In our just-in-time, instant gratification world, no one likes out of stock notifications. However, sometimes your supply chain breaks down and an item goes out of stock. If you’re wondering what to do if a product is out of stock, there is a solution: backorders. You can keep your products available on backorder and allow your customers to keep shopping.

Backorders aren’t ideal. Consumers don’t like to wait for the products they want. ECommerce businesses don’t like the headache of managing backorder payments and shipping. If your backorder rates are high, this could signal a problem with your inventory management.

However, there are times when backorders are unavoidable. Supply chains break down. Weather or natural disasters can hold up transportation. In 2020, global manufacturing was disrupted, creating shortages and delays for many companies. Combine that with a surge in eCommerce shopping, and backorders are inevitable.

If you’re struggling to get finished products onto your 3PL warehouse shelves, you have two options. You can mark items as out of stock or you can accept backorders. There can be some big upsides to taking backorders, as long as you work with a 3PL that has the warehouse space and inventory management experience to support you.

What does backorder mean?

Backorder or back order refers to items that are out-of-stock but will be back in stock be soon.

A product on backorder is already planned by the manufacturer but has not been produced yet, and will be next on the list for delivery when it is back in stock. Customers can buy backordered items on a website, and they will be delivered as soon as they are back in stock. When a SKU is “on backorder” that means that you are pre-ordering a product that is temporarily unavailable.

Backorder vs Out of Stock

When a product is marked “out of stock” on your website, customers can’t place an order for that item. Backorders can be ordered by customers, while out-of-stock items cannot be ordered. In both cases the items are unavailable, but items on backorder are guaranteed to come back in stock and be delivered at a later date, while out-of-stock items are not guaranteed to come back. Backordered items will have a longer than normal shipping time, but they will still be delivered at a later date once the items are no longer on backorder.

The decision to mark an item backordered vs. out of stock will depend on your business model. Will customers wait for the item to be delivered? Do you have systems in place to track back orders? In your business, what does it mean to be on backorder? How do back-ordered items affect your inventory management?

Will your customers accept delayed shipping?

Backorders don’t work for every business. If consumers can readily buy similar products or alternative products from another online store, they are unlikely to wait for delayed delivery from you. If your items fill an immediate need, such as household products, customers probably can’t wait long to receive their orders.

However, back orders can work well for niche products. If your items are top of the line or unique, the wait to receive an order can even give your business an aura of exclusivity. Think of your preorders as the virtual equivalent of the lines around the block every time Supreme drops a new product.

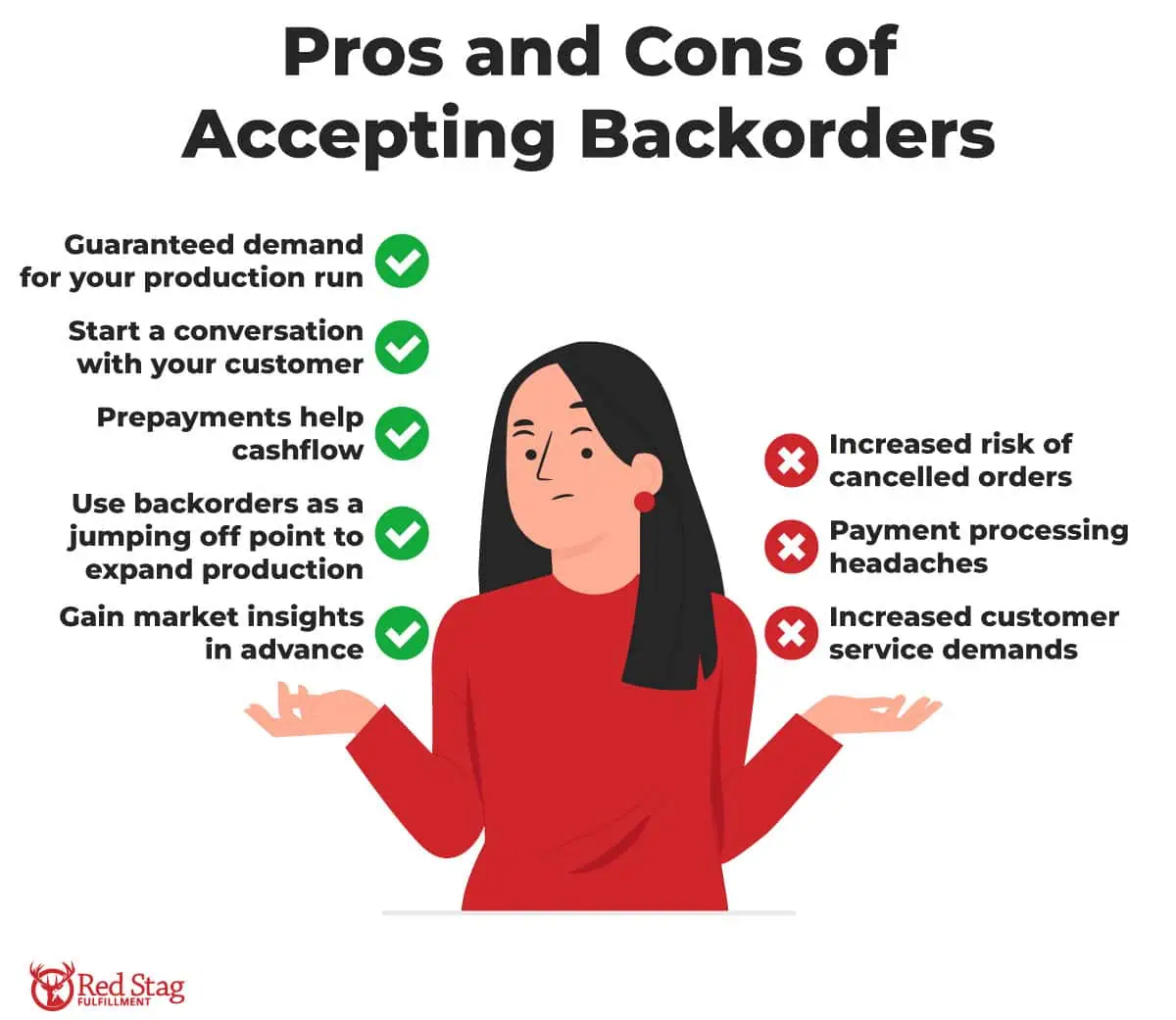

Pros and cons of accepting backorders

The entire crowdfunding business model centers around the concept of the backorder, although it isn’t called that. You pay up front for a “reward” with the understanding that you will receive it months or even years later.

Benefits of selling back ordered items

The crowdfunding model helps highlight some of the positive aspects of getting preorders for your products.

- Guaranteed demand.

This is as close as you can get to a crystal ball to predict future demand. - Customer contacts.

Once a customer places an order, you have their contact information. You can communicate with them about their current order and future offers. - Prepayment.

Crowdfunding platforms take payment up front, and businesses use that capital to ramp up production on a new product. If you process all or some of the payment to hold the backorder, this can help your cashflow through manufacturing and distribution. - Growth potential.

If some of your products are already spoken for, you can use that capital to increase your manufacturing run. This can help you hit revenue benchmarks in your business and grow your business. - Market insights.

There is no better customer survey than back orders. Customers are telling you what will be in the highest demand — including the hottest colors and sizes.

What backorders may cost your business

There are, of course, some major downsides when your customers have to wait to receive an order.

- Cancellations.

The longer someone has to wait to receive an item, the greater the chance they will change their mind. They might have second thoughts about an impulse purchase. Or their circumstances could change, so they no longer want or need the product. - Payment processing.

The credit card your customer gave at the time they placed the order might expire before you process the payment, if you wait until the order ships. When you contact them for updated payment information, it’s another chance for them to change their mind. - Customer service headaches.

The chances of issues that require customer service time to resolve increase with backorders.

Fortunately, with proper management, you can mitigate the headaches that come with backorders. Read on for tips to help you turn your backorders into a positive experience for you and your customers.

Managing backorder payments

The best practice for backorders is to process payment shortly before the order ships. However, you want to know that the payment method your customer provided is legitimate.

Online payment processors have systems to detect fraud and determine if a payment method is valid. In some cases, this may mean running a transaction of a few cents to verify a credit card. Find out if your payment processor has a system in place to confirm your customers’ payment methods.

Cross-docking: backorder fulfillment

One of the ways to reduce a backlog is to process backorders quickly once you receive the merchandise. However, it can take days for your order fulfillment warehouse to process a container full of product, log it into inventory, and place it on the shelves. Only then can the fulfillment company start processing the backorders.

Fortunately, there’s a fulfillment solution for that: cross-docking.

Cross-docking is a process where products come in at a receiving dock and go directly to the shipping dock. This skips the step of putting items on warehouse shelves.

Cross-docking requires robust systems to ensure that orders are picked, packed, and shipped correctly. To help our clients clear backorders more quickly, Red Stag Fulfillment has instituted cross-docking procedures at both our national fulfillment warehouses. The process can save fulfillment time, get revenue into your business more quickly, and reduce waiting time for your customers.

3 tips to reduce the pain of backorders for your business and your customers

There are many strategies to work with customers who are waiting for backordered items. If some items are in stock, you can ship a partial order and waive the extra shipping charges. You can offer discounts or coupons on future orders.

However, the most important thing you can do is communicate clearly and honestly. This starts with your website and continues with follow-up emails after the customer places the order. Here are three communications tips to keep your backordered customers happy.

Set expectations

Start by noting clearly on your website which items are backordered. Include the expected shipping time, if you know it. If the customer doesn’t find out about the delay until after they place the order, you’re off to a bad start.

Follow up by email. Let your customers know you are working on the problem. In addition, it’s important to let customers know when the item is about to ship. That way, they won’t be surprised when the charge appears on their credit card.

Build excitement

One of the biggest risks of a delayed order is that the customer will change their mind about the purchase. Your communications can keep cancelled orders to a minimum.

Set up an automated email funnel to send to people while they wait for their orders. Tease the qualities of the product. Introduce related products or accessories they might want to purchase. Count down the days until the product ships.

Use these emails to generate a sense of anticipation and excitement. Make the delayed order an opportunity to connect with the customer.

Stay in touch throughout the process

Update the customer on the progress of the order. Honestly report bad news and further delays. Being honest will build trust. Otherwise, the customer may begin to wonder if they are ever getting the product.

Send stock notifications so the customer can follow the progress of back-ordered products through the supply chain. Consider giving updates about the progress on the product page or social media.

Crowdfunding provides an excellent model for this. Crowdfunded products often experience production delays. This is particularly true for entrepreneurs who are figuring out their supply chain for the first time. Yet thousands of customers endure lengthy waits and delays in hopes of being the first to get an exciting new product.

Will backorders work for your business?

When you mark items as out of stock in your online store, you turn away customers who may never come back. Setting up a system for backordering allows you to keep your customers connected.

Before you offer backorders, make sure you have systems in place to handle them. Make sure your backordered customers get placed in the front of the line when products come back into stock. Work with your fulfillment company to ensure that backorders are processed swiftly. Be prepared to deal with customer service questions that might arise about the process. Have a communications plan to keep your customers informed of the status of their orders.

Dealing with fractured supply chains and production delays is a headache. But you can make the best of a bad situation by offering backorders to your customers.

Backorder FAQs

What is a backorder item?

A backorder item is an item that is out-of-stock. Backorder items will be back in stock when they are produced by the manufacturer.

What is the meaning of backordered?

When a product is “on backorder”, it means that customers are pre-ordering a product that is temporarily unavailable. Customers may buy backordered items, which are delivered when they are back in stock.

What does a Lego backorder mean?

A good example of how a large brand handles backorders is Lego. A Lego backorder means that a Lego set or Lego parts are not currently available to ship, but they can be purchased. Lego backorders won’t delay the order, and will be shipped whenever they arrive at the warehouse. Lego has a support page on how it handles backorders, and how backorders work on the Lego ecommerce website.