Shipping an engine across the country for a fraction of what most people expect? It’s possible when you know the right approach.

Most people assume engine shipping costs a fortune — and it can if you make common mistakes like choosing expedited carriers or skipping proper preparation. But here’s what the shipping companies don’t advertise: with the right method and preparation, you can ship most engines safely for a reasonable cost using LTL freight.

Whether you’re restoring a classic Mustang, running an auto shop, or need a replacement motor delivered, this guide eliminates the guesswork from engine transport. You’ll discover the exact steps professionals use to ship engines safely while avoiding the costly mistakes that can multiply your shipping bill.

What you’ll learn

Best shipping methods and cost ranges for different engine types

Step-by-step preparation and packaging requirements

How to select the right carrier and negotiate better rates

Documentation and legal compliance essentials

When to schedule pickup and delivery coordination

TL;DR:

Key takeaways

LTL freight typically offers the best value for most engine shipments

Proper fluid drainage and preparation prevents costly damage

The right packaging choice can save hundreds on freight class fees

Best methods for shipping an engine

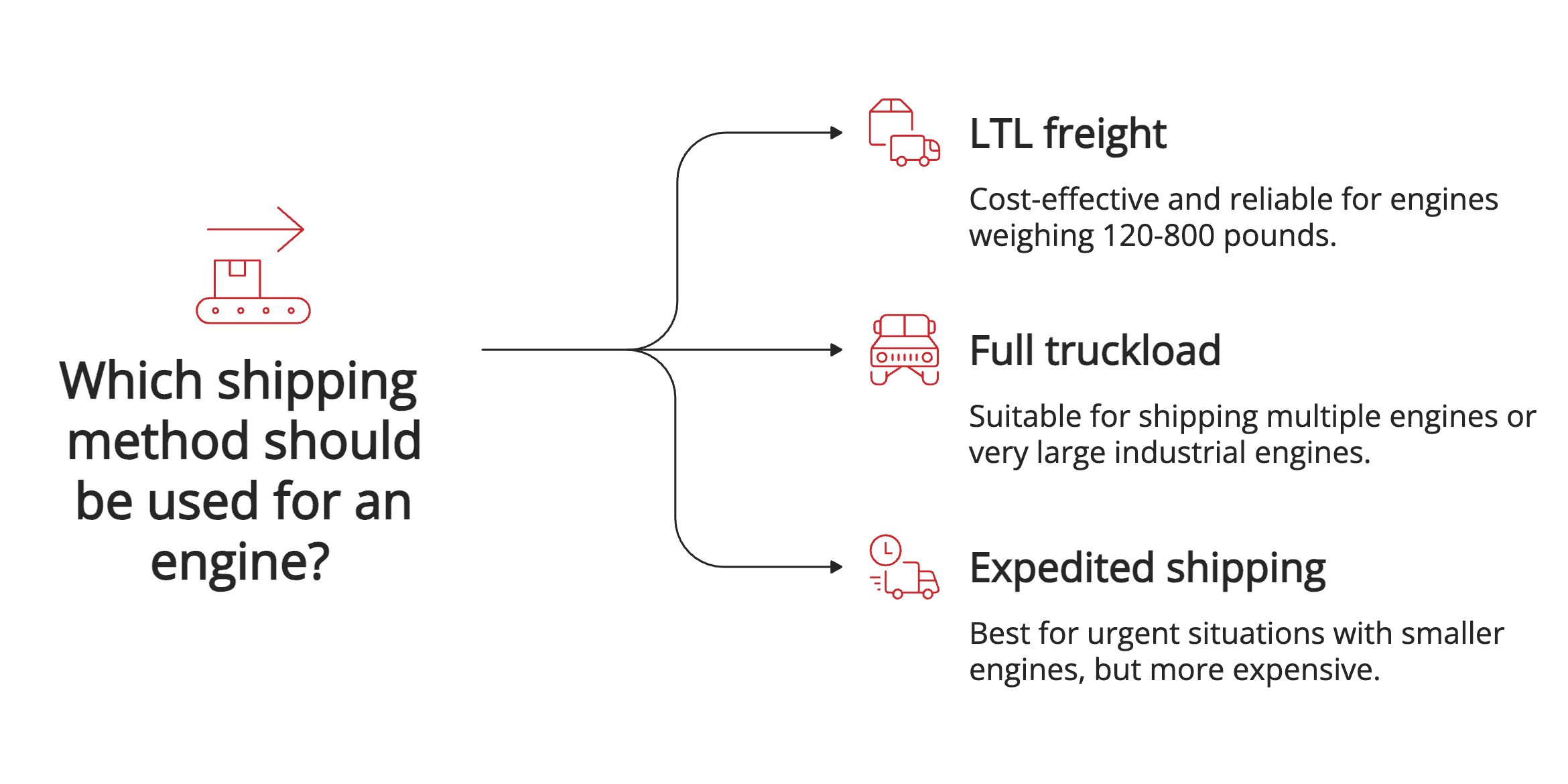

When it comes to shipping an engine, you have three main transportation options, each with distinct cost implications and service levels.

PRO TIP: LTL freight offers the best balance of cost and reliability for most engine shipments, especially those weighing between 120-800 pounds.

LTL freight shipping (recommended)

Less-than-truckload (LTL) freight shipping is the most cost-effective method for engines weighing 120-800 pounds. LTL quotes start as low as $100+ and generally fall between $120-$380, making it the go-to choice for most engine shipments. This method allows you to share truck space with other freight, significantly reducing costs compared to dedicating an entire truck to your single engine.

LTL freight provides excellent value because carriers specialize in handling heavy, dense items like engines. The freight networks are well-established, offering reliable transit times and professional handling equipment designed for automotive components. For businesses that need specialized fulfillment services for large items, LTL freight integrates seamlessly with warehouse operations.

Full truckload vs LTL comparison

Full truckload (FTL) shipping only makes financial sense when you’re shipping multiple engines or extremely large industrial engines. A single standard engine rarely justifies the cost of dedicating an entire truck. However, if you’re relocating a shop’s entire engine inventory or handling multiple motors, FTL provides faster transit times and reduces handling touchpoints.

When to use alternative methods

Expedited shipping through carriers like FedEx or UPS becomes necessary only for urgent situations, but expect to pay significantly more than standard freight rates. These services work best for smaller engines where speed trumps cost considerations.

Engine shipping preparation guide

Proper preparation is crucial for safe engine transport and regulatory compliance. Skipping these steps can result in rejected shipments, fines, or serious safety hazards during transit.

ALERT: Fuel tanks must be drained and securely closed, except up to 500 mL (17 ounces) of residual fuel may remain according to DOT regulations.

Draining all fluids (step-by-step)

Federal regulations require engines to be drained of all fluids, capped, and cleaned externally before shipment. This isn’t just a safety requirement—it’s legally mandated for transportation.

Start by draining all engine oil using the standard drain plug method. Allow the engine to sit for several hours to ensure complete drainage. Next, remove all coolant from the radiator, engine block, and hoses. Finally, drain any remaining fuel from carburetors, fuel lines, and fuel rails. Even small amounts of residual fluids can create hazardous conditions during transport.

Cleaning and inspection

After fluid drainage, thoroughly clean the engine exterior to remove oil, grease, and debris. This prevents contamination during your shipment and makes inspection easier. Use degreasing agents and pressure washing if necessary, but ensure the engine is completely dry before packaging.

Document the engine’s condition with detailed photographs from multiple angles. This creates a record for insurance purposes and helps identify any damage that occurs during transport.

Removing loose parts

Detach any components that could break off during shipping, including air filters, belts, hoses, and external accessories. Package these separately and clearly label them as belonging to the engine shipment. This prevents damage to both the engine and loose components.

Packaging your engine for safe transport

The packaging decision between crating and palletizing dramatically affects both protection level and shipping costs, making it one of the most important choices when you ship an engine.

NOTE: Crated engines qualify for freight class 70, which typically results in lower shipping rates than palletized engines classified as class 85.

Crating vs palletizing decision guide

Crating provides superior protection and often lower freight costs, while palletizing offers convenience and speed. The choice depends on your engine’s value, shipping distance, and budget constraints.

A crate works best for valuable, rebuilt, or vintage engines where damage prevention justifies the additional cost. The enclosed wooden structure protects against impacts, weather, and handling damage. A pallet suits standard replacement engines where speed and cost efficiency take priority over maximum protection.

DIY crating instructions

Building a proper engine crate requires marine-grade plywood, 2×4 lumber for framing, and heavy-duty hardware. Start with a base slightly larger than your engine’s footprint, using ¾-inch plywood reinforced with 2×4 runners.

Construct walls using ½-inch plywood panels screwed into a 2×4 frame. Leave adequate space around the engine for cushioning materials. Install engine mounting points using heavy-duty eye bolts or chain attachments. The crate must be sturdy enough to handle forklift operations and multiple handling events.

For professional results without the DIY effort, consider professional packaging and assembly services that specialize in heavy item preparation.

Pallet shipping best practices

When you pallet an engine, use heavy-duty pallets rated for at least 2,500 pounds. According to freight classification guidelines, a 4-cycle engine (palletized, strapped, shrink-wrapped) has NMFC 1207790.01, Class 85.

Secure the engine using heavy-duty ratchet straps rated for twice the engine’s weight. Cross-strap the engine in multiple directions to prevent shifting. Apply industrial shrink wrap over the entire pallet assembly to protect against weather and debris.

Securing and cushioning techniques

Use dense foam padding or cardboard to fill void spaces and prevent movement within the packaging. The engine should not shift when the package is tilted or moved. Double-wrap any exposed surfaces with protective materials to prevent scratches and corrosion during transit.

Understanding engine shipping costs

Engine shipping costs vary significantly based on weight, distance, packaging method, and carrier selection. Understanding these variables helps you budget accurately and choose the most cost-effective approach to ship an engine.

Typical cost ranges

Real-world shipping costs demonstrate the impact of weight and distance on engine transport. A 1000-pound engine costs $350 from California to Iowa, while a 250-pound engine costs $200 from Maryland to Washington. These examples show how both weight and distance affect your total shipping investment.

The key to managing costs is understanding that freight class 70 covers automobile engines with a density range of 15 to 22.5 pounds per cubic foot. Proper packaging can help you achieve this favorable classification.

Freight class explanation

Freight classification directly impacts your shipping costs. Engines typically fall into freight class 70 or 85, depending on packaging and density. The lower the class number, the lower your shipping rate.

Dense, properly packaged engines achieve better freight classifications, resulting in significant cost savings. A crated engine often qualifies for class 70, while a palletized engine might be classified as class 85, costing 20-30% more to ship an engine.

Weight, distance, and packaging factors

| Engine Type | Local Shipping Cost | Cross-Country Cost |

|---|---|---|

| Small Car Engine | $150-300 | $400-600 |

| Standard V6/V8 | $200-400 | $500-800 |

These costs assume proper preparation and standard LTL freight methods. Expedited services, special handling, or peak season shipping can increase costs by 50-100%.

Getting accurate quotes

Request quotes from multiple carriers to ensure competitive pricing. Provide accurate weight, dimensions, and destination information to avoid surprises. Consider using freight brokers who can compare rates across multiple carriers, but verify their reputation and service record before committing.

For businesses regularly shipping engines or other heavy items, explore understanding logistics pricing structures to optimize your shipping strategy.

Choosing the right shipping carrier

Selecting the right carrier affects both cost and service quality. Different carriers excel in various aspects of engine shipping, from geographic coverage to handling expertise.

Key comparison factors

Evaluate carriers based on their LTL network coverage, insurance options, and tracking capabilities. Some carriers specialize in automotive freight and offer better handling procedures for engines. Others provide broader geographic coverage but may lack specialized equipment.

Consider the carrier’s damage claim history and resolution process. Engine shipping involves significant value, making reliable damage protection and quick claim resolution essential for your peace of mind.

Major carrier options

Top LTL freight carriers include FedEx Freight, Old Dominion, XPO, Estes, R+L Carriers, SAIA, ABF Freight/ArcBest, and TForce Freight. Each offers different advantages in terms of coverage area, pricing, and service levels.

TForce Freight has pioneered density-based pricing models delivering significant cost savings for dense freight like engines. FedEx Freight provides extensive tracking capabilities and integration with their parcel network for comprehensive logistics solutions.

When evaluating carriers, consider selecting the right logistics partner principles that apply to both shipping and fulfillment decisions.

Insurance and tracking considerations

Standard freight coverage typically provides limited protection per pound, which rarely covers an engine’s full value. Purchase additional insurance or declared value coverage for engines worth more than basic coverage limits.

Modern tracking systems allow real-time monitoring of your engine shipment. Choose carriers that provide proactive updates and have customer service representatives available to address concerns during transit. Many carriers now offer pickup scheduling tools to coordinate the collection of your packaged engine.

Engine shipping by type

Different engine types require specific handling approaches and packaging considerations. Understanding these differences helps ensure appropriate preparation and realistic cost expectations when you ship an engine.

Car/truck engines

Standard automotive engines represent the most common shipping scenario. These engines benefit from standardized handling procedures and competitive pricing due to shipping volume.

Automobile or aircraft engine classifications receive favorable freight treatment due to their common shipping requirements and standardized packaging approaches.

Motorcycle engines

Motorcycle engines in crates are classified as NMFC 120790.02, Class 70, often resulting in lower shipping costs than larger engines. Their compact size and relatively light weight make them ideal candidates for both crate and standard pallet packaging approaches.

The type of engine affects both packaging requirements and freight classification, with smaller engines often achieving better shipping rates per pound.

Small engines (lawn equipment)

4-cycle engines from lawn mowers, generators, and similar equipment typically ship very cost-effectively due to their size and weight. These engines often qualify for standard parcel shipping when properly prepared and packaged.

Heavy industrial engines

Large industrial engines require special handling procedures and often need custom packaging solutions. These motors may require dedicated transportation or special equipment for loading and unloading, significantly increasing shipping costs when you ship an engine of this size.

Documentation and legal requirements

Proper documentation ensures smooth shipping and regulatory compliance. Missing or incorrect paperwork can result in delays, fines, or refused shipments.

READ MORE: For detailed shipping compliance requirements, see our guide to international shipping regulations.

Bill of lading essentials

The bill of lading serves as your shipping contract and must accurately describe your engine, including weight, dimensions, and special handling requirements. Include the proper National Motor Freight Classification number to ensure correct pricing and handling.

NMFC codes and classification

Use the correct national motor freight classification number for your specific engine type and packaging method. This classification directly affects your shipping cost and ensures proper handling by the carrier.

Insurance documentation

Document your engine’s value and condition before shipment. Take photographs and maintain receipts for insurance purposes. Consider additional coverage beyond standard freight protection for valuable or rebuilt engines.

Frequently asked questions

What’s the cheapest way to ship an engine?

The cheapest way to ship an engine is typically LTL freight. Proper crate packaging can reduce freight class and lower overall costs compared to palletized shipments.

Do I need to drain fluids before shipping?

Yes, you must drain the oil, coolant, and fuel from engines before shipping. Federal regulations require this for safety and environmental protection during transport.

How do I prevent damage during shipping?

Prevent damage by proper fluid drainage, secure packaging (a crate is best), adequate cushioning, and choosing carriers experienced with automotive freight. Document the condition before shipping and purchase appropriate insurance coverage.

Citations

- FreightRun. “Engine Shipping – Motor Freight Shipping Rates.” FreightRun, 2025. https://www.freightrun.com/services/oversize-load/engine-shipping

- Fulfyld. “How Much Does It Cost to Ship an Engine.” Fulfyld Blog, 30 May 2025. https://www.fulfyld.com/blog/how-much-does-it-cost-to-ship-an-engine/

- Cornell Law School. “49 CFR § 173.220 – Internal combustion engines, vehicles.” Legal Information Institute, 21 Dec 2020. https://www.law.cornell.edu/cfr/text/49/173.220

- TSI Shipping. “How Do I Ship Engines & Transmissions?” TSI Resource Center, 2025. https://www.tsishipping.com/resource-center/how-do-i-ship-engines-transmissions

- PHMSA. “Interpretation # 06-0261.” Pipeline and Hazardous Materials Safety Administration, 6 Apr 2007. https://www.phmsa.dot.gov/regulations/title49/interp/06-0261

- GoShip. “How to Ship an Engine: An Ultimate Guide.” GoShip Blog, 12 Mar 2024. https://www.goship.com/blog/how-to-ship-an-engine-an-ultimate-guide/

- Emotrans Global. “Freight Class Guide.” Emotrans Blog, 11 May 2023. https://www.emotrans-global.com/blog/freight-class-guide/

- TSI Shipping. “How Do I Ship Engines & Transmissions?” TSI Resource Center, 2025. https://www.tsishipping.com/resource-center/how-do-i-ship-engines-transmissions

- TransLogistics Inc. “Who are the Largest LTL Freight Companies?” TransLogistics Blog, 18 Jun 2024. https://www.translogisticsinc.com/blog/who-are-the-largest-ltl-freight-companies

- Kuebix. “The Top Freight Companies: LTL & FTL Carriers.” Kuebix Resources, 2 May 2025. https://www.kuebix.com/ltl-ftl-freight-companies/