If there’s one thing my 6+ years of experience as a warehouse manager has taught me, it’s that a good warehouse management system (WMS) is paramount to efficient warehouse operations. And efficiency is everything in a warehouse. When a process is delayed or inventory is mismanaged, the customer feels it the most.

During my career, I’ve worked in countless warehouses and fulfillment centers. From one of the largest jewelry distribution centers in Europe to a small physiotherapy supplies warehouse in New Zealand, I’ve seen and used all kinds of WMS systems.

In this detailed guide, I’ll explain how warehouse management systems work, what they do, and how to implement one in your business.

Warehouse management system definition

A warehouse management system is a software program that automates warehousing processes and tracks warehouse performance data in real time.

Warehouse management systems also improve the accuracy of critical warehouse tasks, such as order fulfillment and inventory tracking.

Here are just some of the disadvantages of not using a WMS:

You’ll have to perform frequent manual inventory checks to understand stock levels

You’ll be assigning labor based on feeling instead of workload and ability

Updates must be entered manually into a spreadsheet every time stock status changes

You’ll lack visibility because your data won’t automatically shared between different departments and teams

With a WMS, stock levels can be ascertained and updated in seconds, tasks are automatically assigned to staff based on their workloads and skill levels, and critical warehouse information is uploaded and stored on the cloud for anyone with access to view or adjust.

The time you can save by implementing a warehouse management system will improve productivity and profitability across the business—keeping your staff, stakeholders, and customers happy.

6 key warehouse management system benefits

The first warehouse I ever worked in took the word ‘traditional’ to a new level.

Forget spreadsheet systems, this place relied on a scrappy clipboard and the warehouse manager’s fallible memory to track every order status and inventory movement in the business.

Unsurprisingly, customers rarely received goods on time and stockouts became a daily occurrence—all because we didn’t have a good WMS in place.

By improving efficiency and data sharing, a warehouse management system can help you fulfill two of today’s shoppers’ biggest demands: a seamless omnichannel shopping experience and shorter lead times.

Let’s explore the six key benefits of warehouse management systems.

Achieve greater warehouse efficiency

01

Warehouse management systems automate critical warehousing processes, reducing the time required to complete them and your reliance on human labor. This means orders get fulfilled faster and less time is spent traveling around your warehouse or distribution center.

As a result, warehouse efficiency goes up and operational costs decline.

Optimize inventory management

02

Many WMS systems include robust features for improving warehouse inventory management.

Real-time inventory tracking gives you access to live, accurate information about the status of your available inventory, and automated inventory reporting tells you the value of your stock on hand, which workflows are limiting productivity, and which products are your fast- and slow-movers.

These features enable you to optimize your inventory management strategy based on reliable data while reducing the risk of overordering or understocking.

Reduce operational costs

03

Despite some warehouse management system providers offering free subscription plans, most warehouse management software includes a monthly fee—typically around $300–400 per month.

But even with that cost, warehouse management systems can save you money by improving your productivity and decreasing your rate of errors. Less time is spent performing manual tasks, the cost of resolving stockouts and shrinkage events plummets, and your staff can fulfill more orders in a day.

Minimize waste and risk of human error

04

The less waste or downtime in your warehouse, the higher your productivity. This includes amending mistakes caused by humans miscounting stock or putting goods away in the wrong location.

WMS systems reduce the need for human intervention, ensuring greater accuracy in your warehousing processes.

More effective labor management

05

A WMS functions as the single source of truth in your business by sharing data between various warehousing activities—not just order fulfillment and stock statuses.

Some WMS solutions can also track employee workloads and skill levels to optimize how tasks are assigned each day. This helps you optimize labor management and monitor employee performance over time.

Improve customer satisfaction

06

With a good WMS in place, orders are picked and delivered faster. Your order accuracy will also increase, meaning fewer customer returns and more positive reviews for your brand.

When your warehouse is more efficient, customers reap the rewards, which means your business benefits, too.

What does a WMS do?

A WMS tracks and oversees the workflows that underpin your warehouse operations. It fosters a best-practice approach to warehouse management by ensuring all tasks are completed faster and with fewer errors.

When I worked for Whiteley Allcare, a physiotherapy and medical goods distributor, we used a (now-discontinued) warehouse management system called DEAR for practically everything. DEAR told me which items needed restocking, which customer orders to fulfill each day, and when to expect backordered goods. It made my job significantly easier and allowed the business to satisfy customer expectations while keeping operational costs low.

In a business using a reliable WMS, the warehouse management process looks like this:

- Data sharing.

Sales and inventory data is automatically collected as orders come in, inventory statuses change, or purchase orders are raised. - Creation of fulfillment tasks.

The WMS informs warehouse teams when to pick orders, what to pick, and where to find the required inventory. - Creation of inventory management tasks.

The system also identifies the optimal time to reorder inventory, fulfill backorders, and relocate stock. - Labor assignment.

Warehouse tasks can be automatically assigned to specific workers based on existing workloads, skill levels, and roles. - Automation of manual processes.

WMS software improves the efficiency with which warehousing activities are performed by automating repetitive manual tasks such as data entry and stocktaking. - Updating records and streamlining workflows.

When tasks are completed and updated in the WMS, a change in status triggers the assignment of the next task. For example, the task of fulfilling customer backorders can be automatically assigned as soon as the backordered inventory is receipted into the system. - Strategic planning.

Cloud-based WMS systems track warehouse performance and generate reports that allow you to make data-driven decisions around business strategy, marketing, and purchasing.

NOTE: With a projected compound annual growth rate (CAGR) of 16.23% for 2024–2032, the increasing adoption of warehouse management systems is largely driven by evolving consumer needs—and the businesses scrambling to meet them.

Warehouse management system functions

Warehouse management systems vary greatly in functionality and complexity.

I’ve used WMS solutions that could do little more than print shipping labels and scan barcodes, and comprehensive ERP software with WMS functionality that managed everything from our accounting and payroll processes to inventory management and order fulfillment.

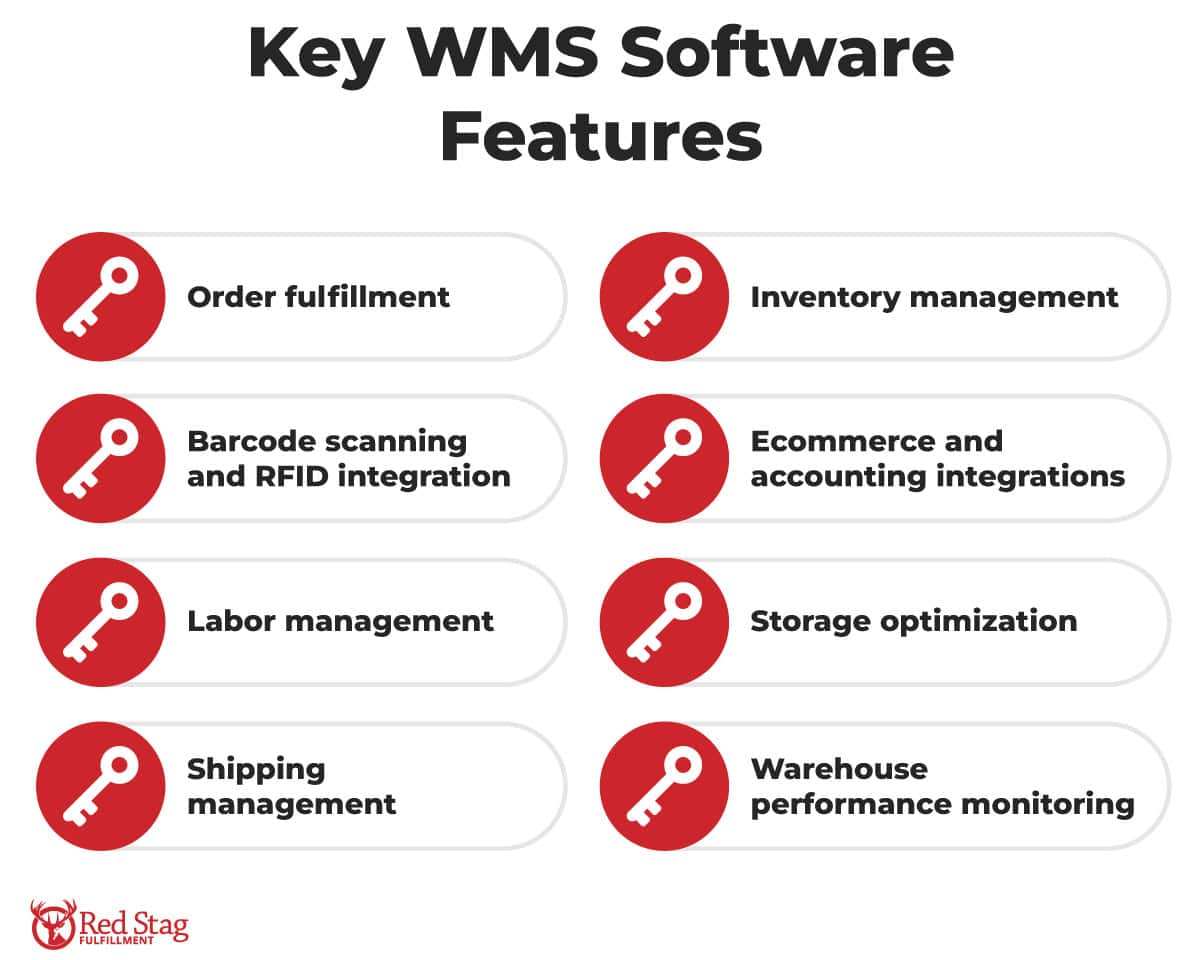

If you want a well-rounded WMS, here are some crucial features to look for:

Order fulfillment

Inventory management

Barcode scanning and RFID integration

Ecommerce and accounting integrations

Labor management

Storage optimization

Shipping management

Warehouse performance monitoring

PRO TIP: The diversity of WMS applications highlights the importance of choosing the right system for your specific needs. If you’re in the market for a new system, be sure to make a list of your requirements and choose a solution that’s best equipped to achieve the outcomes you desire.

Order fulfillment

Warehouse management systems improve the speed and accuracy of order fulfillment processes by automating tasks like order picking, order status updates, and shipping management. This ensures customers receive the right products and orders are delivered on time to meet demand.

Inventory management

Cloud-based WMS solutions give you real-time visibility into on-hand inventory levels, minimizing the need for regular manual stock checks. They enable you to track inventory items across different locations and optimize inventory purchasing to reduce stockouts and overstocking events.

Barcode scanning and RFID integration

By integrating barcode scanning or RFID technology with your warehouse management system, you can automate inventory tracking and fulfillment processes while improving the accuracy of your workflows. This helps boost warehouse efficiency while radically reducing your risk of errors.

Ecommerce and accounting integrations

An integrated warehouse management system connects with your existing ecommerce sales channels and accounting software to ensure data is consistent and accurate across the business.

How does it work?

Sales orders from your ecommerce store are picked up by the WMS and translated into fulfillment tasks to reduce manual data entry. Meanwhile, inventory and purchasing information is passed on from the WMS to your accounting software in real time for faster reconciliation.

Labor management

A WMS can improve labor management and optimize workforce productivity by automatically assigning tasks based on workload and competency, monitoring employee performance, and identifying critical areas for improvement.

Storage optimization

Some warehouse management systems enable you to optimize storage utilization by analyzing your available warehouse space. The WMS will recommend where specific items should be stored to maximize accessibility and minimize handling time based on product size, weight, and turnover.

Shipping management

A WMS helps you manage customer shipments more efficiently by automating key shipping processes and synchronizing shipping information with your sales channels and carriers. You can use it to print shipping labels, track carrier information, book collections, and ensure the best shipping method is used for each shipment.

Warehouse performance monitoring

Good warehouse management systems offer detailed reporting and analytics for tracking warehouse performance. This allows you to find inefficiencies that need addressing and make the right decisions for your business based on key metrics like order accuracy, labor efficiency, and inventory turnover.

Types of warehouse management systems

Warehouse management systems can be broadly classified into two main categories: manual and automated.

So, what’s the difference?

| Type of WMS | Manual | Automated |

|---|---|---|

| Definition | A traditional approach to warehouse management that relies on manual data entry, spreadsheets, and paperwork to manage labor, inventory, and fulfillment. | A digital system that automates manual processes and functions as the single source of truth in your business by sharing data between various warehousing activities. |

| Pros |

|

|

| Cons |

|

|

Whenever I applied for a new role during my days as a warehouse manager, there’s one question I always asked the hiring company: What systems do you currently use to manage your warehouse?

I wanted to be sure I would be working for a company that already used an automated warehouse management system. I’d learned my lesson from previous jobs—manual WMS systems make it intolerably difficult to deliver the most value to the business as a warehouse manager. I’d rather work somewhere I know I can do the job the way it needs to be done.

Automated warehouse management systems

When is the right time to invest in an automated warehouse management system?

The answer depends on your business model and your budget. However, there are some warning signs that your manual system may be doing more harm than good.

Key indicators that it’s time to upgrade your WMS:

Inventory discrepancies are sapping your working capital

You’re having difficulties reconciling stocktakes

You’re struggling to fulfill orders fast enough to meet customer demand

You lack sufficient inventory visibility to make important decisions

Overstocking and stockout events are becoming too frequent

You’re managing high volumes of customer orders

If these problems sound familiar, it might be time to invest in an automated WMS.

Different types of automated warehouse management systems include:

Cloud warehouse management system

RFID warehouse management system

Warehouse labor management system

Barcode warehouse management system

Warehouse inventory management system

Enterprise resource planning (ERP) system

There are also industry- or solution-specific types of WMS systems. For example, software designed specifically for the pharmaceutical industry. Consider any unique requirements for your business before investing in new warehouse management technology.

How much does a warehouse management system cost?

I performed an in-depth analysis of pricing for 20 of the top warehouse management systems currently on the market—as rated by real users on the trusted software review platform Capterra. Based on my analysis, the average subscription cost for a WMS system is USD 321.27 per month.

Monthly subscription fees for warehouse management systems range from $0–40,000+.

This doesn’t account for hidden costs you’ll need to consider, such as implementation, customer support, and employee training costs.

This wide variance in WMS software pricing can be attributed to a broad spectrum of functionality across different systems. Free software—for example, Zoho Inventory—will typically offer fewer features than a more comprehensive ERP solution, such as Oracle Cloud Enterprise or SAP Business One.

Best practices for WMS implementation

Implementing a new WMS can be time-consuming, dangerous (from a business performance perspective), and expensive.

I’ve seen first-hand what a poorly planned WMS implementation can do to a business.

At one company, tasks weren’t delegated and a wall-to-wall stock wasn’t performed until the day of the implementation. Hours were wasted figuring out who’s doing what, and we weren’t able to use the system until the following week. Meanwhile, the business was brought to a halt and dozens of customer orders got delayed.

To minimize risk and keep costs down, let’s cover some basic best practices for WMS implementation:

Involve key stakeholders

01

Key stakeholders are anyone in your organization impacted by or involved in warehouse operations. They include warehouse managers and order pickers, as well as your finance department and your suppliers.

Get all stakeholders involved early on in the implementation process to ensure a seamless transition. Encourage input from different teams and leverage their unique expertise when making strategic decisions around implementing your WMS.

Create a plan and set clear goals

02

Define the outcomes you want to achieve with the implementation process and create a clear plan for ensuring they happen.

This will ensure nothing important gets overlooked or forgotten.

Outline specific goals, timelines, and resources you’ll need, assign responsibilities to different stakeholders, and create a system for tracking how well it’s going.

Prepare the necessary data

03

A WMS can only do its job when it has the data it needs to do it. You’ll need to record key information about your warehouse and its inventory and input it into your system before you can start using it.

This can mean:

Counting and recording on-hand inventory levels for every item in your warehouse

Assigning product codes, bin locations, and values to your inventory

Uploading supplier information and historical sales data

PRO TIP: Your WMS is only as good as its data—make sure the information you give it is accurate and up-to-date to prevent delays and operational challenges.

Establish a testing period

04

During the early stages, test and monitor how the WMS performs when using it for various tasks. Keep an eye out for any potential bugs, workflow challenges, or technical issues.

It can be a good idea to test the software on a small portion of your warehouse or replace old processes one at a time to spot any potential problems before they have a major impact on your operations.

Change management

05

Implementing a WMS will radically change how your staff do their jobs.

To ensure a smooth transition to different ways of working, build a change management plan that helps employees adapt to any new processes.

Things to consider include:

Managing staff expectations

Involving employees in the implementation process

Communicating how job roles will change

Offering guidance on how best to use the WMS

Encouraging staff feedback

Provide thorough staff training

06

To get the most out of your WMS, make sure your staff receive all the training they need to understand how it impacts their role.

Businesses that implement a new WMS and leave their employees to ‘figure it out on their own’ are asking for trouble. It’s unlikely they’ll be using the software in the most productive way, and they’ll be more likely to make mistakes that could cost the business.

Provide comprehensive training that covers functionality, troubleshooting, and the application of your new WMS as it pertains to specific warehouse processes.

Monitor performance

07

Once the WMS has been deployed, it’s vital that you continually track performance to ensure it’s delivering the outcomes you want from it.

Track KPIs like order accuracy, order fulfillment time, and inventory accuracy to identify areas for improvement. If these metrics aren’t satisfying your goals, speak to your WMS provider to see if there are ways you could use the software more efficiently.

Warehouse management system FAQs

How does a WMS work?

A WMS is a software tool that helps businesses manage warehouse operations tasks by streamlining inventory management, synchronizing critical warehouse data, and balancing labor with workloads and skill levels. It uses cloud technology to provide real-time tracking and insights into stock levels and order fulfillment statuses while automating manual processes.

How do you choose a warehouse management system?

To choose the right warehouse management system for your business, you need to:

Understand your needs and consider your budget

Speak to stakeholders within the business

Ask for advice from a business advisor or accountant

Research WMS providers and solutions

Create a shortlist of solutions that meet your requirements

Read online reviews for different software providers

Watch a WMS software demo or take a free trial

Is WMS an ERP system?

WMS and ERP systems are different software programs that help companies manage the operations and administration of their businesses.

ERP systems are comprehensive business management solutions. While some ERP software includes warehouse management functionality, they can also come equipped with features for managing HR, accounting, customer relationship management, and procurement.

Whereas WMS systems are dedicated warehousing software specifically designed to manage and optimize operations within a warehouse setting.

Who uses a WMS?

Warehouse management systems are used by a wide range of organizations and employees. They’re commonly used in industries such as Distribution, Ecommerce, Third-party Logistics, and Pharmaceuticals.

In an average day, a WMS may be used by:

A warehouse manager, for assigning labor tasks and managing inventory

A purchasing manager, for identifying procurement needs

A finance manager, for determining inventory value and cash flow

A supply chain manager, for tracking supplier performance and lead times

A warehouse worker, for understanding order fulfillment responsibilities

Is WMS a CRM?

WMS and CRM are both business software programs, but they serve a different purpose. A WMS is for managing daily warehouse operations. Whereas a CRM helps businesses manage interactions with customers and track important customer and sales information.

Struggling with your warehouse management? Red Stag Fulfillment can help

If you don’t have the time, warehouse space, staff, or experience to efficiently manage order fulfillment and stock, consider outsourcing your order management to the experts.

Red Stag Fulfillment brings decades of warehouse management experience together with best-in-class warehousing processes to ensure your customers get what they need when they need it.

Reach out to us today to learn how partnering with Red Stag Fulfillment can help your business thrive.