Your shipping bill just skyrocketed overnight. The culprit? Freight reclassification fees that blindsided your budget.

This happens to countless LTL shipments. The reason is simple: most shippers don’t understand how freight class works.

Freight class is a standardized system that determines your LTL shipping costs based on four factors: density, stowability, handling requirements, and liability. Classes range from low (cheapest) to high (most expensive).

Get it wrong, and carriers will reclassify your shipment—often adding substantial unexpected fees.

What you’ll learn

How freight classification determines your shipping costs

The four factors that affect your freight class

Step-by-step density calculation methods

Common mistakes that trigger reclassification fees

Strategies to optimize your freight costs

TL;DR:

Key takeaways

Freight classes range from 50 (cheapest) to 500 (most expensive)

Density is the primary factor in classification

25% of shipments face reclassification

Proper packaging can lower your freight class

Professional 3PL partners prevent classification errors

Understanding freight class basics

Freight class is a standardized system used by less-than-truckload (LTL) carriers to determine shipping rates based on your product’s characteristics. This freight classification system ensures fair pricing across the industry by grouping similar commodities together.

The National Motor Freight Traffic Association (NMFTA) was founded in 1956 and is headquartered in Alexandria, Virginia. This organization maintains the National Motor Freight Classification (NMFC) system that governs how all LTL freight shipments are priced and handled.

PRO TIP: Understanding freight class isn’t just about avoiding surprises—it’s about controlling your shipping costs. Proper classification can mean the difference between profitable and unprofitable shipments.

The NMFTA’s mission is to “promote, advance, and improve the welfare and interests of the motor carrier industry”. The National Motor Freight Traffic Association was founded during a critical period when the United States became an industrial powerhouse, creating increasingly complex freight transportation needs.

Every LTL freight shipment must be assigned a freight class between 50 and 500, with lower numbers representing cheaper shipping costs. This classification system creates predictability for both shippers and carriers while ensuring that pricing reflects the actual cost and risk of transporting different types of goods.

The four key factors that determine freight class

Freight class isn’t assigned randomly—it’s based on four specific criteria that carriers use to assess the transportation cost and risk of your shipment. These freight classifications depend on measurable characteristics that affect shipping complexity and cost.

Density (weight vs. space)

Density is the most important factor in determining freight class. It measures how much your shipment weighs relative to the space it occupies. Dense items like steel pipes ship cheaply, while light but bulky items like pillows cost more to transport.

NOTE: Density is calculated as pounds per cubic foot. A 50-pound box measuring 2′ x 2′ x 2′ has a density of 6.25 pounds per cubic foot (50 ÷ 8 cubic feet).

The density of your commodity directly impacts which freight class applies. Higher density typically means lower freight class numbers and cheaper shipping rates.

Stowability (loading compatibility)

Stowability refers to how easily your commodity can be loaded alongside other freight. Items that stack well and don’t have unusual shapes typically receive better freight classifications.

Hazardous materials, liquids that might leak, and oddly shaped items present stowability challenges. These commodities often receive higher freight class assignments because they limit how carriers can load their trailers.

For specialized handling of big and heavy items that require special loading considerations, carriers must dedicate more resources and potentially limit other freight options.

Handling requirements

Some commodities require special equipment or extra labor to load, unload, or transport safely. Items needing refrigeration, crane loading, or protective handling typically receive higher freight class assignments.

The NMFC guidelines specify when special handling affects freight class determination. Fragile items, hazardous materials, and extremely heavy pieces all fall into categories requiring additional carrier resources.

Liability risks

Carriers consider the potential for damage or loss when assigning freight class. High-value items or those prone to theft typically receive higher classifications to account for increased insurance and security costs.

Understanding these four factors helps you predict your freight class and identify opportunities to optimize your shipping costs through better packaging or commodity preparation.

Complete freight class chart and examples

The freight classification system includes 18 different classes ranging from 50 to 500, with each representing different shipping cost levels.

“An item that is Class 50 typically will be less costly to ship than an item that is Class 500”. This straightforward relationship means understanding your freight class directly translates to predicting your shipping expenses.

ALERT: The freight class scale expanded from 11 classes to 13 in July 2025, now including Classes 50 and 55. This expansion provides more precise classification options for very dense commodities.

| Freight Class | Density (lbs per cubic foot) | Typical Commodities |

|---|---|---|

| 50 | 50 and above | Cast iron, steel pipes |

| 55 | 35-49.9 | Cement, hardwood flooring |

| 60 | 30-34.9 | Car parts, metal products |

| 65 | 22.5-29.9 | Car accessories, bottled beverages |

| 70 | 15-22.4 | Food items, automobile engines |

| 77.5 | 13.5-14.9 | Tires, bathroom fixtures |

| 85 | 12-13.4 | Machinery, cast iron stoves |

| 92.5 | 10.5-11.9 | Computers, monitors |

| 100 | 9-10.4 | Boat covers, wine cases |

| 110 | 8-8.9 | Cabinets, framed artwork |

| 125 | 7-7.9 | Small appliances |

| 150 | 6-6.9 | Auto sheet metal parts |

| 175 | 5-5.9 | Clothing, couches |

| 200 | 4-4.9 | Aluminum table, packaged mattresses |

| 250 | 3-3.9 | Bamboo furniture, mattress and box spring |

| 300 | 2-2.9 | Wood cabinets, tables, chairs |

| 400 | 1-1.9 | Deer antlers |

| 500 | Less than 1 | Bags of gold dust, ping pong balls |

The cost difference between freight classifications can be substantial. A Class 50 shipment might cost $200, while the same weight and distance for a Class 500 shipment could cost $800 or more.

For ecommerce fulfillment operations, most consumer products fall between Class 85 and Class 200, making density calculation crucial for cost control and proper freight class assignment.

How to calculate freight density (step-by-step)

Accurate density calculation is essential for proper freight class determination and avoiding costly reclassification fees.

Gathering measurements

Start by collecting precise measurements and weights for your shipment. You’ll need a scale capable of weighing your entire shipment and measuring tools for length, width, and height.

Measure the packaged shipment—not just the product itself. Include all packaging materials, pallets, and protective wrapping in your calculations.

Step-by-step calculation

Follow this simple formula to determine your freight density:

Density = Weight (pounds) ÷ Volume (cubic feet)

01

Calculate volume: Multiply length × width × height (in feet)

02

Divide weight by volume: Use total shipment weight in pounds

03

Round to one decimal place: Most carriers round density calculations

Example calculation:

Shipment: 500 pounds

Dimensions: 4′ × 4′ × 3′ = 48 cubic feet

Density: 500 ÷ 48 = 10.4 pounds per cubic foot

Freight class: 100

PRO TIP: Always measure the complete shipment, including packaging and pallets. Carriers will reclassify based on the actual shipped dimensions, not just the product size.

Verification and rounding

Double-check your measurements and calculations before submitting your shipment. Use the calculated density to determine freight class according to the NMFC code guidelines.

Most carriers round density to the nearest tenth, so 10.44 becomes 10.4 pounds per cubic foot. This rounding can sometimes move you between freight classes, so precision matters for cost optimization.

Common freight classification mistakes to avoid

Classification errors are expensive and surprisingly common. Up to 25% of freight shipments undergo reclassification or reweighing, often resulting in unexpected charges and delays.

Most common errors

The biggest mistake shippers make is estimating rather than measuring their shipments. Guessing at weight or dimensions frequently leads to incorrect freight class assignment and subsequent penalties.

Failing to include packaging materials in calculations is another costly error. Carriers classify based on the complete shipment, including pallets, shrink wrap, and protective materials.

ALERT: Reclassification fees can increase shipping costs by hundreds or even thousands of dollars. Some carriers are reclassifying more than half of their LTL shipments.

Prevention strategies

Always weigh and measure your complete, packaged shipment before determining freight class. Document these measurements and keep photos as backup verification.

Create standard operating procedures for freight class determination to ensure consistency across your shipping operations. Train staff on proper measurement techniques and the importance of accurate classification.

Partner with experienced 3PL services that understand freight classification requirements and can help prevent costly errors through their expertise and established processes.

Cost optimization strategies

Smart shippers use legal methods to reduce freight costs through better freight class assignment while maintaining service quality.

Packaging modifications

Strategic packaging can improve your shipment’s density and potentially lower your freight class. Eliminating wasted space and using more compact packaging reduces volume without changing weight.

Consider using stronger, thinner packaging materials that provide the same protection with less bulk. This approach can shift your commodity to a lower freight classification category.

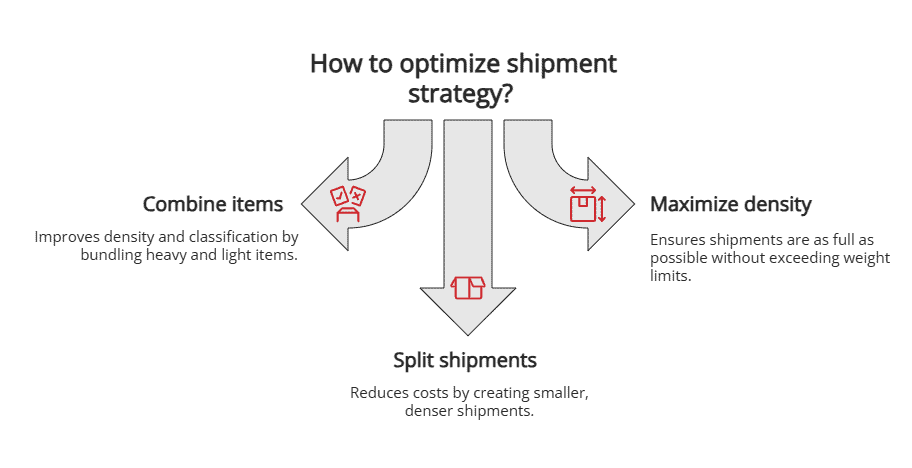

Product bundling strategies

Combining multiple items into a single shipment can improve overall density. Heavy items can be bundled with lighter commodity types to optimize the shipment’s classification.

Plan your shipments to maximize density while staying within weight limits. Sometimes, splitting one large, light shipment into two smaller, denser shipments can reduce total freight costs.

Partnership advantages

Working with third-party logistics partners provides access to LTL shipping expertise and carrier relationships that individual shippers can’t match.

LTL carriers often provide better service and rates to established logistics partners. These relationships can result in fewer reclassifications and more favorable dispute resolutions.

Long-term planning

Develop a supply chain strategy that considers freight class in product design and packaging decisions. Small changes in packaging or product configuration can yield significant ongoing savings.

Include freight classification considerations in new product development. Understanding how design choices affect shipping costs helps optimize your total delivered cost structure.

Regular analysis of your freight costs and shipping patterns reveals opportunities for classification optimization and cost reduction across your entire operation.

Citations

- BorderConnect. “National Motor Freight Traffic Association (NMFTA) (Customs Glossary).” BorderConnect Wiki, 1 Aug. 2023.

- National Motor Freight Traffic Association. “About NMFTA.” NMFTA, 5 Aug. 2025.

- Freight Class Calculator. “National Motor Freight Traffic Association.” FreightClassCalculator.us, 23 Nov. 2024.

- Zipline Logistics. “LTL Freight Classes FAQ and Freight Class Codes Chart.” Zipline Logistics Blog, 20 Feb. 2024.

- Resilient Freight Solutions. “NMFC Freight Class Changes in 2025.” Resilient Freight Blog, 2 Apr. 2025.

- My Freight World. “Can You Fight Freight Reclassification Fees?” My Freight World, 17 Feb. 2025.

- Ship TLI. “LTL Reclassification: How to Avoid Costly Fees.” Ship TLI, 12 Feb. 2025.

- Cargo Spectre. “The Rise of Reclassification Charges.” Cargo Spectre, 2025.