Whether you’re shipping an office chair you sold on Facebook Marketplace or 100 orders a week for your ecommerce business, finding the cheapest way to ship large packages is challenging. With changing rates, size-related surcharges, and various discount platforms, the variables can be overwhelming.

Drawing from 12 years of specialized experience in handling large shipments, this guide compares actual carrier rates for oversized packages across different distances and shipping speeds.

We’ll also explore nine strategies to ship bulky items affordably while avoiding common costly mistakes.

TL;DR:

Key takeaways

The cheapest way to ship large packages domestically is via UPS and USPS ground services, booked through shipping platforms at discounted rates.

Shipping platforms offer lower rates than direct carrier pricing, but they typically don’t guarantee delivery times or provide compensation for delays.

USPS’ next-day shipping services are more affordable than those of UPS and FedEx for most large shipments.

USPS has lower maximum size and weight limits than UPS and FedEx, which eliminates it as an option for some oversized packages.

The most affordable way to ship large boxes internationally is by booking through shipping platforms, though the lowest carrier rates vary by destination.

What you’ll learn

The cheapest way to ship various large packages by parcel type and transport distance

Exact carrier rate comparisons for three packages across five routes

Main factors that affect total transport costs, beyond the base carrier rates

Nine proven strategies to lower the cost of shipping large packages

PRO TIP: Running an ecommerce business that ships large packages? Specializing in big, bulky, and heavy fulfillment services, Red Stag Fulfillment can do the heavy lifting for you. Learn more about our 3PL services today.

Carrier-rate comparison for large boxes and oversized packages

The following tables compare carrier rates for three different large packages (i.e., a dumbbell, portable air conditioner, and home safe) across five domestic and international routes, including both ground and next-day services.

For easy comparison, black bold figures show the cheapest option when booking directly with carriers, while red bold figures indicate the lowest rate across all options—including both direct carrier booking and a representative discount platform (PirateShip).

You’ll find complete package dimensions and weights listed after the domestic shipping tables.

Cost comparison for shipping a dense 45-lb package (dumbbell)

| Company | Los Angeles to Phoenix, ~370 miles | Los Angeles to Boston, ~3,000 miles | ||

|---|---|---|---|---|

| Lowest rates for ground shipping | Most affordable next-day service | Lowest rates for ground shipping | Most affordable next-day service | |

| USPS | $84.70 | $327.00 | $151.45 | $407.85 |

| UPS | $77.41 | $475.82 | $133.14 | $569.32 |

| FedEx | $76.95 | $496.11 | $157.81 | $619.22 |

| PirateShip | $39.23 | $166.22 | $65.26 | $203.34 |

Cost comparison for shipping a large, bulky package (portable AC)

| Company | Los Angeles to Phoenix, ~370 miles | Los Angeles to Boston, ~3,000 miles | ||

|---|---|---|---|---|

| Lowest rates for ground shipping | Most affordable next-day service | Lowest rates for ground shipping | Most affordable next-day service | |

| USPS | $97.95 | $393.70 | $173.85 | $491.30 |

| UPS | $87.80 | $549.17 | $152.17 | $579.33 |

| FedEx | $81.39 | $656.27 | $175.91 | $877.00 |

| PirateShip | $42.34 | $196.66 | $71.34 | $240.58 |

Cost comparison for a 110-lb oversized box (home safe)

| Company | Los Angeles to Phoenix, ~370 miles | Los Angeles to Boston, ~3,000 miles | ||

|---|---|---|---|---|

| Lowest rates for ground shipping | Most affordable next-day service | Lowest rates for ground shipping | Most affordable next-day service | |

| USPS | too heavy to ship* | too heavy to ship* | too heavy to ship* | too heavy to ship* |

| UPS | $223.61 | $1,252.12 | $284.22 | $1,460.43 |

| FedEx | $244.63 | $1,178.89 | $332.13 | $1,773.95 |

| PirateShip | $104.49 | $419.60 | $135.90 | $514.65 |

NOTE: *The weight of the home safe exceeds USPS’ limit for parcel shipping, which is 70 lbs.

NOTE: Details of the assumed packages used in the calculations are:

• Dumbbell (45 lbs, 20″ x 20″ x 13″): dense package—heavy for its size.

• Portable AC (50 lbs, 30″ x 20″ x 15″): bulky package of medium density

• Home safe (120 lbs, 30″ x 30″ x 20″): large, heavy, oversized package

Cost comparison for international shipping of a large package

The table below compares international shipping rates for the portable AC (50 lbs, 30″ x 20″ x 15″) across three common international routes.

| Company | Los Angeles to Vancouver (continental, ~1280 miles) |

Los Angeles to London (intercontinental, ~5,440 miles) |

Los Angeles to Sydney (intercontinental, ~7,500 miles) |

|---|---|---|---|

| USPS | $238.05 | $302.75 | too large to ship* |

| UPS | $154.04 | $1,048.66 | $1,524.58 |

| FedEx | $159.13 | $1,155.87 | $1,920.68 |

| DHL | $470.95 | $877.48 | $1,215.09 |

| PirateShip | $70.49 | $215.10 | $331.38 |

NOTE: *At 100″ in combined length and girth (2 × width + 2 × height), this package exceeds USPS’ maximum size limits for shipping to Australia, which is 97″ in combined length and girth.

Key factors affecting the shipping costs of large packages

Understanding how multiple factors combine to determine your final shipping costs is essential for long-term cost management. Beyond the base carrier rates, several variables can dramatically increase your shipping bill, potentially adding thousands to the expected cost.

Here are the key cost drivers so you can anticipate, calculate, and minimize these expenses.

Distance

01

Carriers use shipping zones to calculate costs based on how far your package travels. Each zone represents a distance range, with higher zone numbers meaning greater distances and higher costs.

However, shipping zones aren’t standardized across carriers, creating the potential for costly miscalculations when comparing rates. What UPS calls Zone 5 might be Zone 6 for FedEx, leading to unexpected price differences.

NOTE: The same carrier often defines zones differently for different services. UPS uses 10 zones for Next Day Air service but only seven zones for Next Day Air Saver. The additional zones in Next Day Air account for territories outside the contiguous United States, like Puerto Rico and Hawaii.

Flat-rate vs. distance-based prices

Flat-rate shipping allows you to send packages anywhere in the contiguous United States for one fixed price, regardless of distance. The rate offers predictable shipping costs, whether you’re sending a package across town or across the country.

However, flat-rate shipping models vary by carrier. While UPS and USPS offer true flat-rate options, FedEx One Rate uses a hybrid pricing system with three distance tiers: local, regional, and national.

With that said, most large packages exceed flat-rate size restrictions. Here’s what USPS and UPS offer:

- USPS provides free predefined flat-rate boxes. They offer two large options:

- Top-loading box: 12.25″ x 12″ x 6″

- Side-loading box: 15″ x 15″ x 3.125″

- UPS Simple Rate is more flexible for large items. The program allows your own packaging up to one cubic foot (1,728 cubic inches). Here are a few examples of qualifying box sizes:

- 16″ x 12″ x 9″

- 12″ x 12″ x 12″

- 18″ x 12″ x 6″

Dimensional vs. actual weight of large packages

02

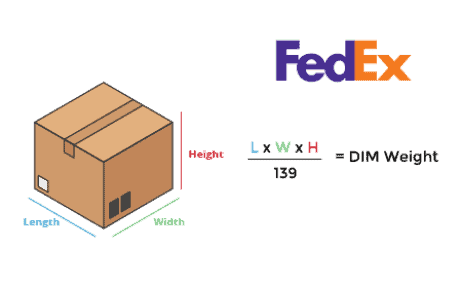

Dimensional weight is a pricing method that carriers use to calculate shipping costs based on a package’s dimensions, rather than its actual weight.

Dimensional weight formula and divisor

To calculate the dimensional weight of your box, use the following formula: length × width × height ÷ dimensional weight divisor (166 or 139)*. If the resulting value is greater than the actual weight, carriers will use it to assess shipping costs.

For example, if you’re sending a retail package that measures 30″ x 20″ x 20″ and weighs 10 lbs, USPS and UPS will charge for shipping based on the package’s dimensional weight of 73 lbs (30 × 20 × 20 ÷ 166, rounded up).

For the same shipment, FedEx will bill you based on a dimensional weight of 87 lbs (30 × 20 × 20 ÷ 139, rounded up).

*NOTE: Dimensional weight divisor factors vary by carrier. USPS uses 166, FedEx uses 139, and UPS uses both, i.e., 166 for retail and 139 for commercial shipments with scheduled pickups. To determine the billable weight of your package, use our dimensional weight calculator.

Delivery speed and mode of transport

03

The most affordable way to ship large packages is ground transport.

For example, shipping the aforementioned portable AC from Los Angeles to Phoenix via ground services costs between $80 and $100. In contrast, if you opt for next-day air transport, you’ll pay $300 to $700, depending on the carrier and service.

NOTE: The most expensive options are next-day services with early delivery, such as FedEx First Overnight or UPS Next-Day Air Early. If possible, plan your shipments in advance to avoid paying premium rates for these expedited services when shipping large packages.

Chosen carrier

04

UPS and USPS typically offer more affordable shipping options than FedEx for large packages.

Apart from the pricing policy, FedEx charges higher rates because their dimensional weight divisor (139) is lower than UPS’ and USPS’ (166), which results in higher billable weights for the same package dimensions.

Moreover, some of the most prominent shipping platforms (like PirateShip) only offer discounts for UPS and USPS, which further widens the cost gap.

Size and weight surcharges

05

If your package exceeds certain dimension thresholds, carriers might refuse the shipment or add a surcharge for it. Below are a few examples of such surcharges.

Example 1—USPS oversized price: USPS will use a special pricing tier for oversized items with a combined length and girth between 108″ and 130″. Learn more in our guide on USPS Oversized fees.

Example 2—FedEx Additional Handling fee: FedEx will add an additional-handling surcharge if any of the following thresholds are breached:

- Longest side exceeds 48″

- Second longest exceeds 30″

- Combined length and girth exceeds 105″

Learn more in our guide on FedEx oversized fees.

Example 3—UPS Overmax fee: If a package exceeds the maximum allowed size or weight and is found in the UPS parcel system, it incurs a steep penalty surcharge—the Over Maximum Limits fee of $1,325. Learn more in our guide on the UPS Overmax fee.

Both USPS and FedEx have similar surcharges for items that exceed their size limits. Refer to the carrier’s maximum size thresholds below to avoid these fees.

| Size and weight limits for shipping a large package | UPS | FedEx | USPS |

|---|---|---|---|

| Length and girth combined | 165″ | 165″ (130″ for Express) | 108″ (130″ for Retail Ground, charged as oversized) |

| Length | 108″ | 108″ | * |

| Weight | 150 lbs | 150 lbs | 70 lbs |

Shipping vs. freight transport cost

06

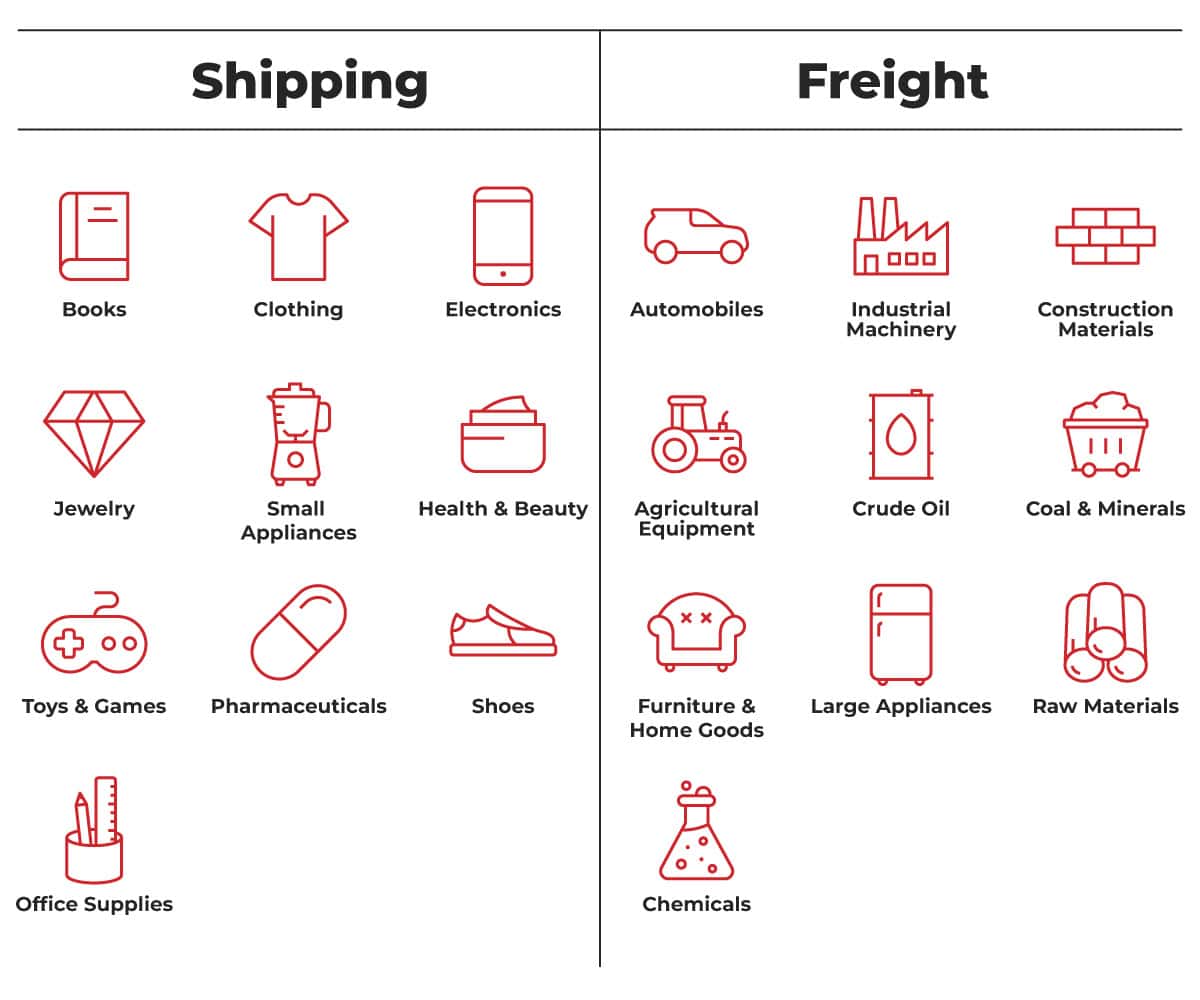

If your package exceeds the previously mentioned size limits, you can send it as freight, which means your item will be loaded onto a pallet and moved with other large items.

Even though palletized freight typically costs more than standard shipping, it allows you to avoid size surcharges and reduces the damage risks associated with parcel shipping.

The illustration below shows items that are commonly transported via shipping and freight. Learn more in our comparison guide on shipping vs. freight.

PRO TIP: For large packages that exceed parcel shipping limits but don’t require a pallet, you can lower the transport cost by using specialized services for non-palletized freight, such as UPS Ground with Freight Pricing or UPS Hundredweight.

Coverage and insurance

07

Carriers provide free coverage up to $100 for lost or damaged packages. If your item is worth more, you have two options for additional protection.

Carrier declared-value coverage

You can increase your declared value with the carrier and pay 1% to 2.5% of your item’s worth for additional coverage.

For example, if the aforementioned portable AC costs $500, you’d pay $5 to $12.50 extra to declare its full value with the major carriers.

Third-party shipping insurance

For valuable items, third-party insurance often provides better protection than carrier coverage. While it may cost more up front (0.5% to 4% of your item’s value), it typically offers more comprehensive coverage with fewer restrictions.

Using the same $500 AC example, third-party insurance might cost between $2.50 and $20.

NOTE: Declared value is your assessment of your item’s monetary worth. It sets the maximum amount the carrier will pay if your package is lost or damaged. Keep in mind that declared value isn’t true insurance. Rather, it comes with exceptions and limitations that may not fully protect your investment.

Packaging materials

08

Unless the item can be shipped in its original box, the protective materials for large shipments vary in cost, depending on the item’s fragility and whether you already have supplies on hand.

Let’s assume you’re shipping a large, fragile picture frame measuring 40″ × 20″ × 10″ and need to purchase protective materials. The table below shows the cost of buying each packaging supply in typical retail quantities (for example, a full roll of packing paper or a pack of corner protectors).

| Packaging supply | Projected cost |

|---|---|

| Cardboard sheets | $15–$30 |

| Corner protectors | $10–$20 |

| Packing paper | $10–$20 |

| Acid-free glassine paper | $15–$30 |

| Packing tape | $5–$10 |

NOTE: For ecommerce businesses, the generally accepted cost of packaging materials is 1% to 3% of the product’s wholesale price, with premium brands allocating up to 10% for enhanced unboxing experiences and protection.

Tips to lower the shipping costs for large boxes

The following nine strategies can help you cut shipping costs for large boxes by 20%–80%, depending on your current shipping methods. These proven techniques range from simple packaging adjustments to advanced carrier negotiations and alternative shipping solutions.

Optimize the packaging

01

Large, lightweight packages are almost always charged based on dimensional weight rather than actual weight. You can reduce shipping costs by packing the contents more compactly.

To illustrate the potential savings, let’s say you’re shipping a boxed office chair that measures 25″ x 22″ x 35″ and weighs 50 lbs.

If you ship the chair assembled, the billable weight will exceed 100 lbs. However, if you disassemble the chair and pack it into a box measuring 21″ x 18″ x 18″, the dimensional weight of the package will be 41 lbs or 49 lbs, depending on the carrier. In this scenario, the shipping costs will be based on the actual weight.

The table below compares UPS ground shipping rates from Los Angeles to Boston for the two packaging approaches.— —

| UPS Ground rates—Los Angeles to Boston | |

|---|---|

| Packaging method | Rates |

| Assembled chair (25″ x 22″ x 35″ box) | $259.09 |

| Disassembled chair (21″ x 18″ x 18″ box) | $143.65 |

| Total savings | $115.44 (44.6% reduction) |

Send at discounted rates through shipping platforms

02

Shipping platforms like PirateShip offer volume-based discounts because they negotiate lower rates with the carriers. In some cases, these discounts can be as high as 80%.

However, these platforms might not provide the same service level. For example, they often don’t guarantee arrival times, which introduces a higher risk of nonrefundable loss if shipments are delayed.

BOTTOM LINE: For one-off shipments where timing is flexible, discount platforms are an excellent way to save money when shipping large boxes. But if you’re running an ecommerce business that relies on accurate and timely shipping, carefully weigh the cost savings against the lack of delivery guarantees before choosing a discount platform.

Find the cheapest option on shipping aggregators

03

Shipping aggregators and marketplaces, like uShip, connect shippers with carriers through the following steps:

01

The shipper posts a job.

02

Carriers bid on it.

03

The shipper compares rates and reputation and potentially hires a carrier.

BOTTOM LINE: For some large packages, local trucking companies or courier services might offer lower rates than the major carriers, especially for regional deliveries.

Avoid surcharges when shipping bulky items

04

Size- and weight-related surcharges can exceed the base shipping rates for large packages. In some cases, these fees can add thousands of dollars to your shipping invoice.

To avoid the added costs, plan your shipments strategically and with attention to detail. Here are a couple of tips to minimize the risk of incurring a surcharge.

Familiarize yourself with carrier policies

Take the time to study the size limits and the potential surcharges. Make sure you understand how these fees are triggered, their current rates, and the potential impact on your bottom line.

Measure accurately and allow for safety margins

Packages can shift and change dimensions in transit. To mitigate the risk of these changes triggering a surcharge, package your shipments so their dimensions stay well below surcharge thresholds.

For example, if you’re shipping via UPS, avoid packing your item in a box that exceeds 160″ in combined length and girth, as 165″ is the threshold for the Over Maximum Limits fee.

This approach also allows you to avoid the surcharges for inaccurate measurements that some carriers impose, such as USPS’ Dimension Noncompliance Fee for commercial shipments.

PRO TIP: Use standard boxes that don’t trigger surcharges. This allows you to predict shipping costs and avoid unexpected expenses.

Use the carrier calculators instead of rate sheets

05

While the rate sheets published by carriers are useful for tracking price changes, they require a deep understanding of the size limits and zone splits. For this reason, they leave more room for error and omission when assessing shipping costs.

Instead of relying on the rate sheets, contact the carriers directly or use their calculators for accurate cost assessments. The following calculators automatically apply all relevant fees, surcharges, and zone-based pricing:

Ship out of peak season

06

If possible, reduce your shipping volume during the peak season (October to mid-January) to avoid higher carrier rates and demand surcharges.

For example, FedEx’s Oversized Charge* is $205 outside peak season. Around Christmas, FedEx will also charge the Demand–Oversize Charge of $100, which brings the total added cost for oversized packages to $305—a 49% increase.

If you need to ship packages during these peak-demand periods, book and pay early to secure your space and avoid last-minute price increases.

*Applies to packages that exceed 96″ in length or 130″ in combined length and girth.

Explore bulk discounts

07

If you’re an individual retail shipper, you can only benefit from volume-based discounts through a shipping platform.

However, if you’re running a business and consistently ship at scale, you might qualify for carrier discounts directly. The qualifying shipping quantities are usually tiered. That is, the more you ship, the greater the discount.

Still, most ecommerce businesses don’t ship high enough volumes to qualify for bulk discounts directly with carriers. If you fall into this group, you may still be eligible for lower rates through commercial programs, such as USPS Small Business Solutions.

Consider partnering with a third-party logistics (3PL) provider

08

If you’re running an ecommerce business that ships in bulk but doesn’t qualify for quantity-based carrier discounts, consider partnering with an experienced 3PL provider.

Red Stag Fulfillment specializes in big, heavy, and bulky fulfillment, which allows us to negotiate lower carrier rates for oversized packages through our combined shipping volume.

Partner with us to leverage our carrier relationships and fulfillment expertise. Explore our 3PL services or contact us today for a custom quote.

Split large shipments into small packages

09

If your package exceeds size thresholds and triggers surcharges, splitting it into multiple smaller parcels might lower the shipping cost.

For example, a package that measures 35″ x 30″ x 20″ would incur a FedEx Oversized Charge because the combined length and girth exceed 130″.

However, splitting the contents into two boxes that measure 30” x 25” x 14” each allows you to ship the same volume (21,000 cubic inches) without triggering the Oversized Charge.

The downside and the solution

The downside of this approach is the complexity of calculating costs for different packaging scenarios. The solution is a program like FedEx Multiweight.

Once activated on your account, FedEx Multiweight automatically compares the cost of multiple smaller packages versus one consolidated shipment and then applies whichever rate is lower.

NOTE: FedEx Multiweight only applies to packages with the same origin and destination address, but it offers a separate tracking number for each package, even for consolidated shipments. Learn more on the FedEx website.

Level up your business with the right partner

If you’re running an ecommerce business that ships large packages, partnering with the right 3PL provider can be a significant advantage.

Red Stag Fulfillment specializes in large and heavy shipments, which allows us to negotiate volume-based discounts with the carriers. As our partner, you’d benefit from these discounts and fulfillment guarantees, including zero shrinkage and order accuracy.

We handle the fulfillment; you focus on growth.

Contact our team today to start a conversation.