When inventory languishes on shelves and doesn’t sell, it slowly eats more and more of your revenue. ECommerce brands like yours can avoid some of that risk by adopting kitting operations that combine well-loved and slow-moving goods, clearing more off warehouse shelves, and giving customers a great deal. It’s a reliable way to protect your business against multiple threats.

Kitting is a growing value-added service from companies like Red Stag Fulfillment because we have the space and expertise to create and securely ship kits accurately. After a tumultuous 2020 and 2021, more brands are looking to kits to control inventory costs and expand their sales opportunities. So, we will look at kitting operations and what benefits companies can achieve when they start combining goods for a brand-new offer.

Keep reading below to learn more about:

- Kitting operations definition

- What the kitting process includes

- 5 benefits of kitting your SKUs

- How partners can help you get started

Kitting operations defined

When a 3PL like Red Stag Fulfillment talks about kitting operations, we’re including everything in the kitting process plus elements that support it. Surprisingly, that all starts with a conversation. When a company like yours is interested in kitting products together, we talk about what to include, how you want these products presented, and what should be done to maintain branding and a positive customer experience.

It tracks kits from order and creation through packing and shipping. We’ll build a procedure for your specific kit assembly designed to streamline the process while ensuring goods are protected. The goal is a better delivery experience.

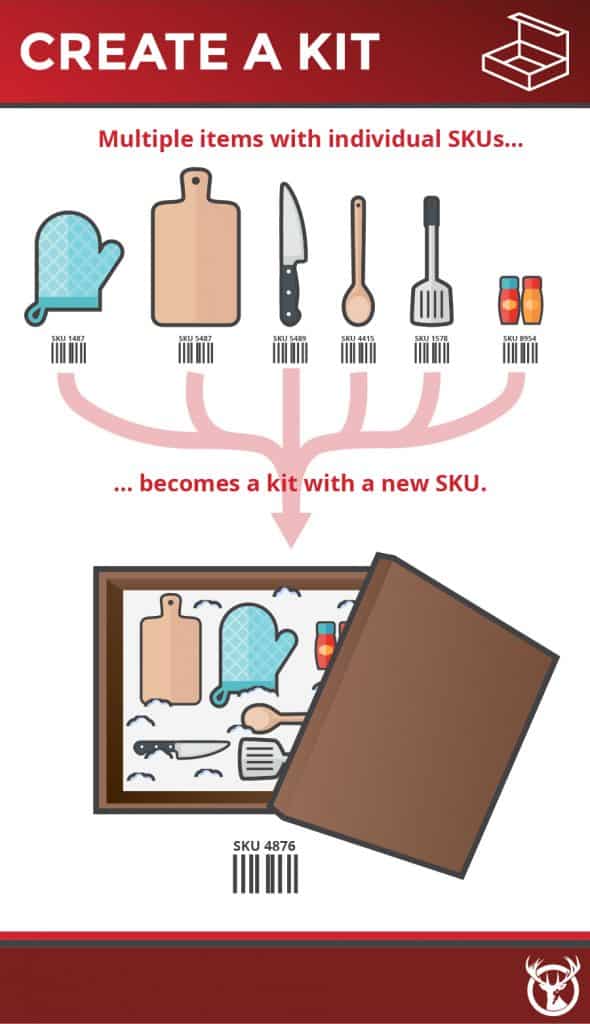

That conversation also helps flesh out your kitting operations, including how systems count these orders. In most cases, we’ll create a new SKU to note kits. That way, you can see and track when we use inventory to create a kit, just like when it’s used to fill a direct sale. Our approach makes it easy for you to restock at the right moment, so you’re not at risk of running out but also not storing too much inventory for your order volumes.

Optimizing inventory has become increasingly important during the COVID supply chain days. See our recent post on long-term storage to understand better those concerns and risks that slow-moving inventory can present to your business.

Steps of the kitting process

Kitting operations cover multiple steps, some of which are always done by you and others performed by the pick and pack teams. Thankfully, the kitting process is straightforward and easy to duplicate for new kits once the original is plan is crafted. Here’s what kitting operations should cover first if you’re kitting yourself and not kitting in the manufacturing process.

Foundational steps

- Create the kit blueprint. Here you’ll define what items can go into your kit. Set this up in your inventory and order tools based on current SKUs so that pickers know what pick. You may need to create multiple versions for similar products, such as having options denoting different sizes or colors of items like apparel.

- Form a packing plan. Determine what boxes and infill you’ll use for your kits. Think about branding opportunities such as custom tape or paper. Share this with your team or 3PL — Red Stag and others can add these details into order management tools so that pickers always see what’s required when they receive a kit order.

- Assign each kit option a unique SKU within your inventory system. This allows you to better track inventory usage and kit sales. You can better track product levels and tell what kits are generating sales.

- Gather the materials. Ensure that you’ve got everything you need in the same warehouse to create each kit. These kitting operations cover products as well as packaging materials, inserts, and anything extra you plan to include.

- Start the offer. Load kit options into your order management tools and sales channels so customers can start shopping for your kits! But be sure to test orders and fulfillment with a few in-house purchases first to ensure everything works correctly.

Order-based steps

After the foundational steps are complete, you’ll need to prep yourself for when orders start to arrive. Here’s what kitting operations includes when someone buys from you.

- Order for a kit is received. For kits, orders tend to happen in one of two ways: 1) someone orders the individual kit, and 2) someone subscribes to a subscription service, and you create on kit per subscriber on a specific date.

- Collecting items. No matter how you receive orders, the product steps for the kits are the same. First, a picker will receive the order for a kit and will pick every item for it off warehouse shelves. These are all brought to a staging area or packing table.

- Packing items. Now, packers collect each item, scan them, and put them into a single package per your kitting operations blueprint and packing plan.

- Scanning and printing. With the kit created, it should be scanned into the system as a single SKU. Then, based on the individual order or your plan, create the appropriate shipping label to have it arrive on time, affordably.

- Ship and delight. Finally, the packing expert will apply the correct shipping label and move it to a staging area where the suitable carrier will pick up the package. Then, it’s shipped to the customer to delight them with their new favorite kit.

Read more about Red Stag’s kitting processes and offers here.

5 simple benefits of kitting operations for SKUs

ECommerce companies can leverage kits for a variety of benefits and objectives. You may want to increase sales, avoid losses, shift products from a ‘slow-moving’ status, or simply clear off shelves. Here are five direct benefits that nearly all companies can achieve when they start creating kits.

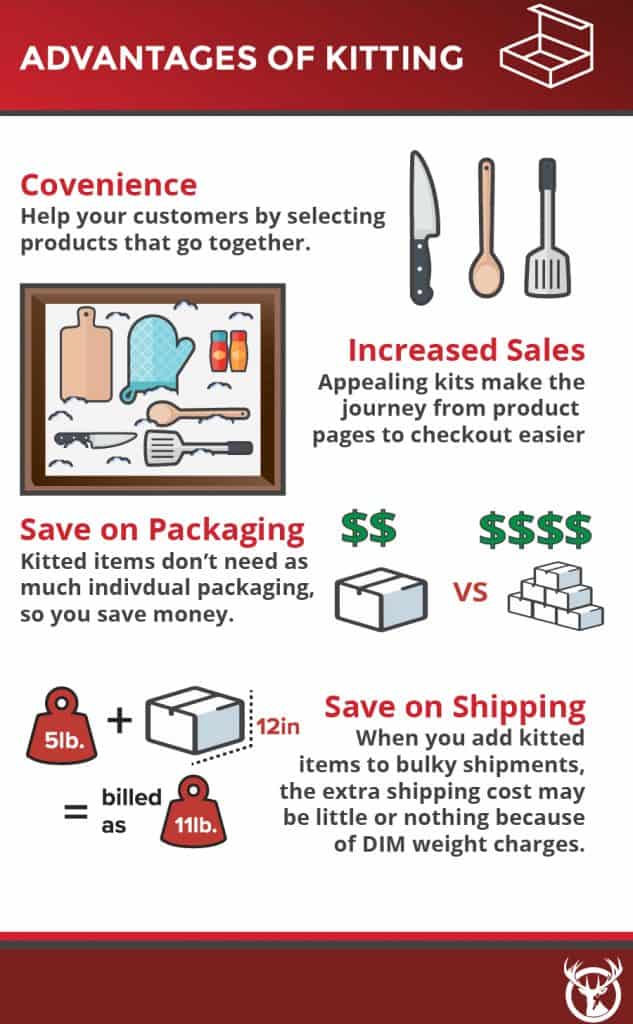

1. Increase product sales

First and foremost, kitting is a growing sales strategy. It helps you tackle revenue in a few different ways. Combining related items gives shoppers an immediate way to get what they’re interested in plus a little extra — it comes off as a deal to them, while being an upsell opportunity for your business. This isn’t just about selling batteries with electronics; you can kit items that enhance the versatility of your core product.

And customers love kits. If they’re buying a gaming chair from you, why not give them an option to instantly add in the best lumbar support pillow or fabric cleaning bundle?

Kits can also prime your shoppers for subscription offers. Showing your goods in a packaged format can make on-page offers for subscriptions more compelling because customers get a clear idea of the offer. And you can even sell those subscription boxes separately as kits.

2. Improve product flexibility

Product demand fluctuates for most eCommerce brands. Not only do you face general seasonality, but competition and changes to consumer demand can spike overnight. You want to tackle that as much as possible, and kits provide a simple way to combat losses. Kitting seasonal products, loss-leaders, or those that have become slow-moving can help you clear out lagging inventory while generating revenue.

This improves sales and reduces costs around long-term storage, spoilage, and other concerns. Kits are a great way to keep products moving even during their off-season.

3. Reduce fulfillment costs

In many cases, eCommerce companies find it cheaper to ship products in as few boxes as possible. That means getting someone to buy two items from you and sending them in a single box will often be less expensive than selling and shipping each item individually. This can allow you to give customers a discount while you generate more revenue by not having to pay a second shipping cost to your selected carrier. Using a single box also reduces material and labor costs if you’re self-fulfilling. Working with a 3PL will also help you lower costs because often you’ll pay a much smaller fee for adding additional SKUs to an order than shipping two separate orders.

4. Reduce fulfillment risks

Kitting also has a chance to reduce risks to products during the fulfillment process. By putting more products in fewer packages, your goods are handled less in transit and are less likely to be damaged. Kitting with a professional 3PL like Red Stag also ensures that your kits packaging is tested. We’ll collaborate with you to provide the proper boxes, filler, and other packaging elements to help your goods arrive in-tact and on-time, every time.

5. Improve operational efficiency

Kitting operations tend to reduce the overall activity required to ship multiple SKUs. They’re picked and packed together, assembled, and shipped out to customers in fewer boxes. All these actions streamline your fulfillment processes, reducing the chance for mistakes and increasing the speed of order completion. Kits can make operations more efficient while reducing expenses.

Auxiliary processes are faster, too. Creating standardized kits allows you to prep for exact weight and shipping requirements, improving budgeting and giving you a chance to streamline spending. When expert workers are focused on kitting items, they also move faster and can ensure fewer mistakes. That limits the chance of a return, helping you secure the revenue you’ve generated.

How a kitting operations partner can help

Kitting operations provide simple, effective ways to improve your inventory usage and fulfillment strategy. You’ll be able to streamline operations and sales while better controlling costs and even avoiding risks like long-term storage fees. Kits can help you tackle multiple risks. Reviewing SKUs and sales regularly, then developing the proper kit response will make it easy for brands like yours to address even uncertain customer preferences and supply chains.

Red Stag Fulfillment offers customized fulfillment capabilities for today’s leading eCommerce companies, including kitting operations. Our experts are here to help you make a complete fulfillment plan from storage and packaging to carrier selection and returns management. We offer leading guarantees for standard and value-added services designed to turn your fulfillment into a competitive advantage. And it all starts with a click.