Having the right warehouse locations can improve several aspects of your ecommerce business. Getting closer to your customers reduces shipping times and optimizes landed costs. But there are a few other factors worth noting.

Too many fulfillment centers may cannibalize the benefits of a geographic strategy, requiring you to invest in higher overall inventory volumes and freight costs.

A limited number of centrally located warehouses can lead to lower carrying costs and more reliable transportation networks.

How you handle inventory management matters, too. The right locations and partners can create a streamlined fulfillment network, but if you’re spread too thin, costs may quickly rise.

In this article, you’ll learn more about how to choose fulfillment center locations, including how to leverage geographic advantages with a fulfillment company. This information can help you improve your logistics and increase profitability.

Why fulfillment center locations matter

Strategically placed fulfillment centers can help you reduce landed costs and shipping times while driving customer satisfaction and loyalty. Working with a fulfillment company may make it easier to identify opportunities and take action.

Coastal vs. inland fulfillment center locations

If your ecommerce company is headquartered on the East Coast or West Coast, you may think it’s best to pick from warehouses or fulfillment centers nearby. This is a common misconception that could be costing you.

Coastal fulfillment centers are more likely to struggle with capacity constraints than inland fulfillment centers. There’s limited physical space in these regions. That means these fulfillment centers are priced on scarcity and inflation, not value. You may pay too much to store more inventory in such a crowded area.

Congestion carries risk, too. Even when you meet delivery promises, it can involve a high number of touchpoints because carriers may route around areas that are more prone to bottlenecks. These extra handoffs or longer routes can add more costs than you’d see with inland fulfillment services.

You can avoid these risks by routing freight from ports to an inland fulfillment center away from the coast. Remember, fulfillment companies can work with you no matter where your offices are.

On-time warehouse fulfillment

Fulfillment center locations can help you meet customer delivery expectations, too.

Peer-reviewed research in Manufacturing & Service Operations Management finds that customers expect deliveries within two days. If it takes longer, they’re disappointed with your brand (not the shipping carrier).

Delivery times are dependent on many factors, but distance is a big one. Inland fulfillment center locations that are nearer to your customers may help streamline fulfillment services and shorten shipping times.

Strategically placed shipping warehouses may also lead to simpler routing. Fewer carrier handoffs across fewer fulfillment center points can reduce complexity, cost, and risk of delays.

The logistics routing may be challenging for some businesses to handle, but a fulfillment company can help.

Customer expectations and profitability

Meeting customer delivery expectations helps drive revenue growth and cost reduction.

With other positive factors in place, satisfied customers are likely to make repeat purchases. Some may become loyal advocates. They contribute to your growth with positive reviews, personal referrals, and social media engagement.

This loyalty not only boosts topline revenue but can minimize customer acquisition costs. As brand affinity levels grow, continuing to ship accurately and on time from a reliable fulfillment center helps promote further loyalty and advocacy.

You may have an easier time kick-starting this cycle with streamlined logistics and fulfillment services.

The best location for your fulfillment warehouse

Your fulfillment center locations can depend in part on the maturity of your business.

Startups tend to hold inventory in fewer shipping warehouses than established ecom companies. Other companies may split stock between in-house storage and 3PL fulfillment centers.

Here, we’ll quickly review how your business evolution could impact your inventory management across local fulfillment centers.

Growing into multiple warehouses

Many businesses begin their operations with a single fulfillment center, providing a straightforward and manageable approach to order fulfillment.

But as your business grows, a single fulfillment center may no longer cut it. Higher demand may lead you to expand into more than one warehouse fulfillment center.

Strategic moves to a fulfillment company with more centralized geographies may make it easier and more cost-effective to cater to a broader customer base.

Risks of splitting stock

As you distribute inventory, be aware of common pitfalls. Splitting stock across too many fulfillment centers can introduce new risks, making it more complex and costly to fill customer orders.

Carrying costs may escalate, impacting the overall financial health of your business.

Management and logistics may become overly complex, sucking up resources.

If you forecast incorrectly, inventory may be in the wrong warehouse, multiplying costs.

By balancing these factors, you can develop a warehouse location strategy that prioritizes customer proximity and landed costs.

Finding 3PL warehouse space near customers

Once you understand how to distribute stock appropriately, you can narrow down which fulfillment center locations might work best for your business.

At this stage, many ecommerce companies shop for a 3PL fulfillment company that aligns with their geographic needs and provides a variety of supply chain and fulfillment services.

Bringing inventory closer to customers

Your customer geographies may change with time. For example, a local business may expand into a national one. Or, customer orders might come in from new regions. For established companies, regional demand may also change based on seasonality or product introductions.

But you can’t just switch your fulfillment center locations every time demand grows or shifts. The cost and effort would eat up the equity in your growth.

This is one of the reasons why centralized fulfillment center locations are well-suited for long-term partnerships.

Meeting customer demand anywhere

Consider the fictional example of Toni, owner of Tropical Treats in Miami. She began selling confections to local stores but received requests to ship nationally, so she opened an online store.

As she grew, she faced a common challenge. Some customers were leaving reviews like, “Worth the wait!” but she was experiencing high shopping cart abandonment rates due to extended delivery times. Shipping costs were also more than she could handle for the long term.

She was relying on her production facility and warehouse space in Miami to double as her fulfillment center, but their services were no longer sufficient.

Toni opted to work with a 3PL fulfillment company that had warehouses strategically positioned around the center of the country. Her new multi-warehouse strategy let her scale production and deliver perishable food products quickly.

Customer satisfaction improved, and Toni was able to continue growing her line of confections, thanks to her new fulfillment center and its strategically located warehouse space.

Local fulfillment centers and delivery time

If the story of a company struggling to meet demand resonates with your own experience, it may be time to optimize deliveries with more strategic fulfillment center locations, especially if you’ve seen competitive market changes like the ones discussed below.

Competitive impact of fast fulfillment stores

Online stores may find that customer expectations are continually growing because big market players always seem to raise the bar.

Marketplaces like Amazon have customers hooked on same- and next-day delivery. Major nationwide retailers are in on the action, too, delivering their own products quickly from a massive fulfillment center network. They may also sell products from drop shippers and self-fulfillment brand partners, each with their own fulfillment center operations.

The rise of local delivery apps has placed brick-and-mortar retailer stores back on the map, too. In these cases, a fulfillment center stocks a store, and a hired shopper delivers items to customers.

The customer experience is the same—or better—when they can order from a national retailer and have the item at their address in a few hours or less.

Leveraging inland warehouses

The major companies that lead the competition in order fulfillment tend to have a specific location strategy. They maintain sprawling warehouse networks and have at least one fulfillment center embedded locally across population centers. These companies also have the resources and capabilities to manage complex logistics.

But that’s not true for every business, even ones that are run efficiently. Fortunately, there’s a tactic you can use to help level the playing field.

With customers across the U.S., most ecommerce companies eventually route inventory to a fulfillment center inland. Doing it early in the order-to-cash cycle can reduce carrying costs by skipping costly coastal warehouses.

It may also reduce the risks of congestion often found in coastal areas. Moving to an inland fulfillment center, logistics activity is more spread out and less likely to bottleneck.

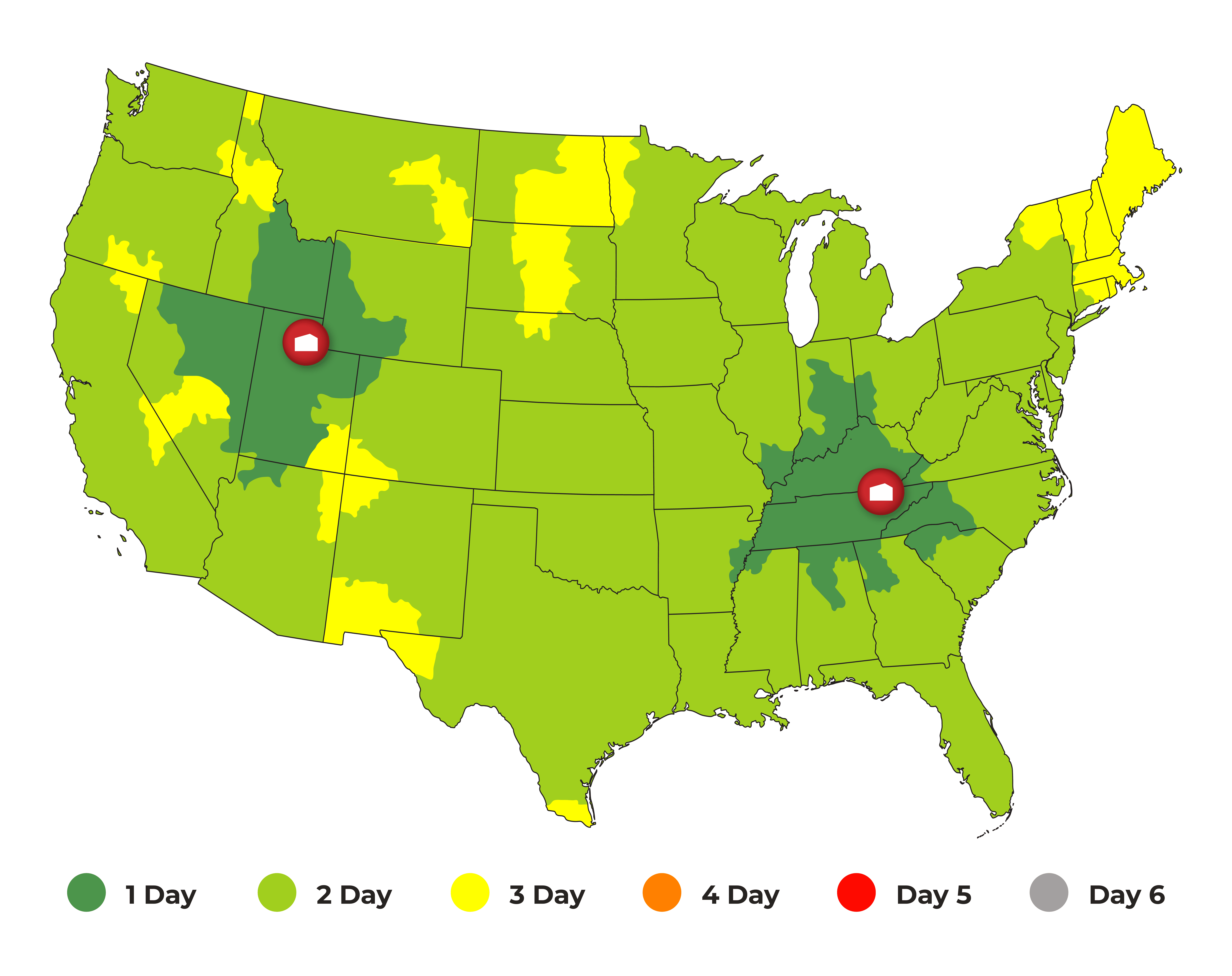

It’s also easier to maintain inventory flow when a larger portion of your customers are closer to the fulfillment center. This can help ensure delivery to nearly every customer within two days without excessive trucking costs.

In other words, an inland fulfillment strategy may help you achieve more on-time shipments and predictable landed costs. And, with today’s high expectations, it can help you compete with brands and marketplaces that have far more resources than you.

Benefits of strategically located 3PL warehouse space

Strategically located 3PL fulfillment centers can yield significant benefits for businesses, particularly in terms of optimizing shipping zones, rates, and overall cost efficiencies.

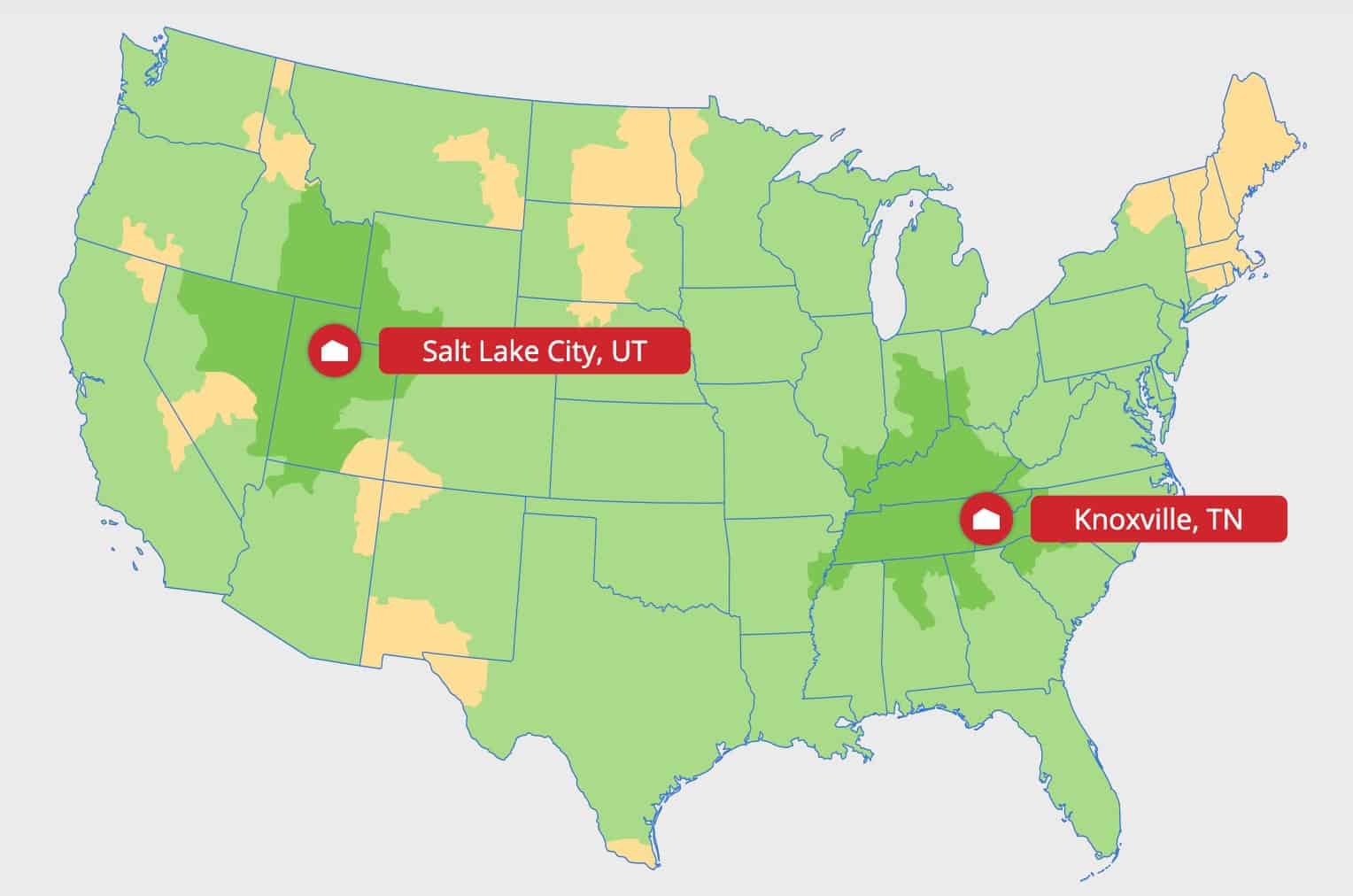

This is why Red Stag Fulfillment locates its fulfillment center warehouses in Knoxville, Tennessee and Salt Lake City, Utah. From these locations, our fulfillment and logistics operations can reach 96% of U.S. homes within two days or less.

The impact of fulfillment center location on speed and efficiency can help you meet evolving customer expectations, even as your customer base grows or regional demand changes.

Shipping zones and rates

One of the key advantages of inland 3PL fulfillment center locations is the reduction of shipping zones and associated costs.

Shipping zones are geographical areas established by carriers to determine pricing based on distance and effort to travel there. Specific zones may vary between shipping carriers, so working with a 3PL fulfillment center that can optimize routing may help you streamline costs.

The general rule is that as a package crosses a higher number of shipping zones, the cost increases.

PRO TIP: You can sidestep some of these costs by storing inventory in 3PL fulfillment centers that decrease the average number of shipping zones between your products and your customer addresses.

Zone skipping

The key to this strategic approach is having inventory closer to customers. This allows for the implementation of zone skipping, which involves palletizing many orders together and shipping in bulk to inland or other regional distribution centers.

Palletization is the process of arranging and securing products on a pallet, which is a flat transport structure with a top and bottom deck. The objective is to efficiently consolidate, protect, and transport multiple items as a single unit.

This lets you take advantage of more cost-efficient freight options rather than spending money on shipping items in smaller orders before they’re sold to customers. Typically, a 3PL or other fulfillment service helps you achieve this.

Landed cost optimization

The cost efficiencies gained through strategic fulfillment centers and zone skipping can be particularly impactful for businesses.

By shipping in bulk and palletizing orders, companies can leverage freight costs more efficiently. The cost-per-unit to ship pallets on a cross-country truck is often offset by or even lower than what is saved on shipping individual orders.

Cost efficiencies created ahead of fulfillment may optimize landed costs and may also present opportunities for you to offer competitive advantages to customers.

Investing in growth

This is where savvy ecommerce leaders can capitalize on choosing the right fulfillment centers for their supply chains.

Optimizing landed costs may help drive sustainable growth. By enhancing supply chain predictability, you can strengthen a foundation for long-term success.

Predictability in operational costs and customer trends may allow you to allocate resources more effectively. Leadership time spent managing overly complex fulfillment can be spent on growth activities such as data analysis and developing insights.

This may promote a culture of continuous improvements and strategic planning. Online store owners and other leaders may be able to identify and capitalize on emerging opportunities.

With improved cash control, you may have a runway for investment in new product variants or the introduction of innovative offerings.

These are advanced tactics that can multiply revenue, all stemming from a shift in fulfillment centers.

Managing inventory across 3PL locations

Most ecommerce store owners want to get their business to the point where they can leverage these sophisticated growth tactics.

You may be able to get there faster by mastering inventory management and stock distribution. The right fulfillment center locations facilitate growth, but maintaining an upward trajectory relies on knowing which products need to be in which warehouse. Let’s look at what that means for your strategy.

Critical role of inventory placement

Strategic inventory placement involves more than just keeping stock in centrally located warehouses. You also need to make sure the right quantities of the right products are positioned to meet regional demands with minimal shipping times.

This may require a deep understanding of your business’s unique demand patterns, including macroeconomic conditions, seasonality, pricing and promotions, competitor activity, and product lifecycle stages.

With a strong handle on these factors, you can help ensure you have products available to align with demand.

Getting this right can be challenging. If you have too little stock in a warehouse location, you could lose sales opportunities and disappoint customers, who may not return. If you store excess inventory in a location, you risk high carrying costs and price cuts to try to urge turnover. This may also degrade your brand.

How to avoid stockouts and backorders

The challenge lies in avoiding stockouts and backorders, which can significantly impact your brand reputation and the overall efficiency of the supply chain.

Using advanced inventory management software is instrumental in addressing this challenge. This software may allow for robust data analysis, enabling you to understand seasonality patterns, regional demand variations, and other critical factors that influence inventory levels.

Documenting seasonality and understanding regional demand patterns are essential to effective inventory management. That’s because forecasting, based on accurate data and insights derived from the software, is also key to the process.

It matters because inaccuracies can lead to cascading effects, prompting businesses to make ongoing adjustments in order quantity and storage locations. These adjustments, if based on inaccurate forecasts, may lead you to miss revenue opportunities, hindering your overall growth potential.

Product availability and 3PL partnerships

To navigate these challenges, many ecommerce companies choose a fulfillment partner based on location and capabilities.

A strategic partnership with a 3PL can go beyond storage and fulfillment services, extending into data-driven SKU analysis, forecasting, and planning. These partnerships may help businesses adapt to dynamic market conditions and capitalize on growth opportunities with precision and efficiency.

Key takeaways for your warehouse location strategy

Here’s a quick summary of key takeaways to consider when developing your warehouse location strategy. You may want to discuss these topics with fulfillment companies to learn how they can support you.

Customer proximity

Choose fulfillment center locations for customer proximity to ensure fast and cost-effective shipping. Selecting inland fulfillment centers lets you reach the largest number of customers within two days, enhancing overall logistics efficiency.

Single vs. multiple warehouses

Startups and businesses with limited products may have their own warehouse or a single fulfillment center at first. As you grow, a phased approach to outsourcing fulfillment or partnering with multiple warehouses can let you scale resources with demand.

Inland warehouses may be best to optimize landed costs because they avoid the high storage rates, competition for storage capacity, and potential for bottlenecks of most fulfillment centers located coastally.

Inventory management

Distributing inventory across multiple locations can minimize shipping zones, leading to faster, cheaper deliveries and happier customers.

PRO TIP: Be wary of spreading inventory too thin, or you could spend more to realign stock with demand or meet shipping time expectations. Fulfillment companies may be able to help with demand planning.

Shipping times

Prioritize fulfillment centers that align with expected delivery times to meet or exceed customer expectations. Satisfied customers can help increase topline revenue and reduce customer acquisition costs, increasing your company’s profitability.

Cost considerations

Balance short-term and long-term costs, including shipping, warehouse fees, and potential expansion expenses. A comprehensive cost analysis ensures financial sustainability, guiding you toward geographic locations that meet your logistical and financial needs.

Your next fulfillment center location

Strategically selecting fulfillment center locations is vital to enhancing various facets of your ecommerce business. Proximity to customers not only reduces shipping times but can also optimize landed costs, playing a pivotal role in driving customer satisfaction and loyalty.

While aiming for geographic advantage, it’s essential to strike a balance. Too many fulfillment warehouses may destroy the exact benefits you’re trying to capture. Complexity and cost creep can derail you.

A limited number of centrally located warehouses is a more prudent choice for unlocking lower carrying costs and accessing a robust transportation network.

Inventory management is also a crucial aspect. The right locations and partnerships create a streamlined fulfillment network, but this is another area where spreading too thin may lead to rising costs. Achieving strategic balance ensures cost efficiency and operational effectiveness.

These factors matter because meeting customer expectations, especially regarding delivery times, continues to be crucial to your success. Strategic fulfillment center locations play a vital role in streamlining the fulfillment process, shortening shipping times, and meeting customer demands.

The interplay between warehouse location, inventory management, and customer expectations directly influences profitability. By leveraging strategic fulfillment centers, you can optimize costs, meet demands, and position your business for sustainable growth.

If you’re ready to take action and improve your fulfillment center locations, Red Stag Fulfillment can help.

With strategic locations in Knoxville and Salt Lake City, our fulfillment warehouse centers exemplify the benefits of strategically located 3PL warehouse operations.

We reach 96% of U.S. homes within two days or less, showcasing the impact of warehouse location on speed, efficiency, and service.

If you have further questions or need assistance navigating the complexities of a warehouse location strategy, reach out to get started.