Drayage is an intermodal transportation process that helps reduce delays and improve the efficiency of large freight transport modes such as sea, air, and rail. Understanding the role drayage plays will help you tackle its complexities and stay compliant when shipping goods via multiple modes of transport.

Regulatory compliance, drayage fees, and risk mitigation all affect bottom-line performance and customer satisfaction. So it’s critical that you’re knowledgeable across these key areas when selecting a drayage service.

Here we explore the ins and outs of drayage: what it means, the various types of drayage services and fees, and how to optimize the drayage process.

What you’ll learn

Definitions for the nine main types of drayage services

Best practices for working with drayage providers

Factors that affect drayage fees

TL;DR:

Key takeaways

Quick definition: Drayage is short-distance freight transport that connects different modes of transportation (sea, rail, air, road).

Why drayage matters: Reduces congestion, prevents delays, and improves efficiency in intermodal shipments.

Types of drayage services: Common types include shuttle, inter-carrier, intra-carrier, pier, rail, door-to-door, expedited, repositioning, and warehouse drayage.

Drayage fees and best practices: Fees depend on cargo type, distance, waiting times, and special handling. Effective cost management requires clear communication, careful provider selection, and regular performance monitoring.

What is drayage?

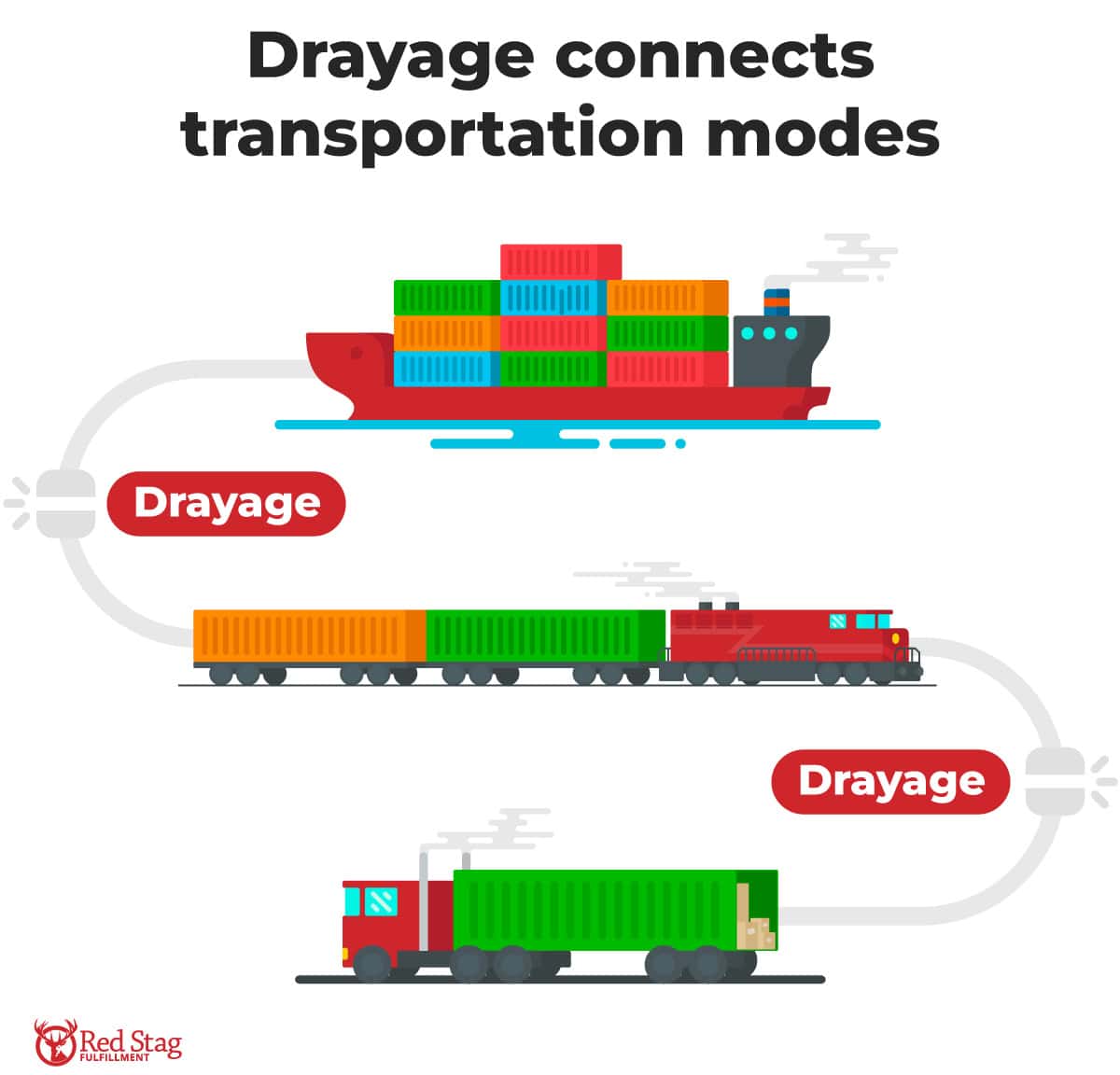

Drayage is a short-distance transportation method that connects transport modes, such as ship, air, and train, for larger freight. It’s an integral facilitator of intermodal transport that allows for a seamless flow of goods—reducing total shipping times by ensuring efficient freight movement without delays.

Unlike long-haul trucking, which typically delivers goods directly to the final destination, drayage focuses on connecting two modes of transport within a single delivery task.

Import/export managers, logistics coordinators, and small business owners shipping internationally need to understand drayage, as they’ll either arrange these services directly or pay for them through their freight forwarders or shipping lines.

The responsibility for selecting a drayage provider varies by scenario. For international shipments, your freight forwarder typically arranges drayage services. For domestic intermodal shipping, the shipper (you or your business) often selects the provider directly. Large shippers may have standing contracts with drayage companies, while smaller operations might rely on third-party logistics providers to coordinate these services.

PRO TIP: If you work with Red Stag Fulfillment, we have a hands-off freight management service that will coordinate your drayage (and all other aspects of moving your freight).

For example, if you’re importing generators from China to your warehouse in Tennessee through a Texas port, your freight forwarder would typically arrange for drayage services to move your containers from the port to a rail yard. You’d see these charges itemized on your shipping invoice, alongside customs fees and other handling costs.

Regulatory compliance is another important consideration in drayage operations, with requirements varying by port, region, and shipment type—a factor we’ll explore more throughout this article.

Why intermodal drayage plays an important role in the shipping process

Drayage helps speed the shipping process by ensuring a seamless transition between intermodal transportation methods. It prevents jams at busy ports or shipping hubs through reduced container dwell time, which in turn prevents goods from being delayed in reaching their final destination.

More simply, drayage makes intermodal shipping—particularly international shipments of larger freight—easier and more efficient. It also helps shippers reduce container storage fees, avoid detention fees, and minimize fuel and labor costs by accelerating container movement.

As a result, drayage offers two-way benefits for both the shipper and receiver. The receiver gets the goods they need faster, and the shipper saves on costs and avoids disappointing customers with unsatisfactory service.

Different types of drayage services

Drayage isn’t a one-size-fits-all service. Multiple types of drayage are available. Your primary transport methods typically determine the best fit.

Common types of drayage services:

Shuttle drayage

Inter-carrier drayage

Intra-carrier drayage

Pier drayage

Rail drayage

Door-to-door drayage

Expedited drayage

Repositioning drayage

Warehouse drayage

Let’s quickly break down what these are and when you might need them.

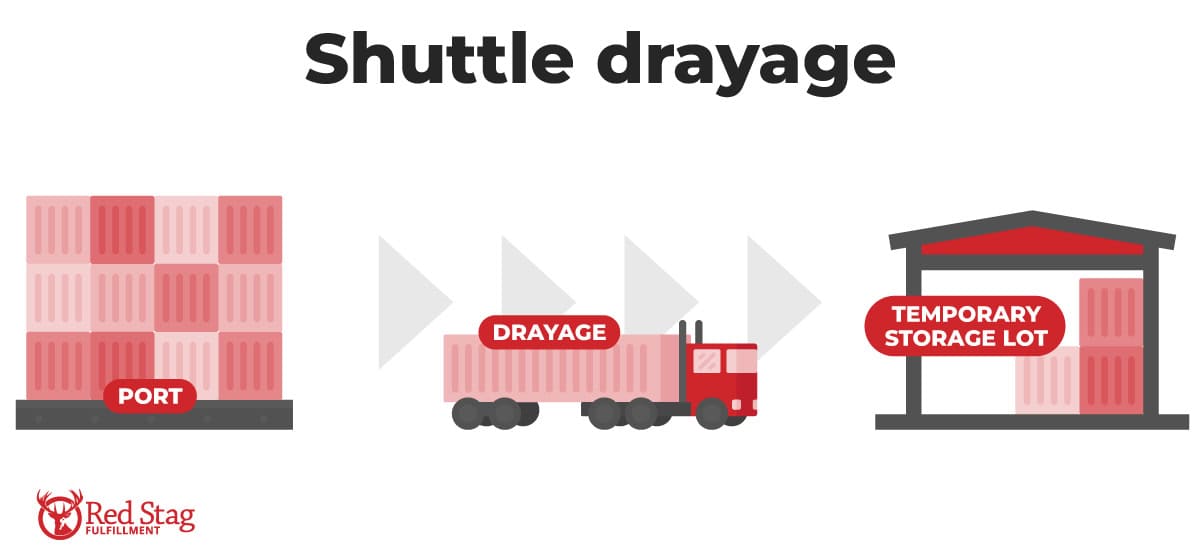

Shuttle drayage

Shuttle drayage involves moving containers from a primary hub (like a rail yard or port) to a secondary, temporary storage location. It’s commonly used when the primary hub reaches capacity. To prevent congestion, containers are shuttled to nearby storage lots until they can be transferred to their next mode of shipping.

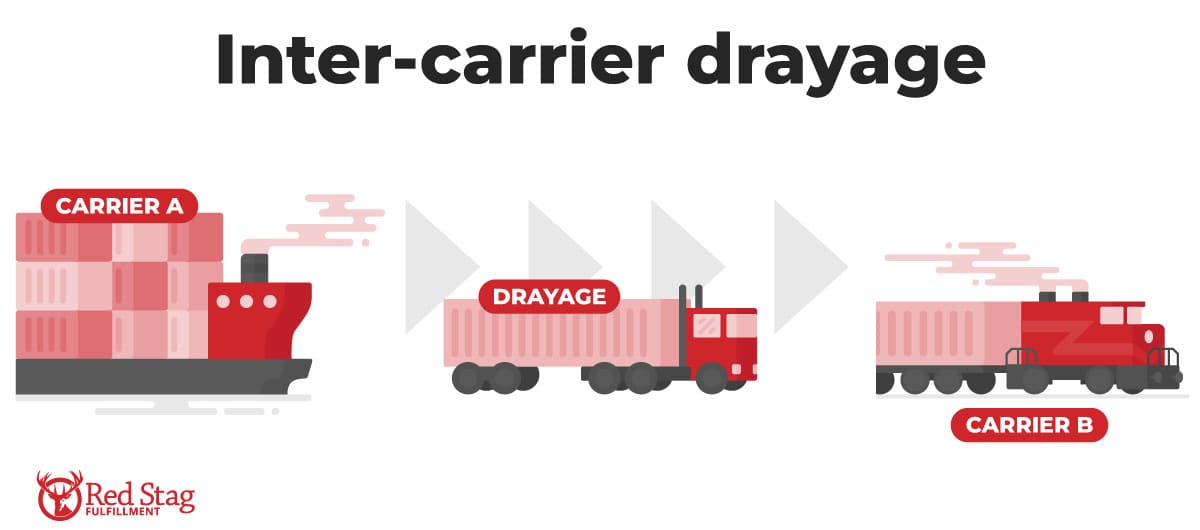

Inter-carrier drayage

Inter-carrier drayage transfers cargo between different transportation companies. For example, a truck might pick up cargo from a seaport and move it to a rail terminal.

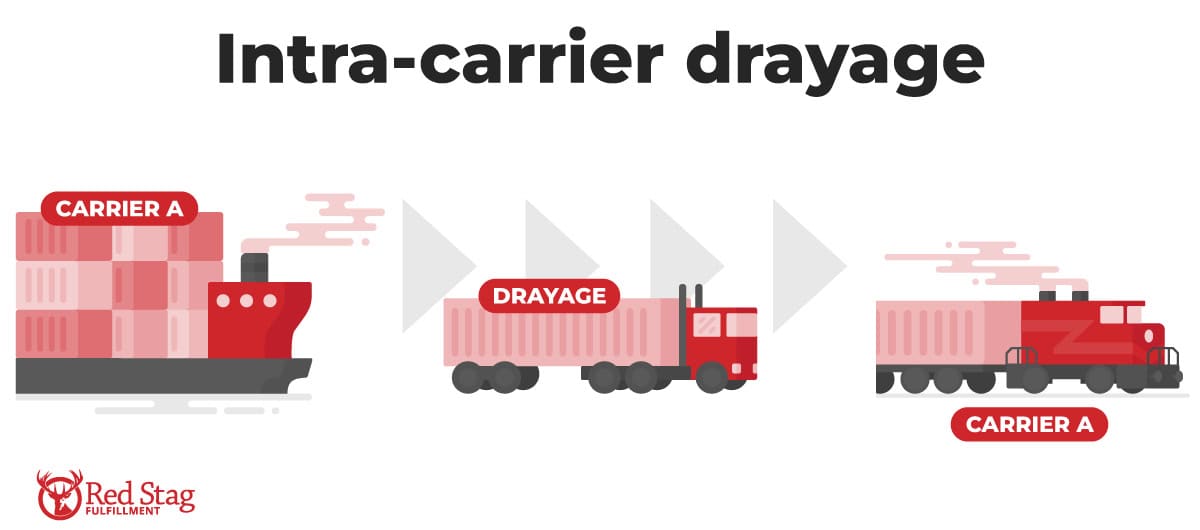

Intra-carrier drayage

Intra-carrier drayage is the transportation of goods between two different locations or transport modes operated by the same company. For example, a rail company might move a container from one of its rail terminals to another rail terminal within the same city. Intra-carrier drayage supports internal logistics for the same company, and it’s used to consolidate shipments for more cost-effective shipping.

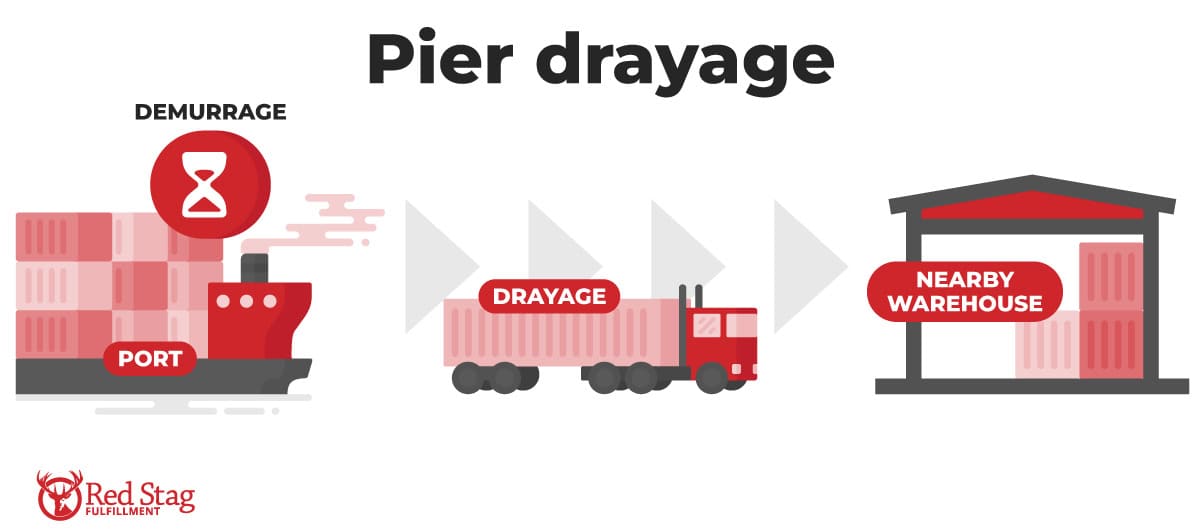

Pier drayage

Pier drayage, aka port drayage, involves the movement of shipping containers or other cargo between a ship at a port and another nearby location, such as a warehouse, distribution center, or rail yard. If a container remains at a port terminal longer than the allotted time (assigned by the shipping line or port authority), the container incurs an extra charge called demurrage. Pier drayage helps to avoid this extra charge.

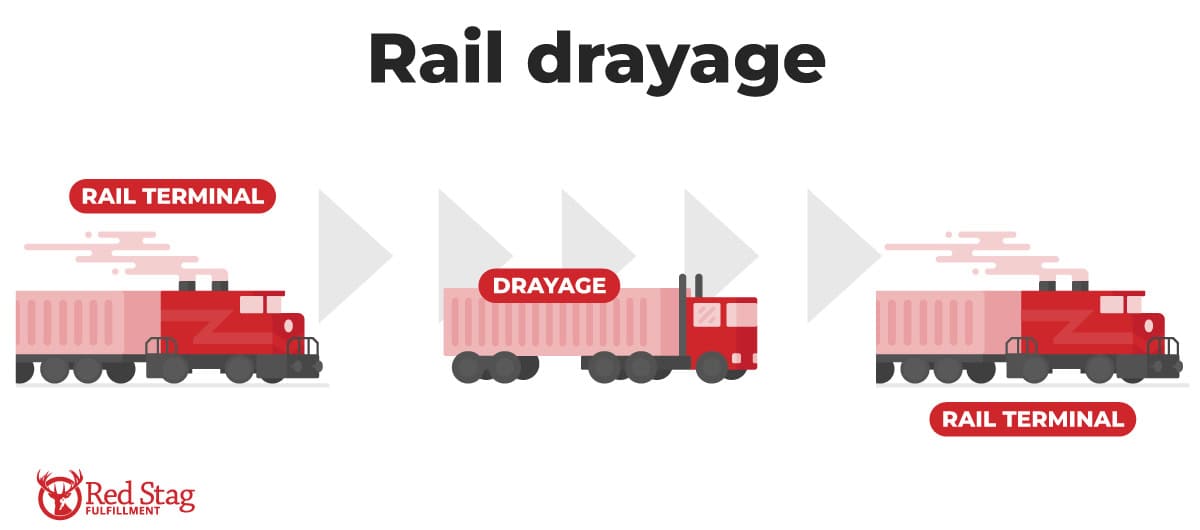

Rail drayage

Rail drayage connects rail transportation to other points in the supply chain. This typically involves trucking intermodal containers to and from rail terminals.

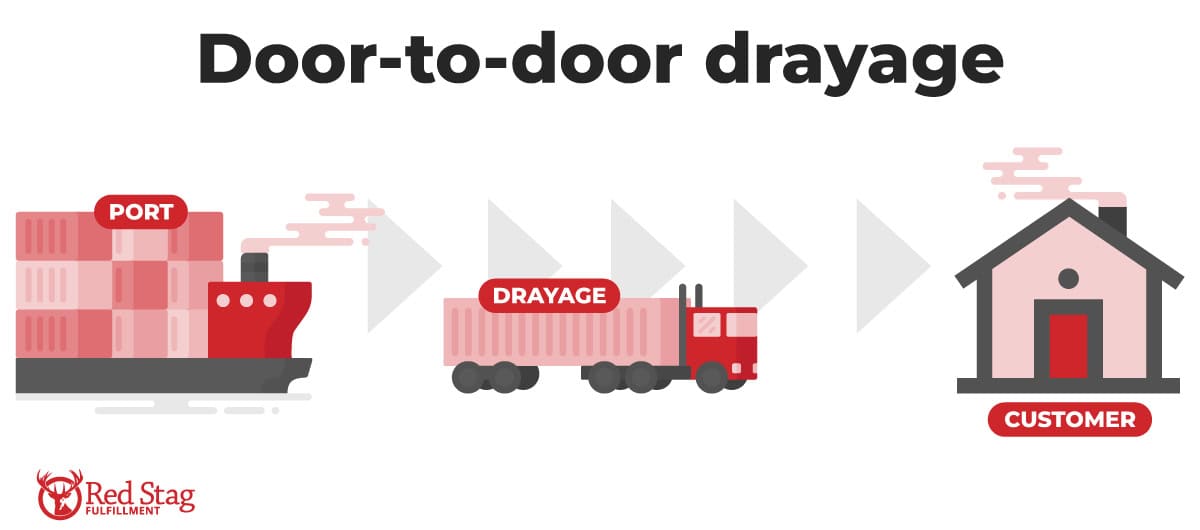

Door-to-door drayage

Door-to-door drayage transports containerized cargo directly from transportation hubs—ports, rail yards, or intermodal terminals—to the end customer’s location without intermediate stops. Functioning as the crucial “last-mile” connector in intermodal shipping, this service streamlines delivery by eliminating additional handling points and moving goods efficiently from hub to final destination. This direct approach reduces both transit time and the risk of damages that can occur during multiple transfers.

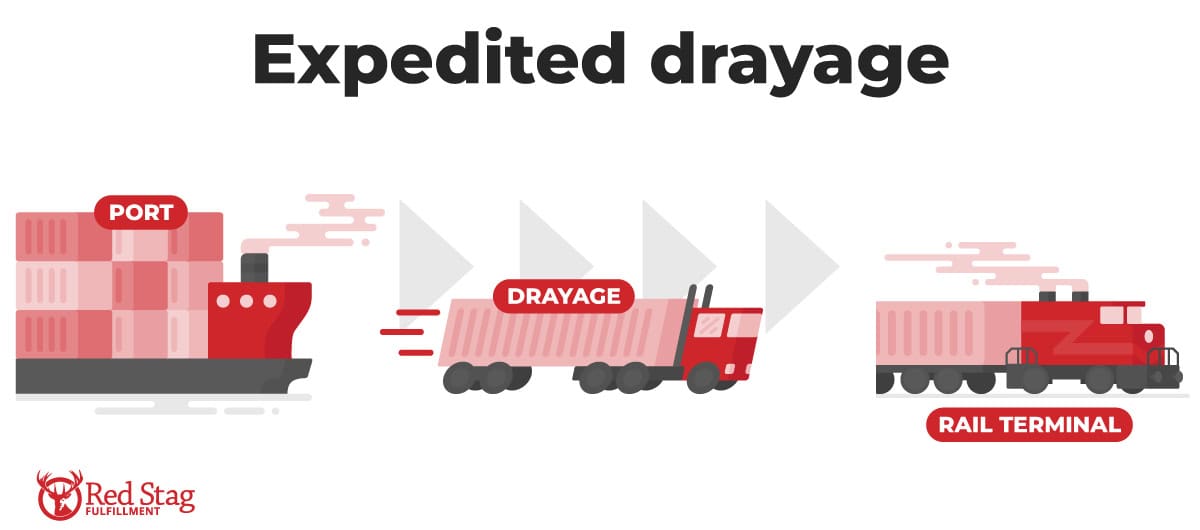

Expedited drayage

Expedited drayage refers to any type of time-sensitive drayage service whereby shipments must meet strict deadlines. It involves prioritizing the quick movement of urgent deliveries from one transportation mode or facility to the next.

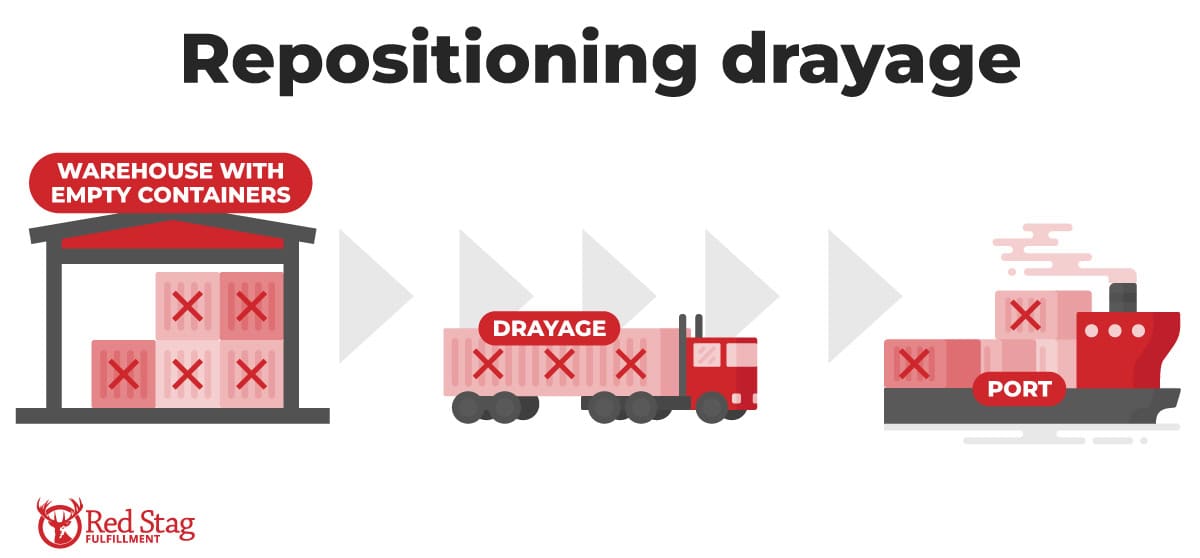

Repositioning drayage

Repositioning drayage involves moving empty containers from areas of surplus to areas where demand is high. One example is transporting empty containers from a warehouse back to a port or rail yard.

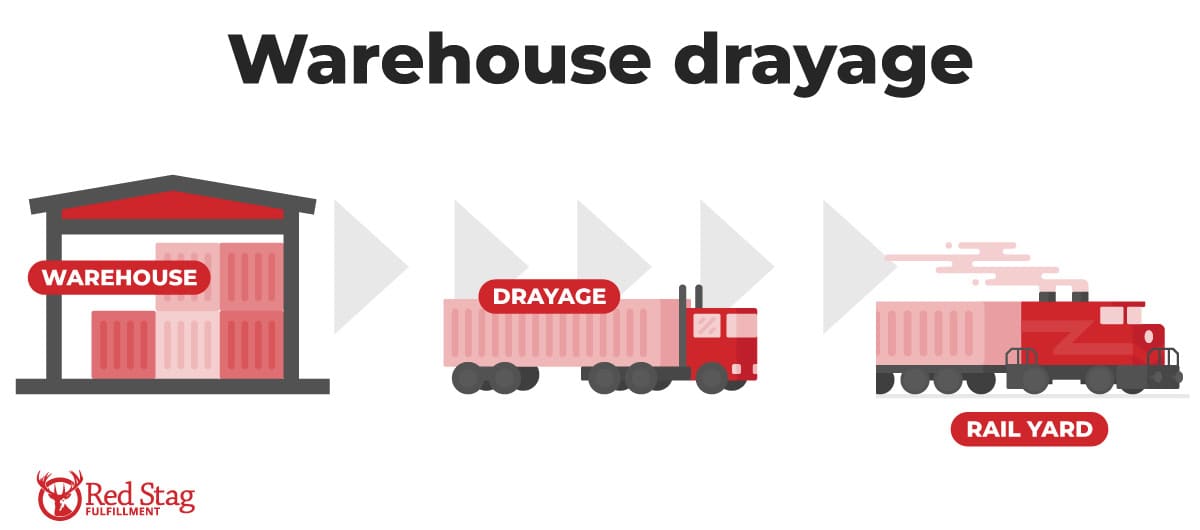

Warehouse drayage

Warehouse drayage specifically involves a warehouse as either the origin or the destination of the cargo. It might move containers from a port to warehouses for storage or distribution. Or, it might move containers from warehouses to rail yards for further transport.

Drayage fees and pricing

Cost is an important consideration when investigating drayage services.

Drayage fees are the charges associated with the drayage process. They cover the operational costs of drayage services as well as additional costs that apply to specific circumstances or requirements.

Typical drayage fees include:

- Base drayage fee.

The standard charge for the outlined drayage service that’s being provided. - Per-mile fee.

An additional charge applied for every mile traveled beyond the standard distance included in the base drayage fee. - Chassis fees.

Additional charges for using a specialized trailer, known as a chassis, to transport goods between two intermodal transport hubs. - Fuel surcharge.

A fee designed to offset variable fuel costs during the drayage process. - Detention fees.

Charges incurred when drivers must wait longer than is permitted during pickup or dropoff. - Demurrage fees.

Additional charges for freight that remains at a transportation hub for longer than the allocated storage period. - Storage fees.

Costs incurred for holding goods at a port, terminal, or warehouse for longer than the allocated storage period. These differ from demurrage fees in that they’re typically charged by the shipping hub authority rather than the shipping line or carrier. - Drop fees.

Charges incurred when a truck delivers a shipping container to a location (e.g., a warehouse) and has to come back later to pick it up after the cargo is unloaded, instead of performing a live unload, where the container is unloaded immediately upon arrival. - Hazardous goods handling fees.

Extra costs for transporting hazardous materials (such as flammable gases). These are implemented to balance out the added compliance and safety requirements of shipping hazardous items. - Pre-pull fees.

The costs associated with collecting goods from a shipping hub and temporarily storing them in the drayage service provider’s yard to avoid demurrage and delays.

Many factors can affect drayage pricing and fees.

The type of cargo, shipment size, and delivery timeframe often determine which fees impact drayage pricing. Likewise, the distance of drayage service and specific compliance requirements may affect how much you pay for drayage.

Additionally, the location where drayage occurs can impact costs. Ports or shipping terminals may have their own fees and prices—and congestion at the location can increase the total fees you have to pay.

PRO TIP: To minimize drayage costs, consolidate shipments and negotiate better drayage contracts with service providers. Leveraging shipping software and optimizing your drayage scheduling to avoid demurrage and detention fees are also effective ways to reduce total drayage costs.

Best practices for working with drayage service providers

Selecting the right drayage provider for your circumstances is an important decision. It affects both the reliability and speed of your deliveries as well as your total costs for shipping goods to the final destination. However, optimizing that relationship is equally important.

These tips will help you select a provider and optimize the relationship:

- Evaluate suppliers carefully.

Consider their track record, expertise, compliance, location, and scalability. If you have specific needs, such as hazardous goods handling, pick a provider with experience in this area. - Prioritize clear communication.

Avoid delays, mishandling, and extra fees by clearly outlining your requirements and confirming that the provider fully understands what you need. - Monitor supplier performance.

To gain leverage when negotiating future contracts and keep your service providers accountable, track key performance metrics such as delivery times and service fees every time you commission a shipment.

Streamline your drayage and freight with Red Stag Logistics

As a Red Stag Fulfillment client, you get expert freight coordination included with your fulfillment service—a valuable addition that simplifies the complexities and fees associated with drayage services.

Red Stag Logistics coordinates your domestic freight at two critical points: getting your inventory from port to our warehouses and moving your products to B2B customers. Our U.S.-based logistics team brings over 50 years of combined experience to save you up to 20% on container costs while accelerating receiving by 24-48 hours.

Our integrated approach eliminates the communication gaps that typically occur between warehouses and shipping providers. We arrange container appointments, coordinate with drayage providers, and ensure timely delivery—all while providing real-time tracking and proactive issue resolution.Connect with our team today to learn how Red Stag’s integrated fulfillment and logistics solution can optimize your supply chain.