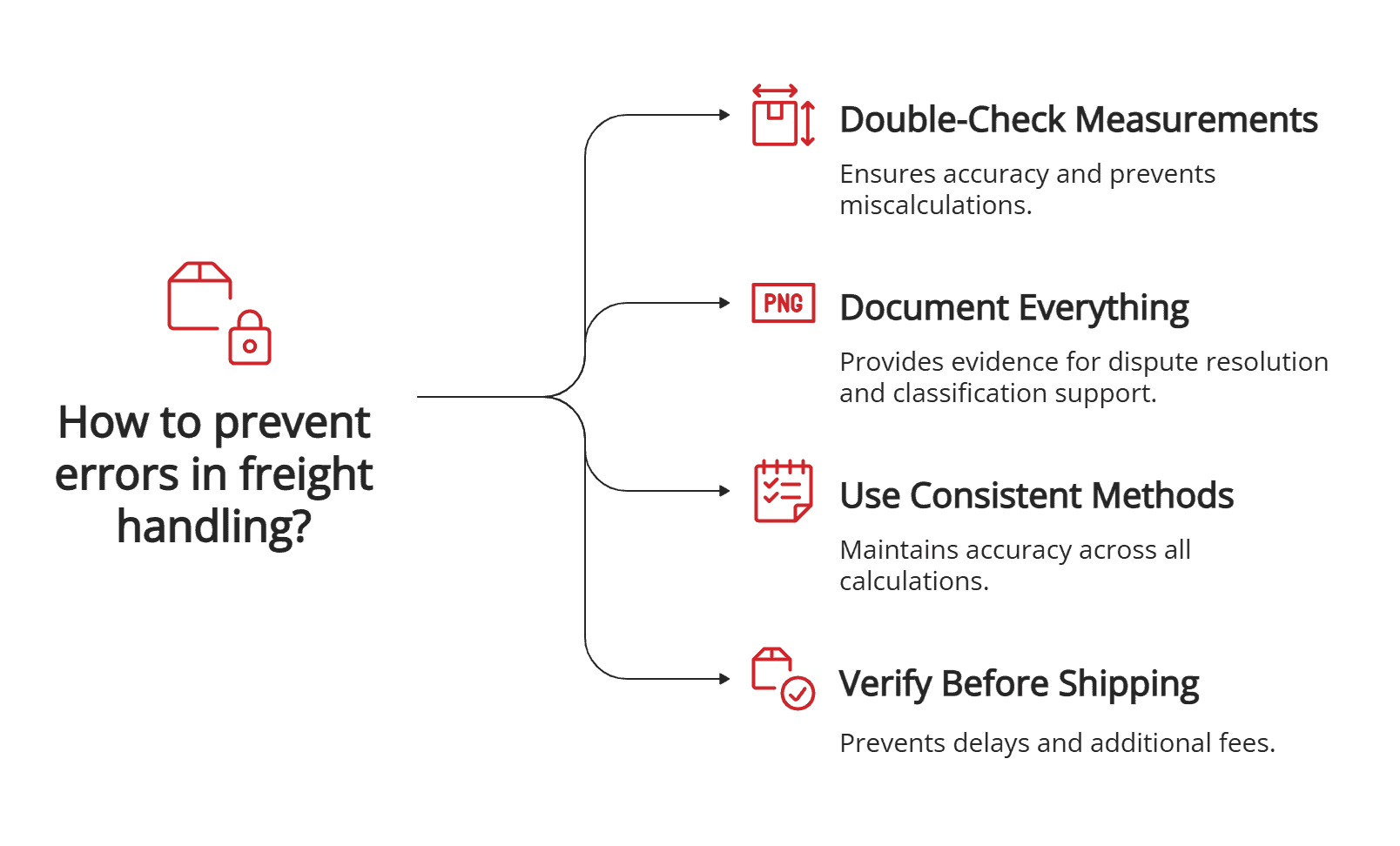

Prevention strategies

Double-check all measurements: Measure twice, calculate once. Have a second person verify critical measurements, especially for high-value freight.

Document everything: Keep photos and measurement records for your freight. This documentation helps resolve disputes and supports your freight classification decisions.

Use consistent methods: Establish standard measuring and weighing procedures for your team to ensure accuracy across all freight density calculations.

Verify before shipping: Calculate density and confirm freight class before scheduling pickup. This prevents delays and additional fees from reclassification.

Link to guidance on how to choose a 3PL when discussing getting expert help with complex classifications.

Freight density optimization strategies

Strategic density optimization can reduce your freight class by 2-3 levels, potentially saving thousands of dollars annually on shipping costs.

PRO TIP: Focus on increasing freight density rather than just reducing weight. A 10% increase in density often provides better cost savings than a 10% weight reduction.

Packaging efficiency techniques

Five key strategies can dramatically improve your freight density:

Reviewing packaging materials

Utilizing plastic film/stretch wrap for bundling

Using stackable configurations

Rethinking packaging design to use smaller boxes

Training employees on density metrics⁴

Right-sizing packaging: Eliminate excess space by using custom-sized boxes or adjustable packaging. Every inch of unused space reduces your freight density and increases your freight class.

Compression techniques: Use shrink wrap, banding, or compression straps to minimize the space occupied by compressible items like textiles, foam, or packaged goods.

Advanced optimization methods

Custom packaging solutions: Work with packaging engineers to design boxes and containers that maximize density for your specific products. Initial investment in custom packaging often pays back quickly through reduced freight costs.

Multi-product bundling: Combine complementary products in single shipments to increase overall density. Dense items can offset less dense items in the same shipment.

Strategic palletization: Use standard pallet sizes efficiently and consider double-stacking when products allow. Higher stacks increase freight density by spreading pallet weight across more product volume.

OTHER: Quick tip: Calculate the density improvement from each packaging change before implementation to prioritize the most impactful modifications.

Link to working with a third-party logistics company when discussing professional optimization services.

When to use freight density calculators

Freight density calculator tools streamline calculations, but knowing when and how to use them effectively ensures accuracy and saves time.

NOTE: While freight density calculator tools provide quick estimates, always verify critical calculations manually for high-value or frequently shipped freight.

Benefits of digital tools

A freight density calculator excels at rapid calculations when you’re evaluating packaging options or quoting shipping costs to customers. They eliminate math errors and provide instant results for density comparisons.

Speed advantages: Calculate multiple packaging scenarios in minutes rather than hours. This speed helps when evaluating different box sizes or packing configurations.

Documentation capabilities: Many freight density calculator tools save calculation history, creating records for freight class justification and audit purposes.

Manual versus automated calculations

When to calculate manually: Verify automated results for unusually shaped freight, high-value shipments, or when disputing carrier reclassifications. Manual calculations help you understand the relationship between dimensions, weight, and density.

Accuracy considerations: Both manual and automated methods can produce errors. The key is using consistent measurement practices regardless of calculation method.

PROS/CONS: Carrier calculators provide exact accuracy for that specific carrier but may not reflect industry standards; third-party tools offer broader perspective but may not match specific carrier methods exactly.

Link to understanding ecommerce fulfillment when discussing integration with ecommerce shipping workflows.

Conclusion

Mastering freight density calculations transforms your shipping operations from a cost center into a competitive advantage. By understanding the density formula, avoiding common mistakes, and implementing strategic optimization techniques, you can significantly reduce freight costs while ensuring accurate classifications.

Citations

Old Dominion Freight Line. “Maximizing Density for LTL Shipping Efficiency.” ODFL Blog, 8 Apr. 2025. https://www.odfl.com/us/en/resources/freight-knowledge/odfl-blog/maximizing-density-LTL-shipping-efficiency.html.

ArcBest. “Freight Class and NMFC Code Basics.” ArcBest Blog, 22 July 2025. https://arcb.com/blog/freight-class-and-nmfc-code-basics.

SC Solutions Inc. “Freight Class and NMFC Codes: How to Calculate Freight Class by Density for LTL Shipments in 2025.” SC Solutions, 7 July 2025. https://scsolutionsinc.com/freight-class-and-nmfc-codes-how-to-calculate-freight-class-by-density-for-ltl-shipments-in-2025/.

National Motor Freight Traffic Association. “NMFC Codes & Freight Classification.” NMFTA, 5 Aug. 2025. https://nmfta.org/nmfc/.