When logistics managers face constant pressure to cut shipping costs, maximizing container space becomes a critical solution. But

what if you could fit 15-25% more product into every shipment by eliminating pallets?

This comprehensive guide explores that trade-off through the lens of floor loaded container strategies, helping you understand when this approach makes financial sense and how to implement it safely and compliantly.

Beyond simple cost savings, this method requires careful consideration of product characteristics, destination requirements, and operational capabilities to determine if the increased labor costs and complexity align with your business goals.

What you’ll learn

The core definition of a floor-loaded unit and how it differs from standard palletized shipping

A head-to-head comparison of floor loading vs. palletizing on cost, speed, and risk factors

When to use (and when to avoid) floor loading for your specific freight based on product type and destination requirements

A step-by-step guide to safely and compliantly floor load a unit with proper planning and execution

How to calculate capacity limits and navigate compliance requirements like Amazon FBA rules

TL;DR:

Key takeaways

Floor loading can reduce shipping costs by 15-25% but increases labor costs and requires careful planning

Product type and destination rules (like Amazon FBA requirements) are critical decision factors that determine feasibility

A proper floor load plan with appropriate equipment and safety measures is essential to prevent damage and ensure compliance

Understanding weight distribution and capacity calculations helps maximize space while staying within legal limits

What does “floor loaded container” actually mean?

A floor loaded container is a shipping container packed directly from the unit floor up without pallets. Individual boxes or items are stacked tight to fill every inch of space, reducing pallet weight and maximizing capacity. It’s ideal for durable, bulky freight where shipping costs savings outweigh handling speed.

The primary goal of floor loading is to utilize the space and weight capacity that wooden platforms would otherwise consume. Think of it like meticulously packing a suitcase to use every inch of space, versus using bulky packing cubes that take up valuable room but make organization easier.

This approach contrasts sharply with palletized loading, which is the standard method in most supply chains. Standard loading involves pre-stacking goods on wooden platforms, shrink-wrapping them into stable units, and then using a forklift to load these units into the shipping unit. While this method prioritizes speed and ease of handling, it sacrifices valuable space that a floor loading strategy reclaims.

Floor loading also allows for more creative stacking patterns and configurations that aren’t possible when constrained by standard platform dimensions. This flexibility can be particularly valuable when shipping irregularly shaped items or when trying to maximize the use of every cubic inch of available space.

PRO TIP: When evaluating floor loading strategies, always ask for client references from businesses similar to yours in size and complexity to understand real-world implementation challenges.

Floor loading vs. palletizing: A head-to-head comparison

While floor loading seems like an obvious win for space utilization, the decision involves critical trade-offs in cost, risk, and labor that require careful analysis.

| Metric | Floor Loading | Palletizing |

|---|---|---|

| Space Utilization | Excellent (up to 100%) | Good (85-90%) |

| Per-Unit Shipping Cost | Lower | Higher |

| Labor Costs (Load/Unload) | High (Manual) | Low (Forklift) |

| Damage Risk | High if packed poorly | Lower, but risk of fork damage |

| Speed to Load/Unload | Slow | Fast |

| Equipment Needs | Dunnage, straps, labor | Forklift, pallet jack |

Capacity and cost breakdown

Removing wooden platforms can significantly increase usable space and reduce the number of units needed for large shipments. Floor loading reduces shipping costs by 15–25% by eliminating wooden supports and maximizing space utilization. This cost reduction comes from both the elimination of platform weight (typically 30-48 lbs per wooden support) and the ability to pack items more tightly without size constraints.

However, these savings come with hidden costs that must be factored into your total landed cost. Manual labor to load and unload takes significantly longer than forklift operations. Unloading takes 4–8 man-hours versus 1–2 hours for a standard shipment. Additionally, slower unloading times can trigger carrier detention fees, which are key components of 3PL pricing that can significantly impact your total landed cost.

The financial impact becomes more complex when you factor in warehouse receiving capabilities. Some facilities charge premium rates for manual unloading, while others may not have the labor capacity to handle floor-loaded shipments efficiently during peak periods.

ALERT: Never sign a long-term contract without performance guarantee clauses that protect you from detention fees and service delays.

Damage and liability considerations

A tight, well-executed floor loading can actually be more secure than standard freight because items are packed wall-to-wall with no movement possible. However, this requires expert execution and proper planning. The risk comes from improperly packed loads where shifting can occur, potentially causing catastrophic damage to entire shipments.

Standard freight is generally more stable during transport due to the rigid base and shrink-wrap containment, but it’s not immune to damage. Forklift punctures, platform collapse, and load shifting during transport can still occur with traditional goods.

The liability considerations extend beyond just physical damage. Insurance coverage may vary between floor-loaded and standard shipments, with some carriers requiring additional documentation or inspection protocols for manually loaded freight.

When is floor loading the right strategy for your freight?

The decision to floor load depends heavily on three critical factors: the product characteristics, destination requirements, and your operational priorities.

Ideal products for floor loading:

Durable, uniform boxes (e.g., shoes, books, small consumer goods) that can be tightly stacked without damage

Large, sturdy, and self-supporting items (e.g., tires, furniture, rolled carpet) that don’t require additional structural support

Lightweight but high-volume freight where the goal is to “cube out” the unit rather than “weigh out” within weight limits

Businesses shipping bulky goods like tires and furniture saved 22% in logistics costs with floor loading strategy.⁴ This approach is particularly effective for companies specializing in shipping heavy or bulky cargo where traditional configurations waste valuable space.

Red flags – when to avoid floor loading:

Fragile or high-value goods where compression damage or shifting poses unacceptable risk

Mixed-SKU shipments with varied box sizes that create instability and gaps in the load

Destination requires wooden platforms as many large retailers and Amazon fulfillment centers require standard shipments for efficient receiving

Speed is the #1 priority when you need to unload quickly and turn dock doors efficiently

The decision also depends on your supply chain’s flexibility and the receiving facility’s capabilities. Some destinations simply cannot accommodate the extended unloading times that floor-loaded shipments require.

NOTE: Amazon FBA has specific requirements for floor-loaded shipments that must be followed exactly to avoid rejection and additional fees.

How to floor load a container safely and effectively

A successful floor loading isn’t about cramming as much as possible into a unit; it’s a methodical process requiring careful planning, proper equipment, and strict adherence to safety protocols.

Pre-load planning and equipment

Before touching a single box, create a detailed load plan that accounts for weight distribution, item compatibility, and securing methods. Essential equipment includes dunnage (airbags, cardboard), load bars, and straps—all designed to prevent load shift during transport.

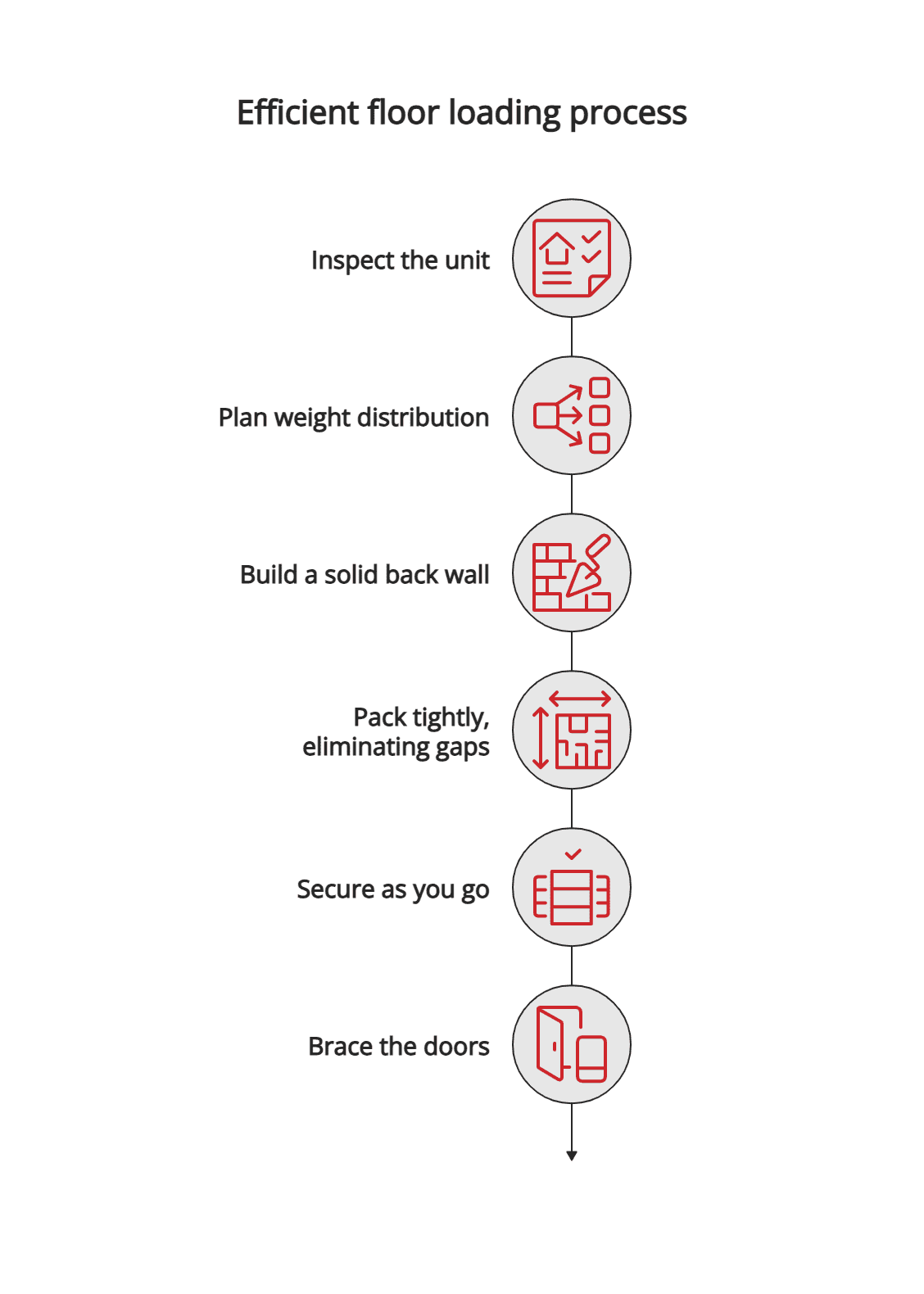

Step-by-step floor loading process

01

Inspect the unit. Check for leaks, structural damage, and odors that could contaminate your freight. Ensure the floor is clean, dry, and free of debris or protruding nails.

02

Plan weight distribution. Start with heavier items on the bottom and distribute weight evenly across axle areas to comply with road weight limits. Poor weight distribution can result in overweight citations and unsafe driving conditions.

03

Build a solid back wall. Create a tight, interlocking “brick” pattern from floor to ceiling at the rear of the unit. This wall serves as the anchor point for the entire load and prevents forward shifting.

04

Pack tightly, eliminating gaps. Pack boxes “high and tight” to prevent any movement during transport. Use dunnage to fill unavoidable gaps between items of different sizes.

05

Secure as you go. For long units, use load bars or straps to create internal bracing sections as you complete them, essentially creating internal walls that prevent cascading shifts.

06

Brace the doors. The final few feet of the load are most critical for safety. Use strong dunnage and load bars to prevent freight from falling out when doors are opened at destination.

PRO TIP: When planning your floor loading, always account for the 3″ clearance requirements and height restrictions that many destinations impose.

Safety and Amazon FBA compliance

OSHA guidelines for freight securement apply to all floor loading operations, emphasizing the importance of proper bracing and weight distribution. For Amazon FBA destinations, floor-loaded shipments face particularly strict requirements.

Amazon requires 3″ clearance between stacks and walls, a maximum stack height of 72″, and prohibits bundling boxes with straps or tape. Additionally, boxes over 50 lbs are subject to refusal. These complex rules are a key reason many sellers partner with a 3PL for Amazon to ensure compliance and avoid costly rejections.

Calculating floor load capacity to maximize space and avoid fees

Floor loading capacity isn’t a single number but rather a balance between two critical constraints: the unit’s internal volume (cubic capacity) and its maximum payload weight.

Understanding the two constraints

Standard specifications provide the framework for your calculations:

20ft Unit: ~1,172 cubic feet / ~48,000 lbs max payload

40ft Unit: ~2,390 cubic feet / ~61,200 lbs max payload

Practical calculation example

Consider freight consisting of boxes that are 1 cubic foot each and weigh 30 lbs. A 40ft unit has a ~61,200 lb payload limit, so you will “weigh out” (hit the weight limit) at 2,040 boxes, long before you “cube out” (fill the 2,390 cu. ft. of space). Understanding whether you’ll weigh out or cube out first is essential for planning your floor loading and determining cost-effectiveness.

OTHER: Quick Tip: Always check the unit’s specific data plate (CSC Plate) for exact maximum weights, as specifications can vary between types and ages.

Remember to account for the weight of dunnage and bracing materials in your calculations, as these can add several hundred pounds to your total load weight.

Frequently asked questions

Is floor loading always cheaper?

Not always. Floor loading reduces per-unit shipping costs but significantly increases labor costs to handle. It’s most cost-effective when your products are durable and the receiving warehouse has efficient, low-cost labor capabilities.

Does Amazon accept floor-loaded containers?

Yes, but with strict receiving rules and a separate appointment type. Your shipment can be delayed or rejected if it doesn’t meet their exact packing standards. Amazon’s Partnered Carrier Program for LTL shipments does not accept floor loaded freight.

How long does it take to unload a floor-loaded container?

It typically takes two people 4-8 hours to manually unload a 40ft unit, compared to just 1-2 hours for a standard one using forklift equipment.

Are there extra fees for floor-loaded freight?

Yes. Most 3PLs and warehouses charge a “floor load surcharge” or “manual unload fee” to cover the additional labor requirements. Understanding these potential fees is a critical part of how to choose a 3PL that aligns with your operational needs and budget.

READ MORE: For more guidance on selecting the right logistics partner for your floor loading operations, see our comprehensive guide to 3PL services.

Citations

- Amazon Seller Central. “Floor Loading Policy.” https://sellercentral.amazon.com/gp/help/external/G200978440.

- Amazon Seller Forums. “Shipping a full container floor loaded.” https://sellercentral.amazon.com/seller-forums/discussions/t/5475e2fa4edb62f3368266bce7d54cea.

- LaborLoop. “How Long Does It Take to Unload a Shipping Container?” https://www.laborloop.com/how-long-does-it-take-to-unload-a-shipping-container/.

- Orkestra SCS. “Top Strategies to Improve Your Container Utilization.” https://www.orkestrascs.com/blogs/underutilized-container-space.