Selecting the right third party logistics provider (3PL) is a critical decision for any ecommerce business. A strong logistics partner accelerates business growth and enhances customer satisfaction, while a poor choice leads to lost inventory, shipping delays, unhappy customers, and eroded profits. Making the right choice involves understanding how to choose a 3PL effectively.

This guide, informed by insights from industry veterans, provides a practical framework for evaluating potential partners. We’ll move beyond surface-level comparisons to uncover the factors that truly determine success in your logistics operations, helping many businesses avoid common pitfalls and identify crucial red flags in the selection process.

Quick summary – How to choose a 3PL

Meet the Experts Guiding This Article:

- Ryan Marine: Director of Sales, Red Stag Fulfillment (Business Development)

- Tony Runyan: CCO, Red Stag Fulfillment (Client Experience)

- Joe Spisak: CEO, Fulfill.com

- Jon Blair: Founder, Free to Grow CFO (Former 8-Figure Ecomm CFO/COO)

- Donovan Sullivan: Operations Manager, NFI (Logistics & Operational Efficiency)

- Sarah K: Founder, Bare Nut Butter (Brand Owner Experience)

The Common Mistake: Why Price & Location Aren’t Enough

Many businesses prioritize quoted rates or warehouse locations when first learning how to choose a 3PL, often leading to selecting the wrong partner and facing a costly switch within the first year. Relying solely on the lowest cost can be detrimental.

The most common mistake I see in the 3PL selection process is focusing too heavily on quoted rates or the perceived benefits of a particular location. Companies get excited about attractive pricing or proximity to a certain port only to discover their new 3PL can’t properly handle their products or scale with their growth.

Tony Runyan

Chief Client Officer

Red Stag Fulfillment

Jon Blair, former COO/CFO at Guardian Bikes, learned this firsthand when attractive shipping discounts from their initial logistics provider masked deeper issues impacting their business operations.

Even though this budget 3PL had the highest discounts, stuff was not arriving on time and inventory was getting lost… those costs were racking up.

Jon Blair

Founder

Free to Grow CFO

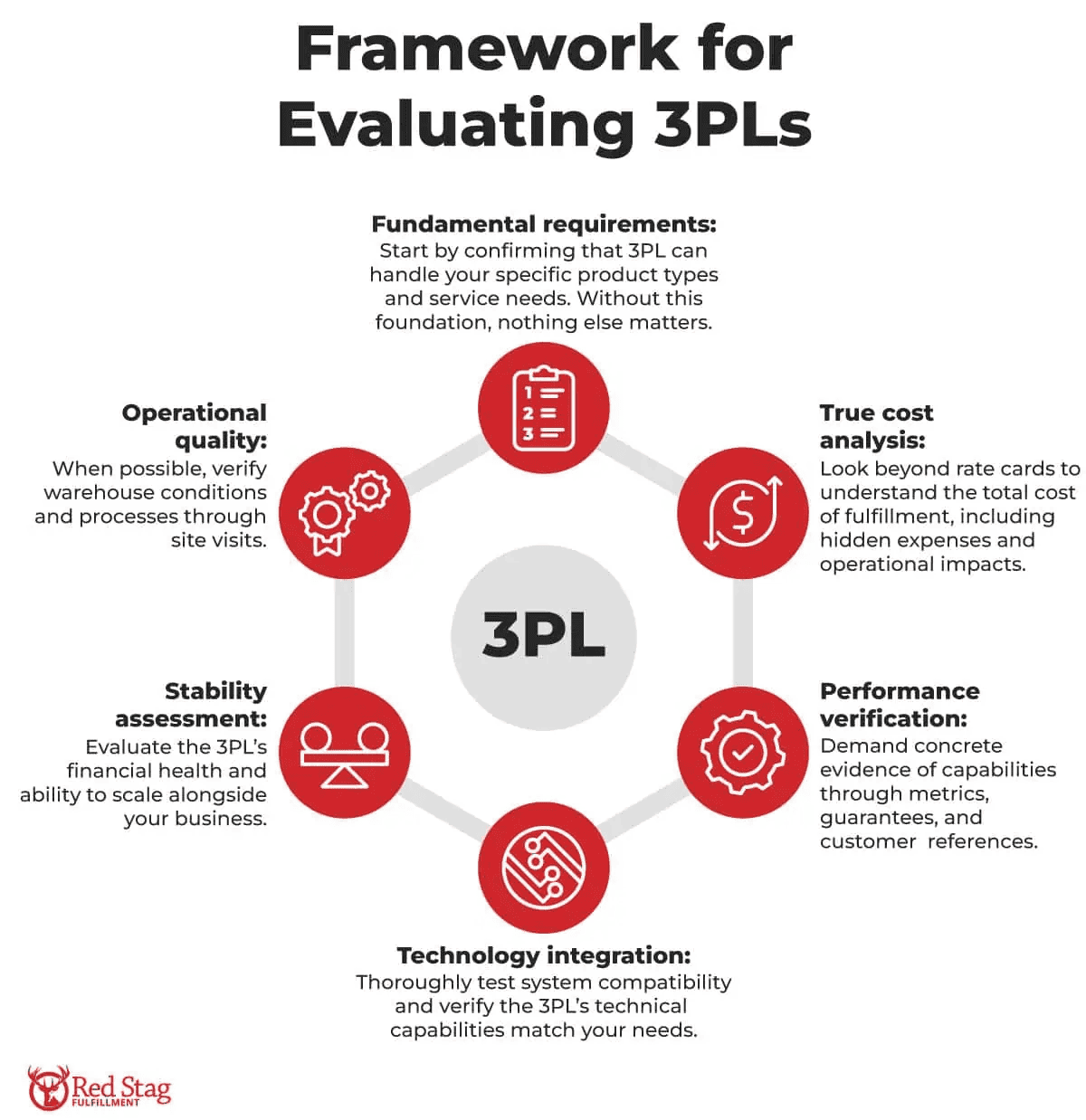

A Better Framework: 6 Critical Dimensions for Evaluation

Our experts recommend a systematic evaluation across six key areas when choosing a third party logistics company:

- Fundamental Requirements: Can the provider handle your specific products and business needs?

- True Cost Analysis: What’s the total cost of fulfillment (TCF), including hidden fees and impacts on operational efficiency?

- Performance Verification: Can they prove reliability with data and guarantees? Do they have a proven track record?

- Technology Integration: Do their systems, like inventory management software, work seamlessly with yours (e.g., your Enterprise Resource Planning system)?

- Stability & Scalability: Is the third party logistics partner financially sound and ready for your business growth?

- Operational Quality: What do their facilities, warehouse space, and processes reveal? (Verify with site visits if possible).

This systematic approach takes more time upfront, but it prevents the expensive mistakes we see when companies rush their selection process.

Tony Runyan

Chief Client Officer

Red Stag Fulfillment

Let’s explore each dimension of choosing the right third party logistics 3pl.

1. Define Your Non-Negotiable Requirements: The Foundation

Before comparing pricing structures, confirm potential partners meet your absolute basics.

The very first conversation should focus on your must-haves. I’ve seen too many brands spend precious hours evaluating a 3PL before realizing an essential component is missing.

Tony Runyan

Chief Client Officer

Red Stag Fulfillment

Create Your Checklist:

Product Specialization: Paramount. Not all third party logistics providers handle all product types effectively. A provider focused on your specific industry can be a huge advantage.

- Consider: Temperature control, fragility, size/weight (oversized/heavy items need specialized handling), hazardous materials (requiring adherence to safety regulations), certifications (food-grade, organic), lot/serial number tracking for inventory management.

- Why it matters: Generic providers may lack expertise or equipment, leading to damage, errors, or non-compliance, negating any cost savings. Proper handling impacts the entire supply chain.

‘One-size-fits-most’ 3PLs often lack specialized expertise…”Expert Insight (Jon Blair): “…Not every 3PL offers an X percent shipping discount on all products. They’ve negotiated specific discounts… based on specific attributes [like size and weight].” A 3PL specializing in apparel may struggle with bicycles.

Joe Spisak

Chief Executive Officer Fulfill.com

Required Services: Beyond basics like warehousing, what other logistics services do you need? Their core services and broader service offerings must align with your requirements.

- Examples: Custom packaging, kitting/bundling, reverse logistics (returns processing, refurbishment/disposal), subscription boxes, FBA prep, specific labeling.

Key Takeaway: Verify alignment on fundamental product handling and service needs first. If a 3PL provider can’t meet these core requirements, move on.

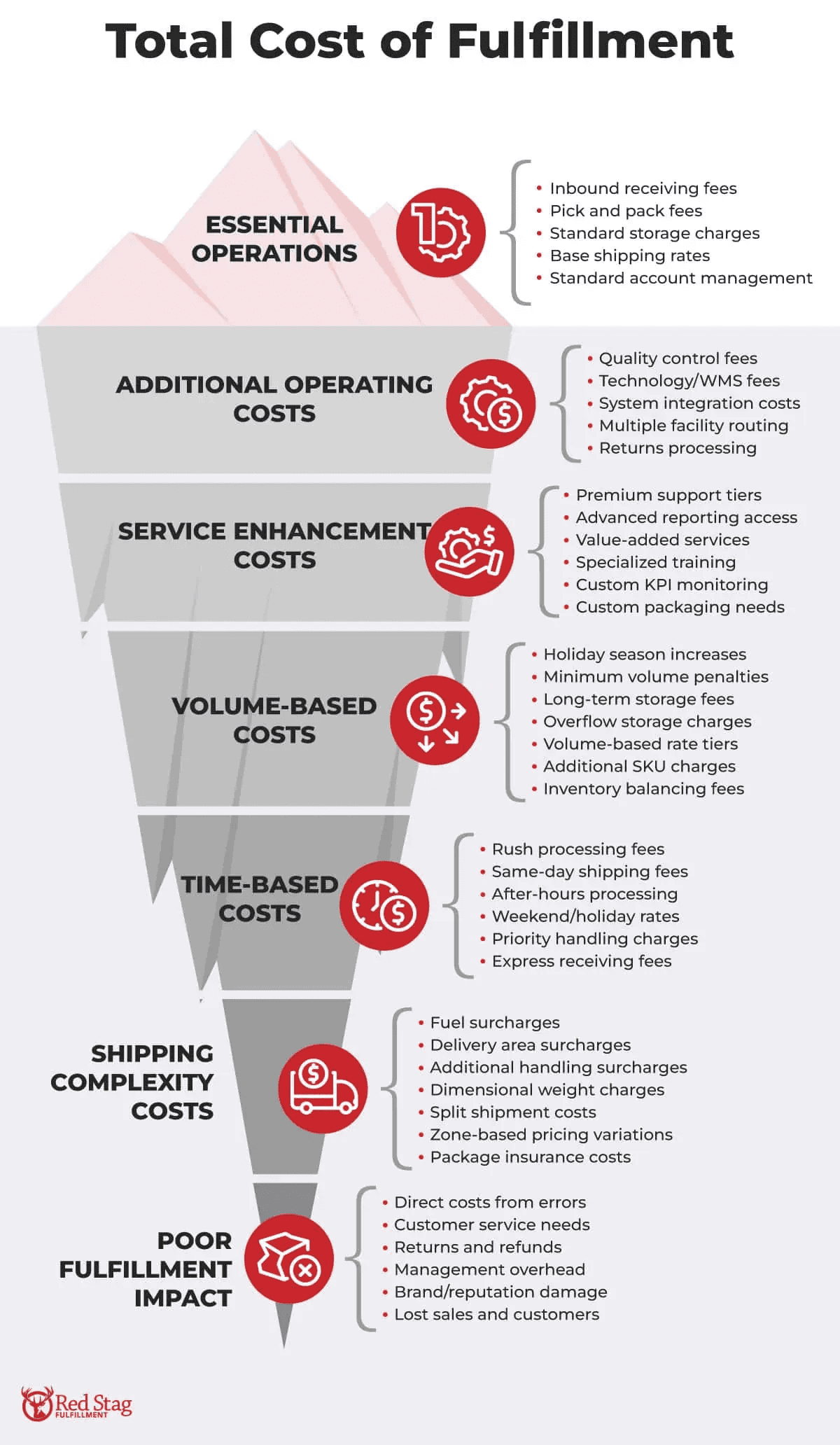

2. Calculate Your True Cost of Fulfillment (TCF): Beyond the Rate Card

The quoted price is just the starting point. Understanding the total cost of fulfillment (TCF) is crucial, as the cheapest option often hides expenses that make it more costly overall for your business.

Cheaper 3PLs may lack the scalability, technology, or customer service needed to support long-term growth.

Joe Spisak

Chief Executive Officer Fulfill.com

Understanding TCF:

TCF includes direct costs and significant indirect costs impacting your bottom line and customer experience:

- Direct Costs: Inbound receiving, storage (watch for long-term penalties), pick/pack fees, outbound shipping (carrier relationships matter here), account management fees.

- Indirect Costs (Often Overlooked):

- Cost of Errors: Replacing lost/damaged inventory, reshipping incorrect orders.

- Lost Revenue: From delays, stockouts (poor inventory management), or customers lost due to poor experiences.

- Increased Customer Service: Staff time handling fulfillment-related issues – impacts providing good customer service.

- Brand Damage: Negative reviews and reputation harm.

- Management Overhead: Your team’s time managing the 3pl partner relationship, troubleshooting, reconciling invoices.

- Inefficiencies: Costs from poor tech integration or manual workarounds impacting operational efficiency.

If your 3PL doesn’t live up to their promises, you have huge costs that don’t show up on the shipping and fulfillment expense line of your P&L.

Jon Blair

Founder

Free to Grow CFO

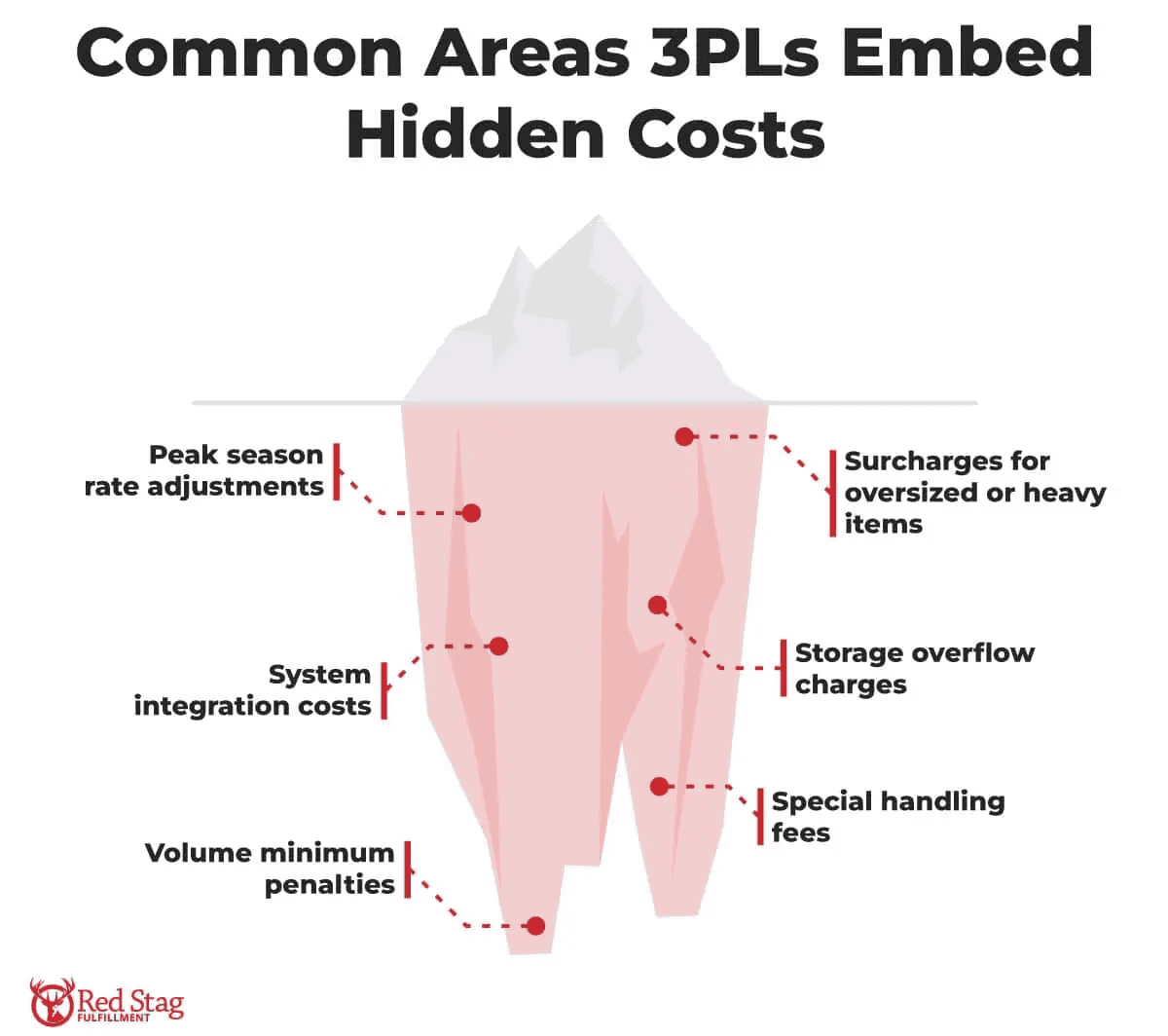

Beware of Hidden Fees & Complex Pricing:

- Common Examples: Surcharges (oversized, fuel, delivery area), peak season adjustments, minimum volume penalties, tech/integration fees, storage overflow charges, complex returns (reverse logistics) fees. These hidden fees add to the total cost.

Build a Comprehensive Cost Model:

Use your specific data, not generic examples. Ask potential third party logistics partners to model costs based on:

- Your Data: Historical shipping (3-6 months), product dimensions/weights, inventory levels/turnover, peak projections (order volume).

- Their Full Rate Structure: Include all applicable fees and surcharges in their pricing structures.

- Inbound Costs: Factor in freight based on their fulfillment centers’ locations.

- Scenarios: Model peak season impacts and future business growth.

Sit down with your prospective 3PLs and really make sure that they take your product dimensions and weights, and give you some actual pricing for what you actually ship.

Jon Blair

Founder

Free to Grow CFO

Consider Future Pricing: How might costs change as you scale (volume, locations, product lines, international)? A cheap provider now might become expensive later. Finding ways to save money long-term is key.

Key Takeaway: A thorough TCF analysis often shows a reliable, efficient 3PL with slightly higher rates is more cost-effective than a “cheaper” one plagued by errors and hidden fees. Get everything in writing before choosing your logistics partner.

3. Verify Performance Metrics & Guarantees: Demand Proof

Promises require proof and accountability. Verify the capabilities of the logistics provider and understand their performance guarantees. Look for a proven track record.

Certain performance metrics reveal whether a 3PL can actually deliver on their promises. You should examine these across multiple providers.

Donovan Sulivan

Operations Manager

NFI

Request Historical Performance Data:

Ask for concrete data (last 30-90 days & previous peak seasons) on key metrics:

- Order Accuracy: % of orders shipped correctly (aim for 99.5%+). High order accuracy is crucial.

- On-Time Shipping: % shipped within agreed timeframe.

- Inventory Accuracy: System vs. physical count alignment (key for inventory management).

- Dock-to-Stock Time: Inbound receiving speed (typically 24-72 hours).

- Order Cycle Time: Order placement to shipment duration.

- Error Resolution Timeframes: Speed of fixing issues.

Why It Matters:

Orders not going out, the wrong stuff going out… we were getting hit up by customers saying my order never arrived, the wrong thing arrived.

Jon Blair

Founder

Free to Grow CFO

Demand Guarantees & Service Level Agreements (SLAs):

Top-tier third party logistics companies offer clear SLAs with financial penalties. Ask:

- What key metrics are guaranteed (accuracy, deadlines, shrinkage)?

- What’s the compensation/penalty for missing standards (credits, paying for errors)?

- How are issues tracked, reported, and addressed?

- What reporting/visibility is provided for day to day monitoring?

Pro Tip: Hesitancy to offer concrete guarantees with financial consequences for key metrics is a major red flag.

Evaluate Quality Systems & Processes:

Understand how they achieve performance and operational efficiency:

- Quality control checkpoints (receiving, picking, packing, shipping)?

- Error prevention/detection methods (scanning, weight checks)?

- Technology supporting accuracy?

- Employee training and incentives for quality?

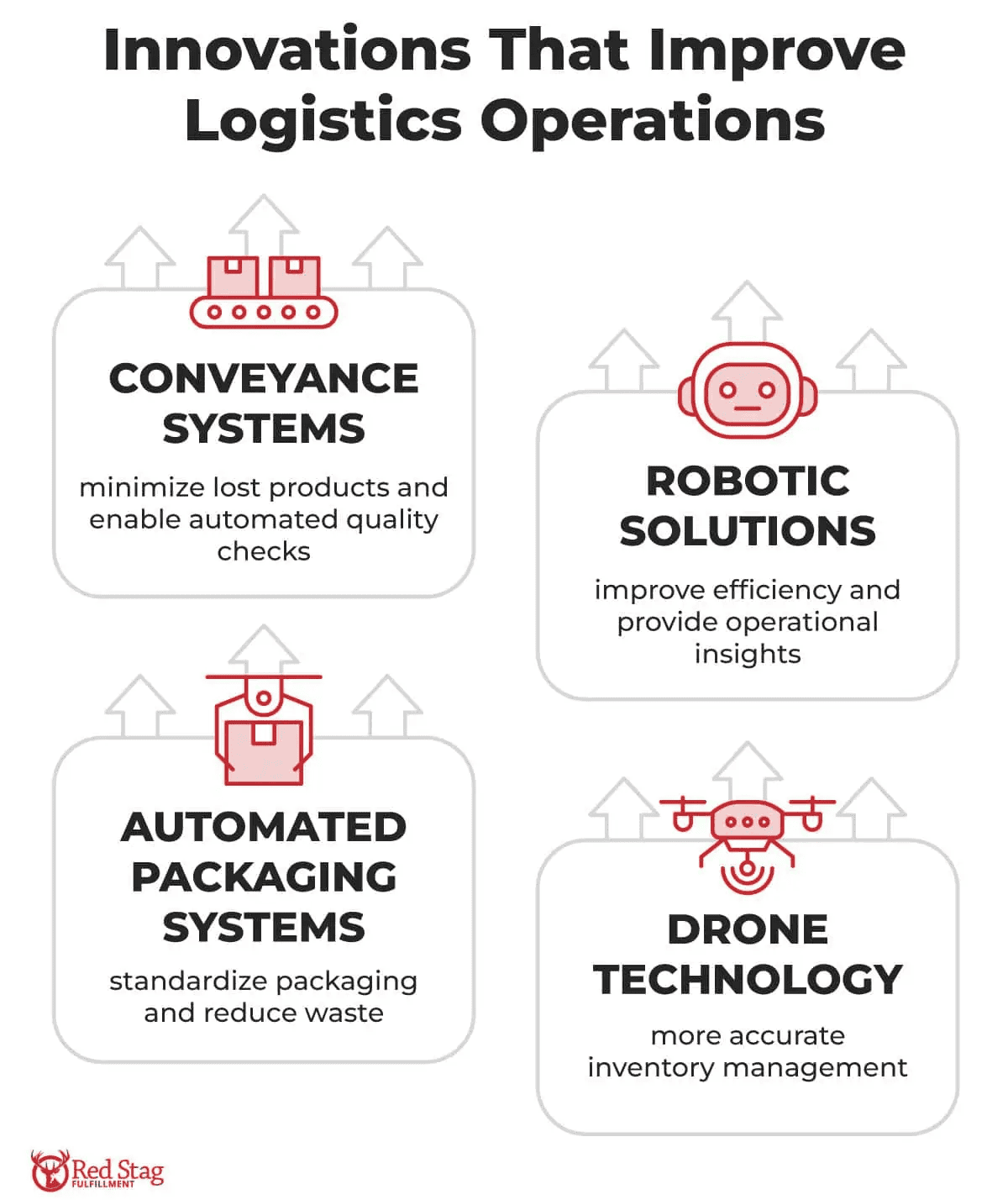

Assess Automation Realistically:

Automation (technology) can help but isn’t always the best solution, especially for large/heavy items impacting logistics operations.

When you’re dealing with big stuff, you need sophisticated processes that involve people. There aren’t many robots or automation systems that will lift a 110 lb package.

Tony Runyan

Chief Client Officer

Red Stag Fulfillment

Well-trained staff and proven processes are often more effective than complex automation for non-standard items in fulfillment services.

Key Takeaway: Demand verifiable data and robust guarantees with financial accountability. Understand their quality control processes. Don’t be swayed by promises alone when you choose a 3PL.

4. Test Technology Integration & Tools: Ensure Seamless Operations

A 3PL’s technology is crucial, but useless if it doesn’t integrate smoothly with your business systems or provide needed visibility for inventory management and order tracking.

Verify System Compatibility First:

Critical integration is between your systems (like an Enterprise Resource Planning (ERP) system, ecommerce platform) and their Warehouse Management System (WMS).

If a WMS connection “requires a lot of manual steps or workarounds, it may not be a good choice…”

Donovan Sulivan

Operations Manager

NFI

- Ask specifics: How does data flow (orders, inventory, shipping)? APIs? Pre-built integration?

- Identify manual processes: Beware frequent data exports/imports or manual entry – these cause errors and delays in business operations.

Calculate the True Integration Cost:

Consider setup fees plus:

- Your Team’s Time: Testing, validation, training, monitoring.

- Ongoing Fees: WMS access or technology fees.

- Maintenance & Updates: Factor in costs if system updates break integrations.

Demand Real-Time Visibility:

You need instant, accurate information. Ask potential partners to demonstrate how you’ll see:

- Order status?

- Inventory location and availability?

- Inbound shipment status?

If access requires downloads, reports, or contacting support, it lacks real-time visibility. Insist on seeing the actual client portal/dashboards for day to day operations.

There are a lot of 3PLs out there that are now kind of just using a pretty interface. Ask in advance for examples of inventory reporting and specific reports. If it’s not accurate, then it’s not really worth anything.

Sarah

Founder | Bare Nut Butter

Test Technology Before Committing (If Possible):

If allowed (e.g., sandbox environment):

- Process test orders.

- Simulate returns (reverse logistics).

- Verify inventory updates.

- Check reporting accuracy.

Finding issues during testing is better than post-launch.

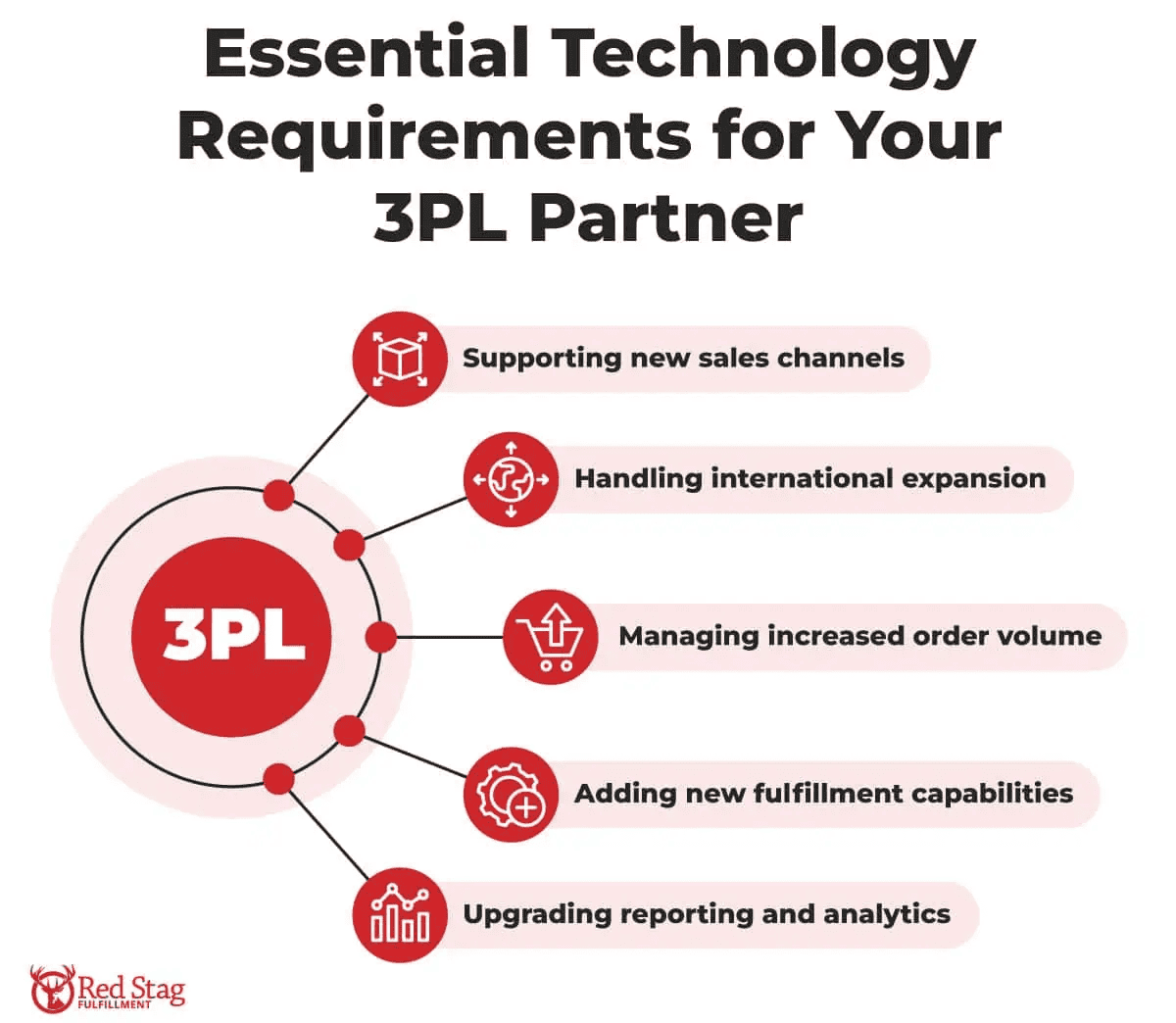

Consider Future Growth Needs:

Discuss their tech roadmap: Can their technology support new sales channels, international shipping, increased order volume, new fulfillment services, advanced analytics as your business grows?

Key Takeaway: Prioritize reliable, seamless integration and real-time visibility over flashy features. A solid basic system beats an advanced but poorly integrated one. Unclear technical explanations are a red flag.

5. Assess Stability, Scalability & Communication: The Partnership Aspect

Your 3PL provider is a critical partner. Their financial stability, ability to scale with your business growth, and communication effectiveness are vital for a successful relationship.

Verify Fundamental Business Stability:

An unstable third party logistics company risks bankruptcy, operational failures, or service cuts. Look for:

- Financial Health: Sustainable margins (beware extremely low pricing).

- Consistent Leadership: Stable management.

- Well-Maintained Facilities/Equipment: Shows investment in logistics operations.

- Reliable Workforce: Low turnover suggests good management.

- Track Record: History of weathering industry challenges; consider contingency plans.

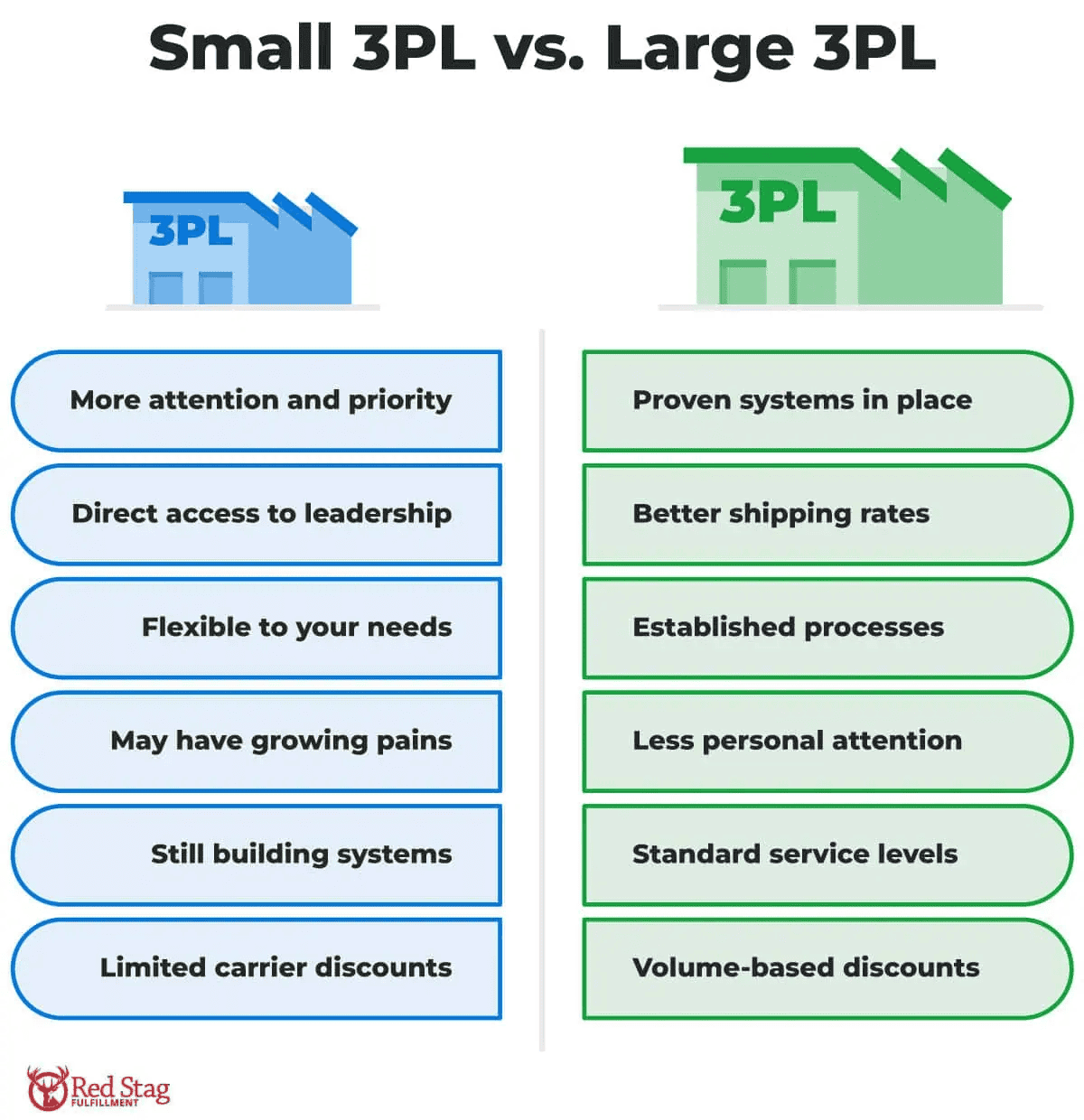

Choose the Right-Sized Provider:

Consider small vs. large 3PLs relative to your business size and demand:

- Smaller 3PLs: Pros: More attention, flexibility. Cons: Potential growing pains, fewer resources/discounts.

- Larger 3PLs: Pros: Proven systems, better rates (carrier relationships), more resources. Cons: Less personal attention, potentially bureaucratic.

“Do you want to be a big fish in a small pond, or a small fish in a big pond?” Choose based on your priorities and business needs.

Donovan Sulivan

Operations Manager

NFI

Evaluate Scalability: Can They Grow With You?

Assess their capacity to support: Increased order volume (daily/peak), more SKUs, new sales channels, returns at scale (reverse logistics).

Verify Growth Capacity Through:

- Specific Examples: Case studies/references of scaling clients.

- Clear Plans: How they handle surges? Capacity expansion plans (warehouse space, labor)?

- Peak Season Performance: Demand data from previous holidays (the ultimate stress test).

- Available Resources: Physical space? Tech capacity?

Establish a Clear Communication Framework:

Poor communication causes friction and impacts customers. Providing good customer service often relies on smooth communication with your fulfillment partner.

Every time we reached out to our old 3PL, it was some version of ‘oh, hold on, let us get back to you.’ If they even got back to us, it was like, ‘oh, you know what, man? We’re just really busy right now and really short-staffed.

Jon Blair

Founder

Free to Grow CFO

Define expectations:

- Points of Contact: Routine vs. urgent? Escalation path?

- Response Times: Agreed turnaround times (e.g., same day for urgent)?

- Reporting: Frequency, format, content?

- Proactive Communication: How are potential issues communicated?

Customers don’t don’t care that your 3PL isn’t doing their job. They just think it’s your brand.

Tony Runyan

Chief Client Officer

Red Stag Fulfillment

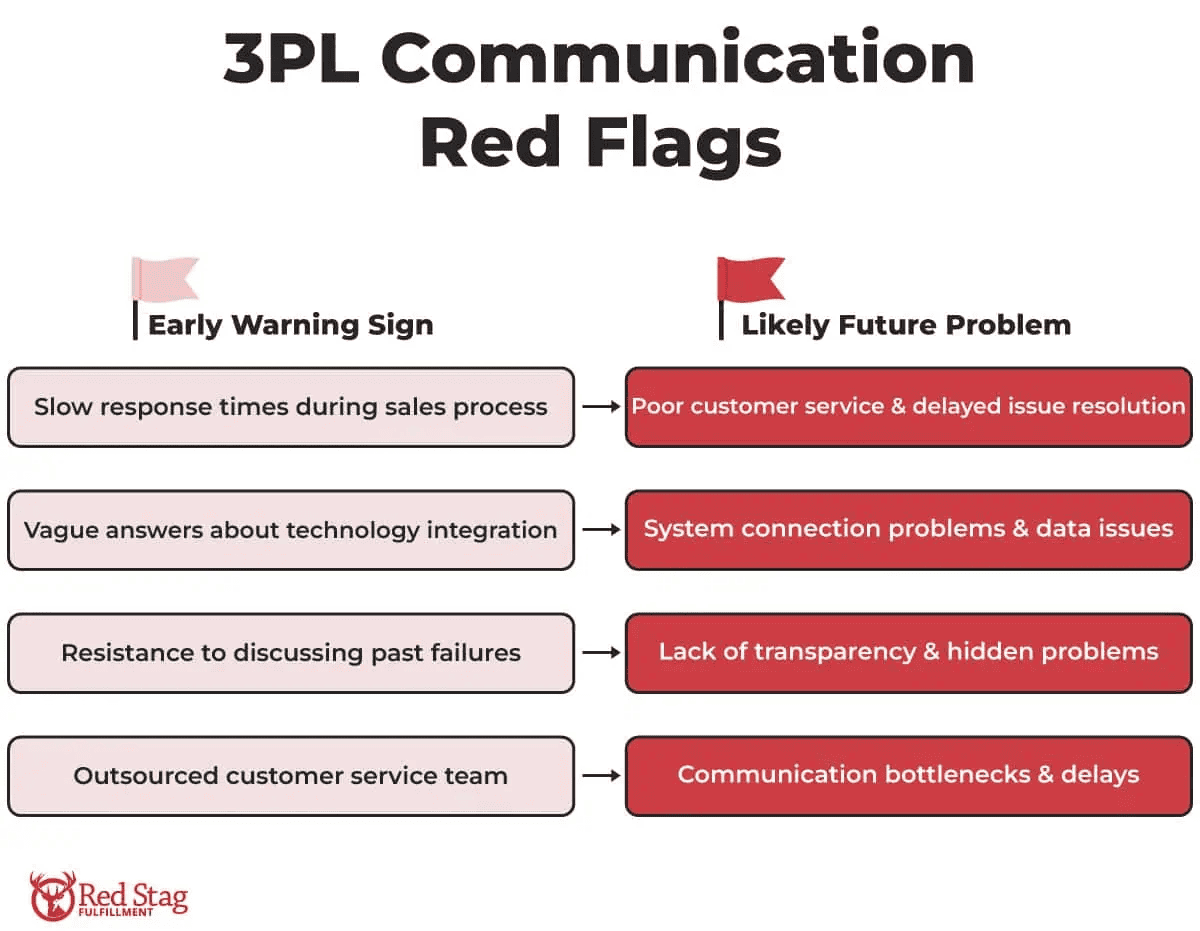

Watch for Communication Red Flags:

- Slow responses during sales.

- Vague answers on processes/contacts.

- Resistance to discussing failures.

- Outsourced/disconnected support (ask how support interacts with warehouse operations).

Key Takeaway: Choose a stable, scalable partner whose size and communication fit your needs. Define protocols clearly and heed red flags. Switching 3PLs is highly disruptive. Find a long term partner.

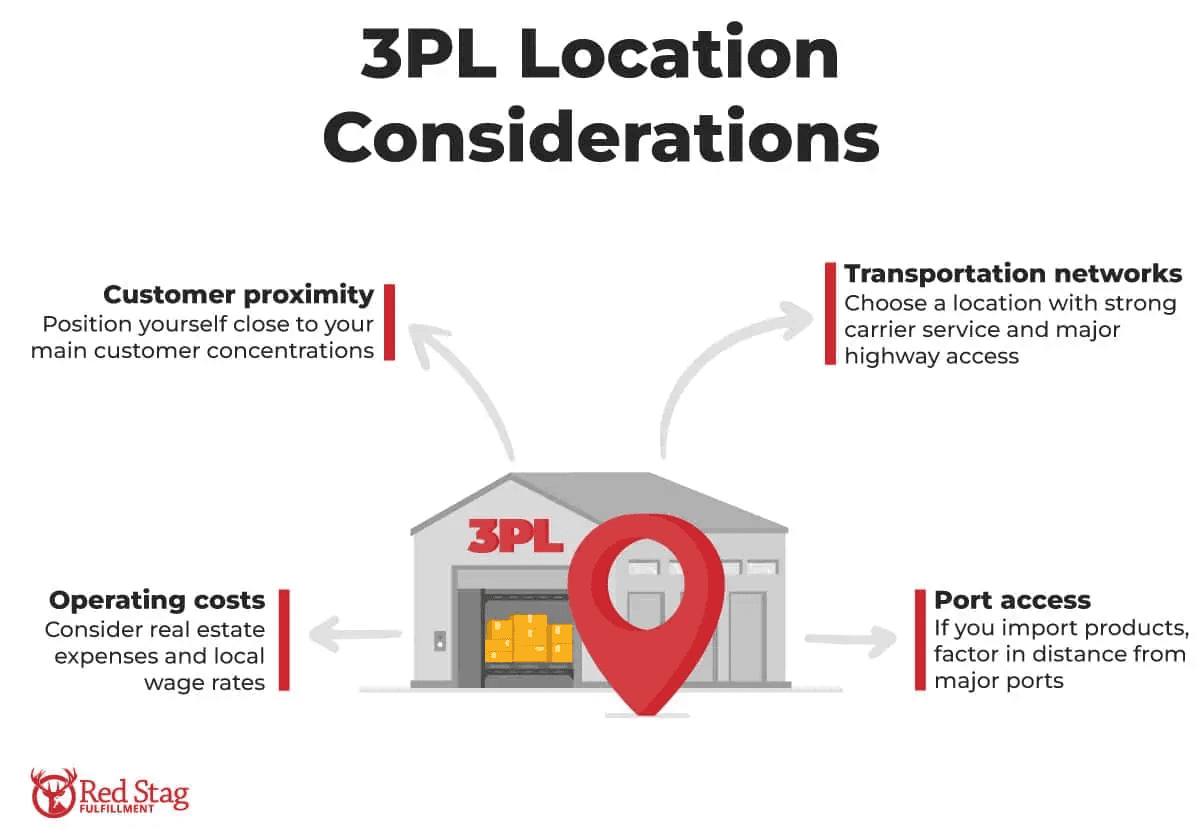

6. Choose the Right Warehouse Strategy & Location(s)

Warehouse location matters, but strategy depends on your business size and goals. Optimize your supply chain through smart location choices.

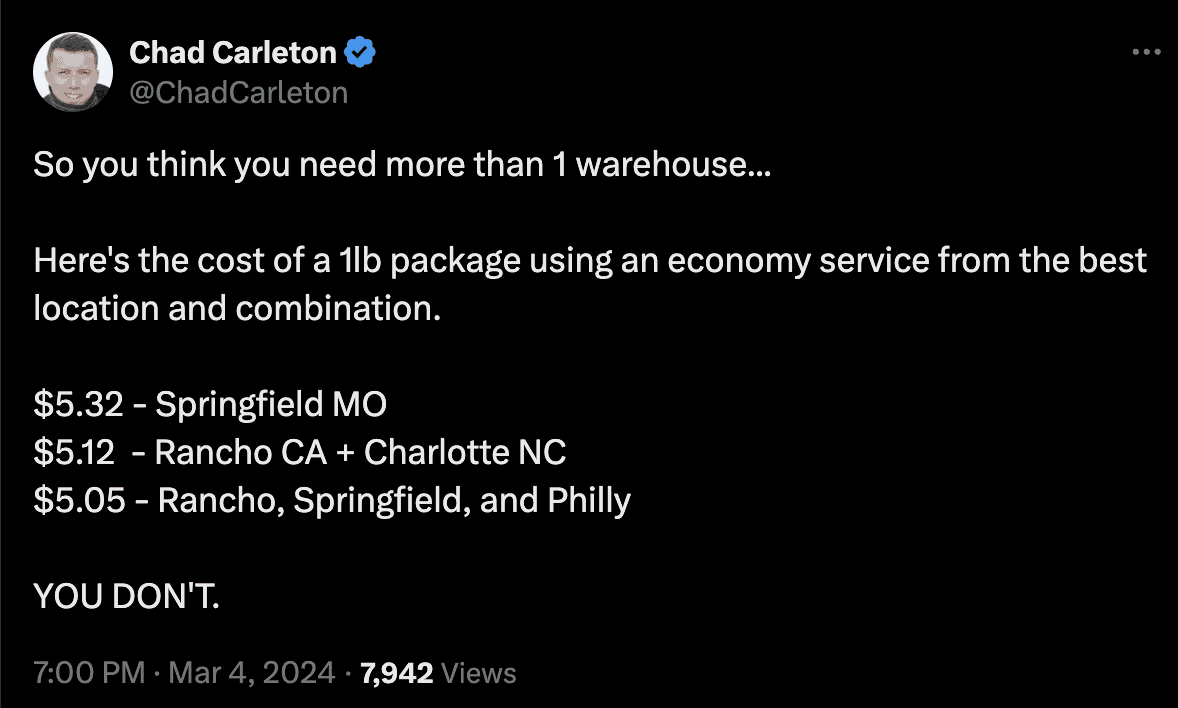

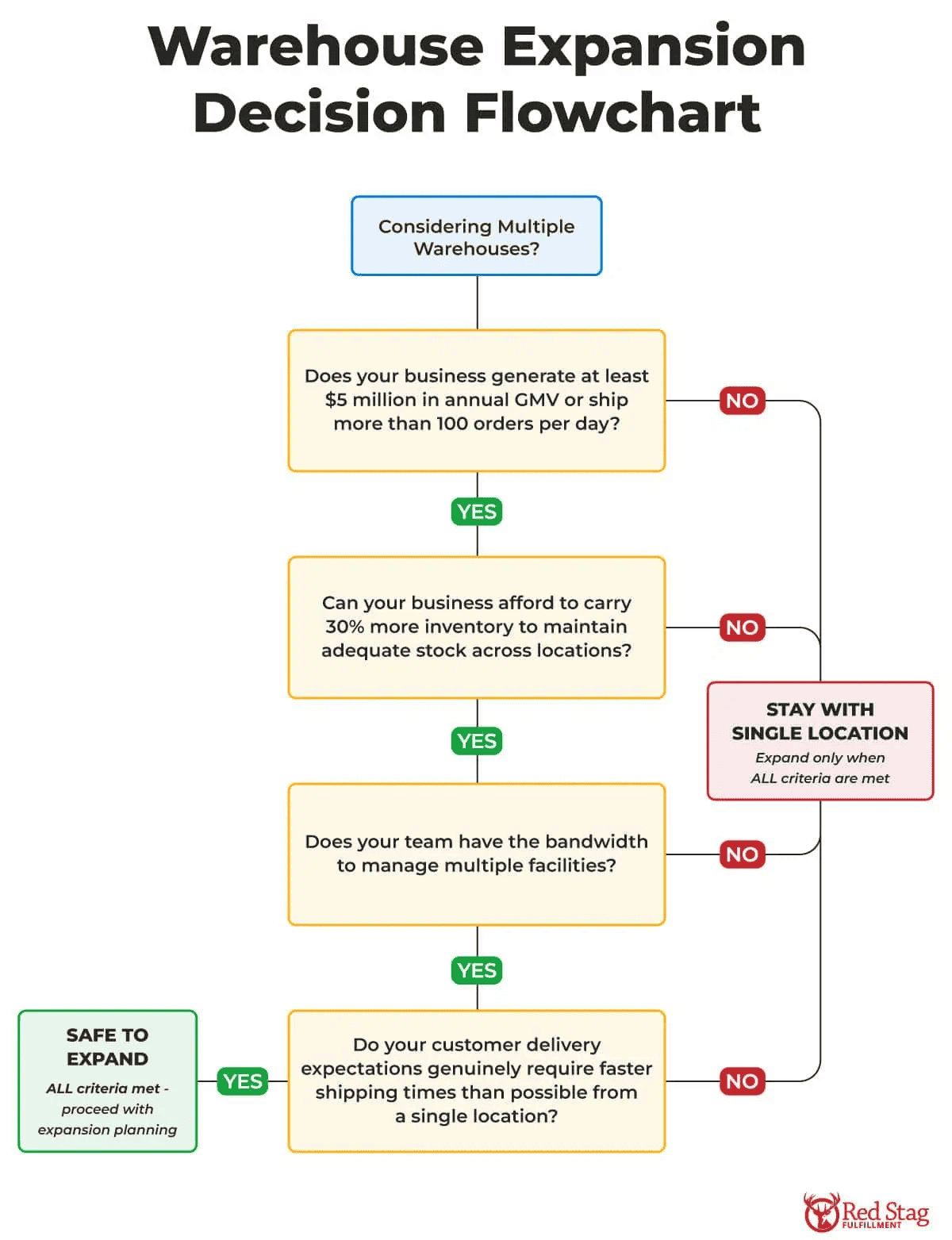

Start Strategically: Single vs. Multiple Locations

Vast networks aren’t always better, especially for smaller/growing businesses.

- Single Location Works Best If: Shipping < ~100 orders/day or < ~$5M GMV. Choose based on customer proximity, transportation networks, operating costs, and port access (if importing).

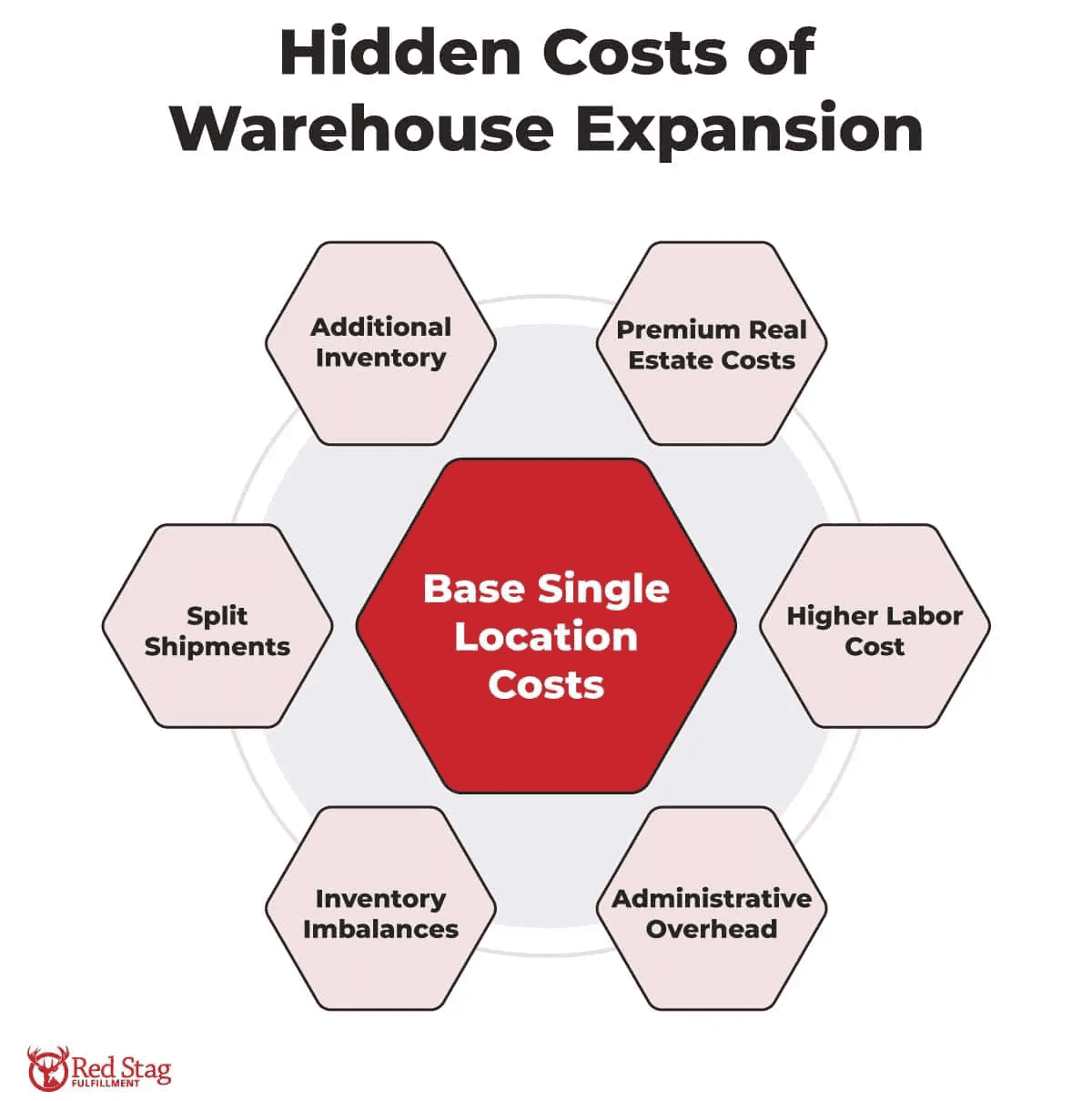

- Cost of Multiple Locations: Adds significant complexity and cost to logistics operations:

- Increased Inventory: Often requires 30%+ more stock overall, complicating inventory management.

- Higher Operating Costs: Managing multiple facilities (fulfillment centers), potentially higher real estate/labor costs.

- Complexity: Inbound logistics, inventory balancing, potential for costly split shipments.

As Rich Patterson, former enterprise sales director at ShipBob, explains: “If you’re not producing close to 5 million in GMV, or only ship 50-100 orders per day, you don’t need multiple locations.”

Expand Only When Clearly Justified:

When we started with Red Stag, we were in one warehouse because we didn’t have enough volume to split it up. Then, as we grew, we eventually split inventory between two warehouses.

Jon Blair

Founder

Free to Grow CFO

Consider multiple locations only if:

- Volume savings clearly outweigh added costs.

- You can efficiently manage inventory across locations.

- Your team has bandwidth for complexity.

- Faster delivery is a proven critical factor unmet by a single location. Consider other factors beyond just speed.

International Considerations: Often best handled by regional specialists due to complexity (customs, regulations). Expand only when data supports it.

Key Takeaway: Don’t over-distribute prematurely. Start with one strategic location unless order volume and customer needs demonstrably justify the added cost/complexity of multiple fulfillment centers.

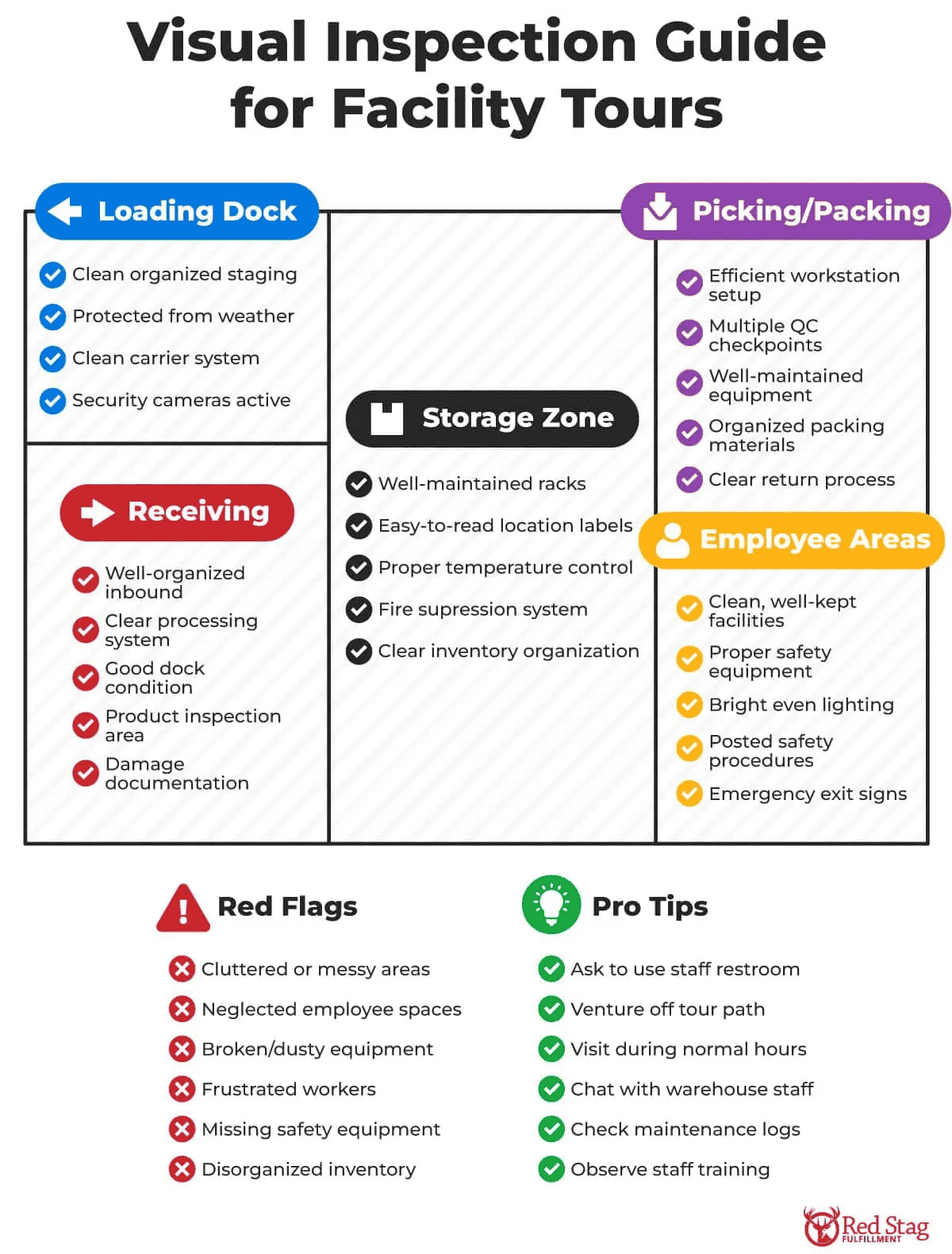

(Bonus) Inspect Warehouse Conditions: What Visuals Reveal

If possible, visit facilities in person for invaluable insights into operational quality and adherence to safety regulations.

Look Beyond the Staged Tour:

Observe overall cleanliness, organization, and condition – these reflect attention to detail in their logistics operations.

Pro Tip: Ask to use an employee restroom. Its condition often reveals more about standards than polished areas.

Facility Inspection Checklist:

- Docks/Receiving: Organized? Protected? Efficient flow? Secure? Orderly processing?

- Storage: Maintained racks? Clear labels? Temp control? Fire safety? Good lighting? Neat inventory storage?

- Picking/Packing: Efficient layout? Tools available? QC checks? Organized materials?

- Equipment: Clean, maintained? Maintenance logs?

- Employee Areas: Clean? Safety procedures posted?

- Overall: Cleanliness? Clear aisles? Lighting? Safety equipment? Engaged staff?

Red Flags During Visit: Clutter, dirt, disorganization, broken/poorly maintained equipment, damaged inventory, missing safety gear, disengaged staff.

Key Takeaway: A disorganized or poorly maintained facility often signals deeper operational problems. While cleanliness isn’t everything, dirtiness almost always predicts issues for a logistics provider.

Conclusion: A Methodical Approach is Key to Success

Choosing the right third party logistics provider requires moving beyond surface comparisons. Systematically evaluate potential partners across these critical dimensions: requirements, total cost, verified performance (key metrics like order accuracy), technology, stability/scalability, communication, and operational quality. This is how many businesses find success.

Remember Sarah from Bare Nut Butter’s advice: “get everything in writing, look at total cost, verify processes.”

Investing time in a thoughtful evaluation helps forge a strong partnership that supports business growth and customer satisfaction, avoiding the disruption of a costly switch. Aim for a long term partner, not just the lowest cost option available for your business today.

Ask potential 3PLs about their performance metrics from previous peak seasons. The concrete data about their holiday shipping times and error rates will tell you far more than promises about peak season readiness.

At Red Stag Fulfillment, we take a consultative approach to partnership discussions. Our goal is simple: help you find the right 3PL for your business—even if that’s not us.

Rather than rushing to provide generic quotes, our team invests time upfront to thoroughly understand your:

- Current fulfillment challenges and pain points

- Product handling requirements and specifications

- Growth plans and scaling needs

- Technology integration requirements

- Customer experience goals

This detailed discovery process helps us determine if we can be the right long-term partner for your business. And if we’re not the best fit, we’ll tell you directly and help point you toward providers better suited to your needs. We’ll help you work through each evaluation step outlined in this guide, sharing concrete data about capabilities and performance guarantees.

Remember: Switching 3PLs is expensive and disruptive. Whether you choose Red Stag or another 3PL, taking the time upfront to thoroughly evaluate potential partners helps avoid a costly transition down the road.

Ready to start a thoughtful conversation about your 3PL fulfillment needs? Reach out today.