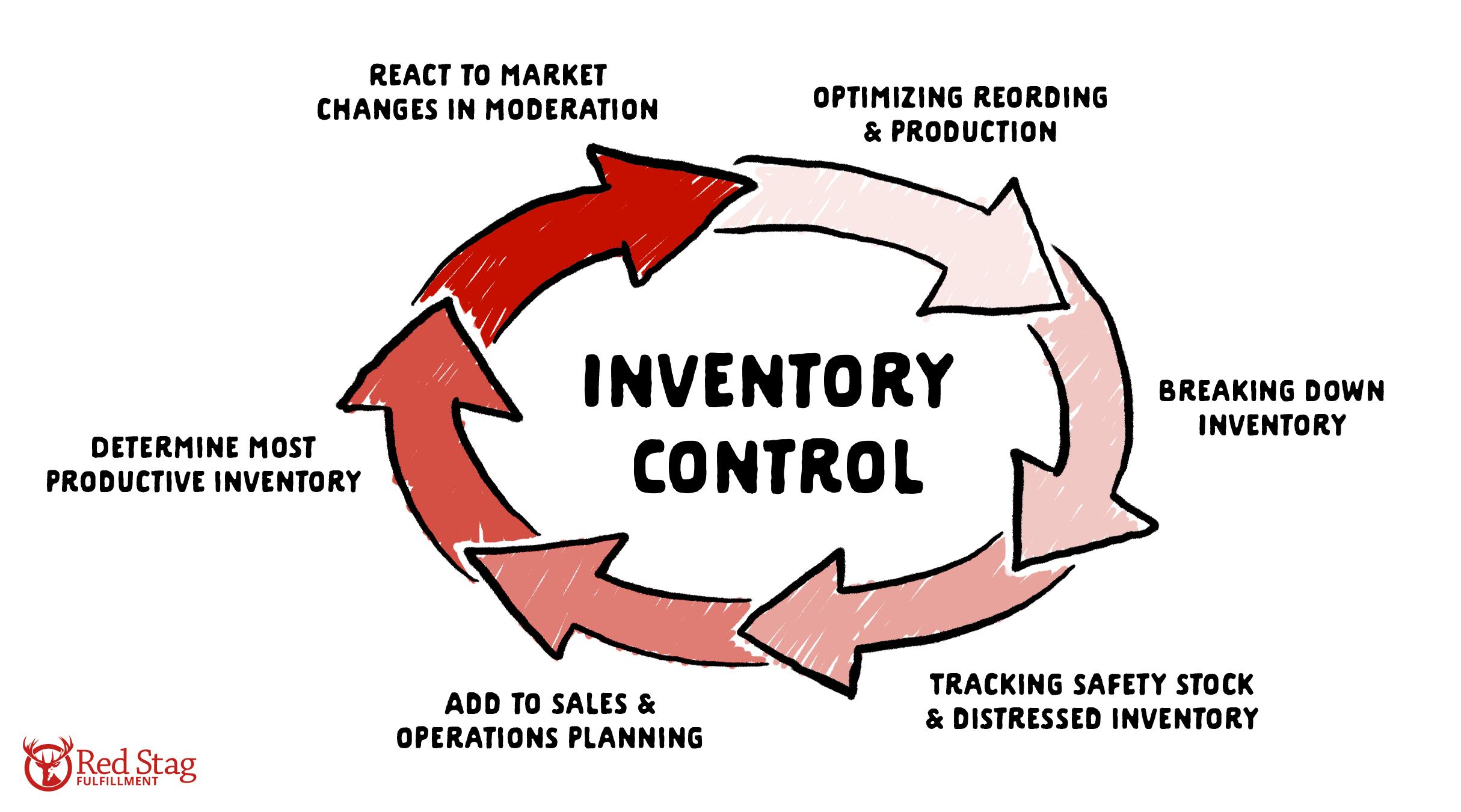

If you don’t measure and verify inventory—or use your inventory properly—you might place your company’s health at risk. That’s because, a poor understanding your inventory can make it harder to avoid stock outs and could cause you to waste resources on products that never sell. An inventory control system allows you to tackle these concerns.

What is inventory control?

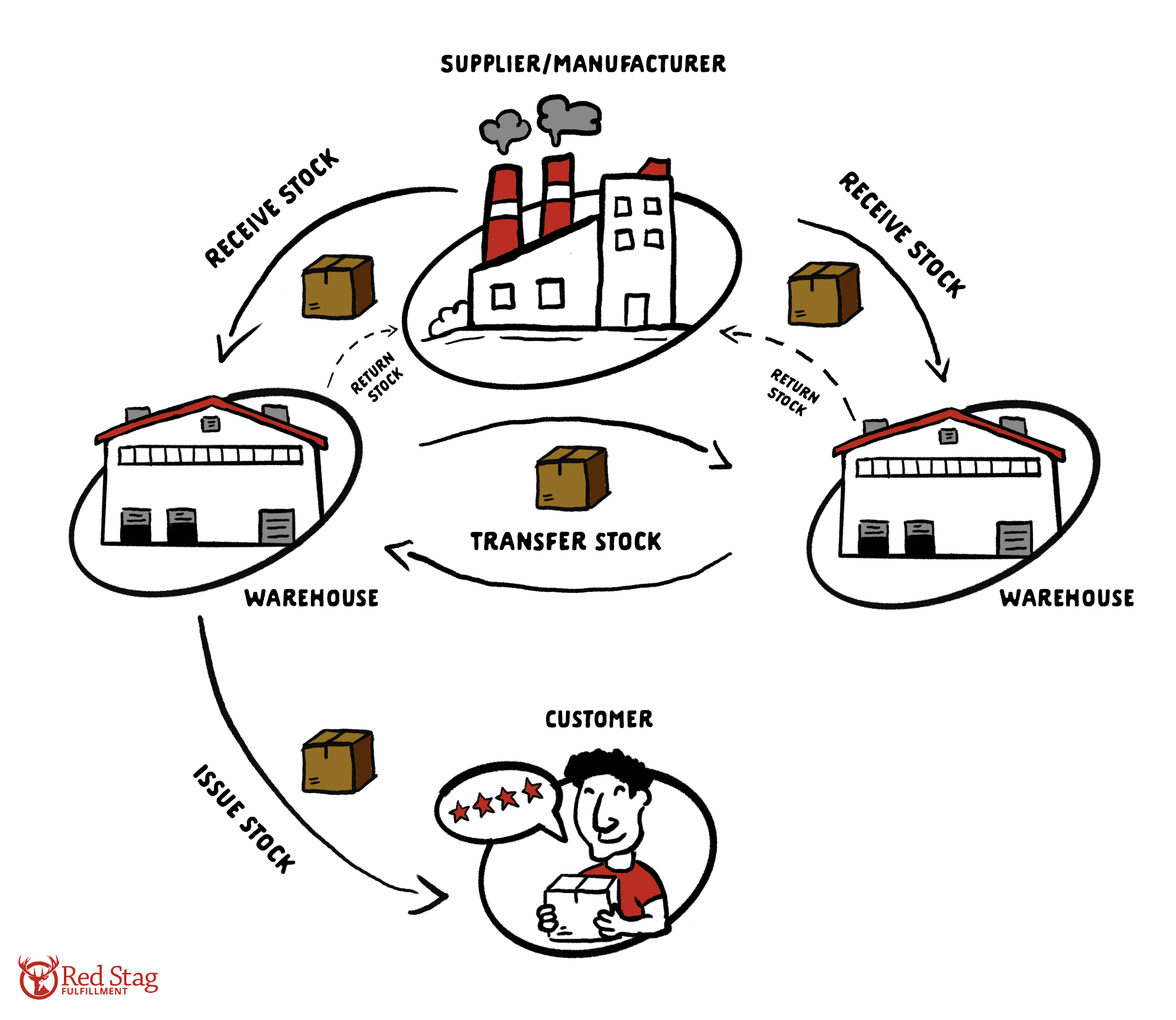

Inventory control (also called stock control) is the process of maintaining product stock levels so you can always meet customer demand quickly while keeping your holding costs low. In other words, it helps you understand what you have, where it is, and when it’s time to order more.

Inventory control aims to minimize storage, labor, packaging, and restocking costs to keep margins and customer satisfaction high. Putting an inventory management system in place can reduce those costs.

Standard features and activities of inventory control include:

-

Setting up your warehouse management system (WMS) and its inventory modules or features.

-

Integrating barcode scanners or radio frequency identification (RFID) options with your WMS.

-

Adding smartphones and apps to inventory systems for pickers.

-

Detailing the steps your team takes to create an inventory list and count.

-

Establishing minimum stock levels and reorder points.

-

Instating tracking and management for creating kits and bundles.

Why is inventory control important?

Getting inventory control right means having the proper amount of product to fill orders without needing a bunch of costly safety stock (also known as control inventory). That way, you can keep your cash flow healthy and have more capital available for investing in other areas of your business.

Inventory control also provides insights into the popularity of different items, so you’ll know when to reorder and can consider developing other similar products.

You’ll also be tracking inventory data to learn if products generate enough revenue for your business or if you should reallocate your capital investments.

Inventory control plays a part in your overall warehouse management, too. It puts checks in place so you can avoid shrinkage, mis-picks, and spoilage.

What inventory control methods do companies use?

Your inventory control tools and methods may change over time, depending on your needs and situation. It can help to know what your options are so you can evolve your inventory control systems as you grow. Take a look at some of the most common inventory control systems below.

Ledger books

For small ecom companies, you might be able to get by with a pen-and-paper ledger or stock book as your inventory control system. That can be enough if you have just a few products and can quickly count your inventory.

A periodic inventory system is pretty typical in these situations. This is where stock is counted at regular intervals and compared with sales numbers to make sure there are no discrepancies. So long as your SKU count is low and the count can be performed without hindering your order fulfillment, this can be a good option for some businesses.

However, this type of manual stock control is prone to errors. You can easily count inventory incorrectly or lose track of what’s going in and out. And if mistakes aren’t caught immediately, they can compound over time, skewing the numbers until it’s corrected.

Stock cards

Stock cards track the inventory level of a product, its unit price, and the value of your entire stock. Whenever an item is removed or added to your total inventory, someone should update the card.

They’re called stock cards because they used to be physical cards with handwritten updates and notations. Now, they’re mostly digital in software programs like Excel.

Sales and fulfillment aren’t the only times when updates are necessary. It’s important also account for lost or damaged items and product that’s used for sales or marketing purposes.

Spreadsheets

Sophisticated spreadsheets (e.g., Excel) can track a wide range of data points, from stock-keeping units (SKUs) and barcodes to quantities, costs, and reorder levels. Various software features can make it easy to do things like create alerts when inventory drops below a certain level so you can reorder in time to avoid stocking out.

Barcode scanners often come with software that auto-populates information into Excel spreadsheets. You can import the most recent information through the Excel “Data” section, making sure that you have up-to-date numbers at your fingertips.

The downside is that updates are typically only made after the end of a shift. That delay can allow fulfillment mistakes to go unnoticed until orders are already out the door.

It’s also important to note that Excel isn’t inventory management software. It’s a great tool, but it can only do so much. If you need real-time insights, a perpetual inventory control system might make more sense for you.

Starter stock software

Basic stock control and inventory management software typically includes a broad range of features that coordinate with your retail platforms, along with barcode scanners and point-of-sale tools. There’s usually some level of implementation support that’s needed to get the system up and running.

Shifting to dedicated inventory management software brings the benefits of automation and improved accuracy. By integrating with your tools and other platforms, your inventory control system delivers real-time data and automatic updates. Many tools also provide immediate notifications so you can reorder stock during business hours, avoiding the need to wait until the next day to place your order.

Advanced functionality can also help you identify product turnover rates, making it easier to calculate how much you spend on storing each SKU or tracking losses related to shrinkage or expiration. That way, you can generate reports on the actual revenue and margins from each SKU and identify the best- and worst-performing inventory. You can also calculate safety stock with greater accuracy.

Integrated software and partners

One of the final evolutions of inventory control systems is an advanced warehouse management system (WMS) or enterprise resource planning system (ERP). These systems integrate with your other tools and platforms, bringing the data from all sources together with powerful tools and automation to improve your inventory control techniques and scaling to meet the demands of working within the global supply chain.

Large systems not only integrate with your other tools, like an ecommerce sales platform, but they bring together data from multiple sources to improve your inventory management efforts.

At this level, an inventory control system can make suggestions for how to layout your warehouse to enhance pick-and-pack efforts. You can use historical data for demand forecasting and inventory planning analytics.

The software can help you buy the proper control inventory amounts to avoid stockouts while minimizing your storage costs. It can work across multiple warehouses and even help you route orders to the correct location to use existing inventory while minimizing shipping and fulfillment costs.

If you’re thinking about using a WMS for a perpetual inventory system, it might be a good idea to outsource your fulfillment to a 3PL. A vendor-managed inventory partner should already have this necessary technology and be able to easily integrate it with your existing sales platforms and inventory management systems.

You may even be able to see real-time data on your inventory levels and detailed analytics support to keep your business thriving. Many companies find this type of partnership much more cost-effective than scaling their fulfillment operations and owning their warehouses.

10 best practices

To help you think about inventory control, we’ve put together this list of ten best practices and policies. These inventory management best practices help you avoid some of the more significant challenges of inventory management while also providing reasonable justification for upgrading platforms or changing policies to protect your operations.

Business practices

Best practice 1: Shift to a perpetual inventory control system if you can. They’re less prone to error than a periodic inventory system and provide real-time, accurate data whenever you need it.

Best practice 2: When possible, have separate teams responsible for stocking shelves and picking orders. This helps minimize mistakes and shrinkage risks. If you’re a small organization, try to keep your administrative staff away from supply chain tasks. Your warehouse experts can handle that stuff.

Best practice 3: Audit your inventory control processes. Make sure data moves freely between systems and remains accurate. On occasion, manually verify your inventory to make sure the software is capturing stock levels accurately, and you haven’t overlooked any shrinkage.

Warehouse processes

Best practice 4: Institute multiple scanning checkpoints. For example, scan products when they’re first received, placed on the rack, when they’re picked for an order, when they’re packed for delivery, and before they’re given to the carrier for delivery. This helps eliminate manual errors and keep inventory numbers accurate.

Best practice 5: Train your team on inventory management procedures. Staff members need to learn how to safely store goods, use the correct inventory to fill an order, and record stock movements in your inventory control system.

Best practice 6: Create clear processes for tracking physical inventory from the moment you receive product in your inventory to when you ship items for delivery. Making sure everyone completes each step accurately can go a long way to keeping your warehouse management efficient.

Best practice 7: Don’t neglect the equipment you need for inventory control. Have backups for frequently used instruments such as scanners, perform frequent maintenance on them, and upgrade ahead of obsolescence.

Software practices

Best practice 8: Regularly review your stock levels and orders within the inventory control software. That will help keep your data accurate and reorder stock at the appropriate times. Business decisions are easier to make when you know exactly how much inventory your have (including safety stock).

Best practice 9: Create and manage SKUs within your inventory control software. And be sure to pay special attention to this when you create kits. That’s because kits need their own SKUs, and you’ll need to properly reduce other inventory levels as you build and scan in each kit.

Best practice 10: When you add new products to your ecommerce store, fill in all product details in your inventory control tools. This step helps you better track what you’re selling so you can get a clear picture of what your customers like and want more of—all within your inventory management software.

What if you need help with inventory control?

Inventory control is challenging, especially as you expand. You’re going to face supply chain challenges and have plenty of questions along the way. Working with a trusted third-party logistics provider like Red Stag can be a great way to dial in your inventory control process and keep your supply chain humming.

Reach out to start a conversation and discover what Red Stag can do for your business’s inventory management.