How will you know how much new product to produce for your next holiday? What kinds of capital will you need to invest in stock for your next fiscal year? Demand forecasting has the answers.

Demand forecasts project sales for the next few months or years. Different forecasting models look at different factors. You may want to employ multiple types of demand forecasts to get a well-rounded picture of potential opportunities and pitfalls.

No one can predict the future with absolute certainty; however, there are several demand forecasting techniques that use predictive analysis to help you make an educated guess.

In this article, we’ll cover those techniques and much more about demand forecasting, including its definition, types and methods, real-world applications, importance for businesses, potential challenges, and strategies for effective implementation.

TL;DR:

Key takeaways

Demand forecasting estimates future product demand, guiding production and inventory to meet consumer needs.

Combine passive, active, short-term, and long-term forecasting methods for comprehensive sales projections.

Use historical data, market research, expert opinions, and economic trends to inform forecasts.

Accurate forecasts require robust inventory management, supply chain communication, and data sharing practices.

Regularly evaluate forecast accuracy, adjust methods, and leverage 3PL partnerships to improve predictions.

What is demand forecasting?

Demand forecasting is the process of estimating future demand for a product or service.

Forecasting demand reveals how much product or service consumers may want to purchase over a period of time. Accurate demand forecasting helps businesses plan production in order to meet consumer demand. Overestimations or underestimations of customer demand can lead to excess inventory or a short supply of products.

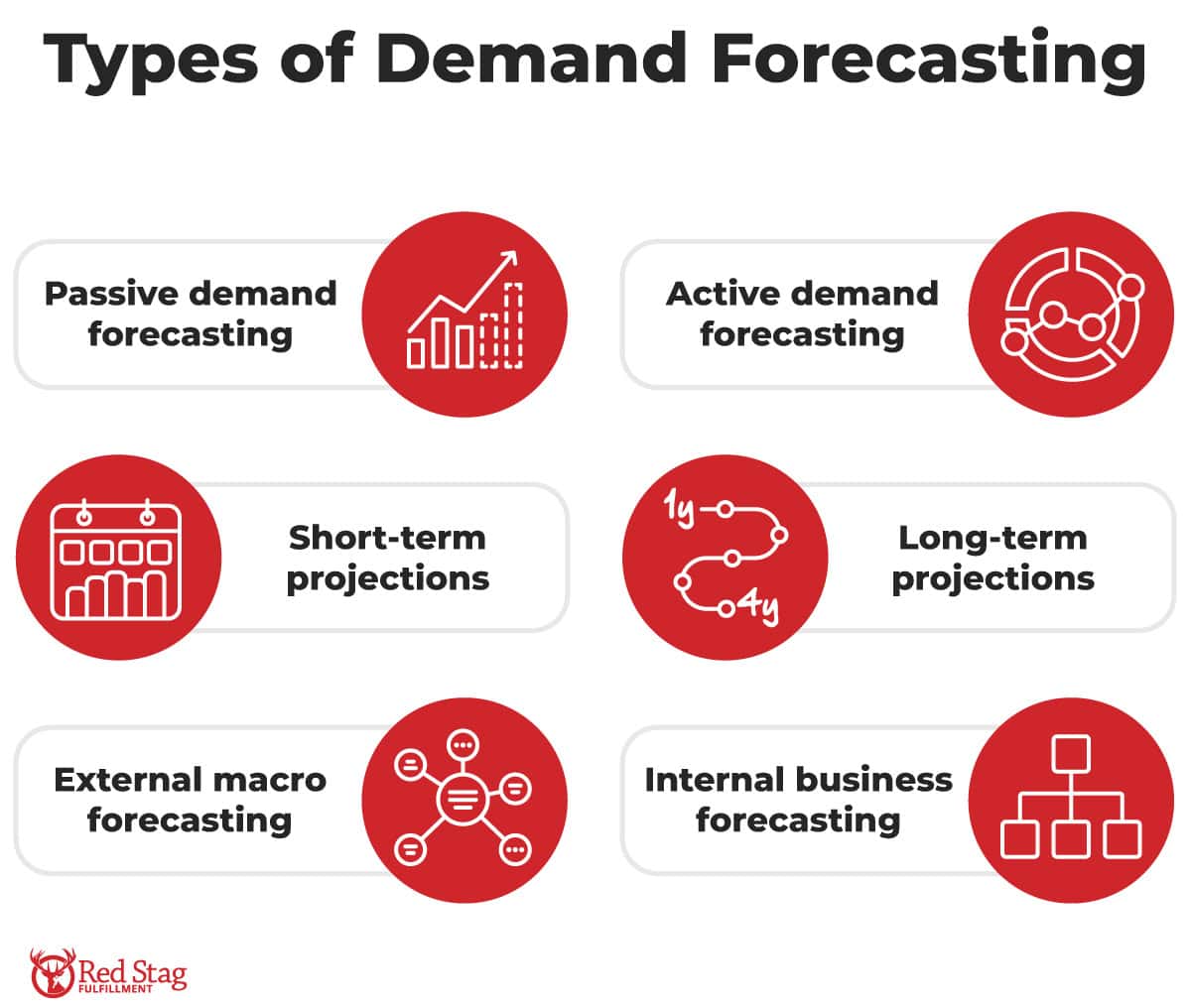

6 types of demand forecasting

There are several methods of demand forecasting. Your forecast may differ based on the demand forecasting models you use.

PRO TIP: The best practice is to do multiple demand forecasts to give you a more well-rounded picture of your future sales. Using more than one forecasting model can also highlight differences in predictions, allowing you to specify your research and find better data inputs.

Here are the 6 types of demand forecasting you can choose from:

1. Passive demand forecasting

Passive demand forecasting uses sales data from the past to predict future demand.

This is the simplest type of demand forecasting, because it doesn’t require you to use statistical methods or study economic trends. This approach assumes that this year’s sales will be approximately the same as last year’s sales.

The passive forecasting model works well if you have solid sales data to build on. This model works best for businesses that prioritize stability over growth.

2. Active demand forecasting

An active forecasting model takes into consideration your market research, marketing campaigns, and expansion plans.

If your business is in a growth phase or if you’re just starting out, active demand forecasting is a good choice to help you make informed decisions.

Active projections often consider external factors, such as:

Economic outlook

Growth projections for your market sector

Projected cost savings from supply chain differences

Startups that have less historical data to draw on will need to base their assumptions on external data.

3. Short-term projections

Short-term demand forecasting only looks at the next three to 12 months.

This type of demand forecasting is useful for managing your just-in-time supply chain. Looking at short-term demand allows you to adjust your projections based on real-time sales data and respond quickly to changes in customer demand.

If you run a product lineup that changes frequently, understanding short-term demand is important. For most businesses, however, a short-term forecast is just one piece of a larger puzzle. You’ll probably want to look further out with medium- or long-term demand forecasting.

4. Long-term projections

Your long-term demand forecast will make projections one to four years into the future.

This forecasting model focuses on shaping your business growth trajectory. While your long-term planning will be based partly on sales data and market research, it is also aspirational.

Think of a long-term demand forecast as a roadmap. Using this forecasting technique, you can plan out your marketing, capital investments, and supply chain operations. That will help you to prepare for future demand. Being ready for your business growth is crucial to making that growth happen.

5. External macro forecasting

External macro forecasting incorporates trends in the broader economy, examines how those trends affect your goals on a macro-level, and gives you direction on how to meet those goals.

Your company may be more invested in stability than expansion, but you still need to consider external market forces to ensure accurate sales projections. External macro forecasts address the availability of raw materials and other factors that directly affect your supply chain.

6. Internal business forecasting

Internal business demand forecasts review your operations to ensure you can meet customer demand and growth goals.

One of the limiting factors for your business growth is internal capacity. If you project that customer demand will double, your enterprise needs to have the capacity to meet that demand.

The internal business forecasting type uncovers limitations that might slow your growth. It can also highlight untapped areas of opportunity within the organization. This forecasting model factors in:

Business financing

Cash on hand

Profit margins

Supply chain operations

Personnel

Internal business demand forecasting is a helpful tool for making realistic projections. It can also point you toward areas where you need to build capacity in order to meet expansion goals.

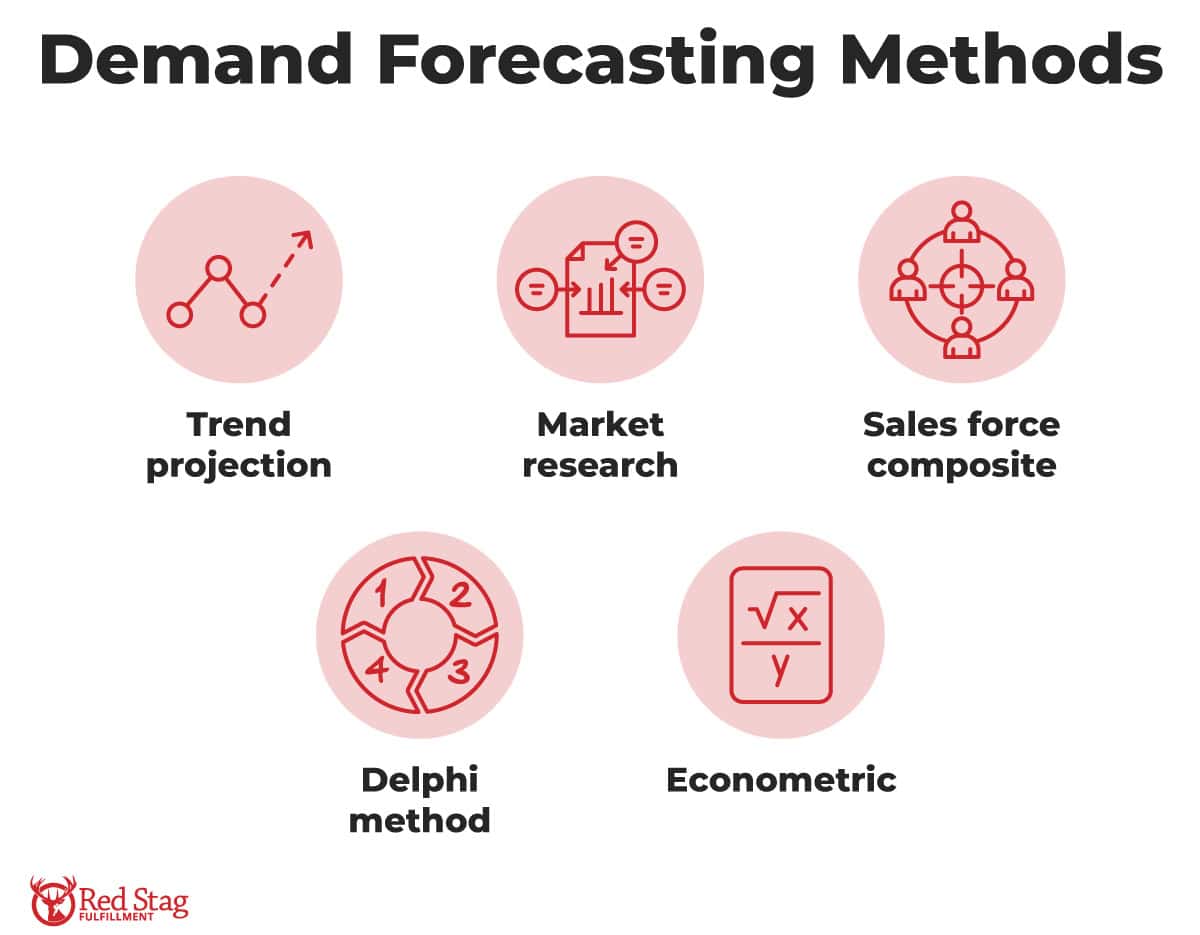

5 demand forecasting methods

There are many different ways to create forecasts. Based on their needs, every enterprise should consider five common demand forecasting methods.

1. Trend projection

Trend projection uses your past sales data to project your future sales.

This is the simplest and most straightforward demand forecasting method.

It’s important to adjust future projections to account for historical anomalies. For example, perhaps you had a sudden spike in demand last year, but it happened after your product was featured on a popular television show, so it is unlikely to repeat. Or maybe your ecommerce site got hacked, causing your sales to plunge. Be sure to note unusual factors in your historical data when you use the trend projection method.

2. Market research

Market research demand forecasting is based on data from customer surveys.

It requires time and effort to send out surveys and tabulate data, but it’s worth it. This method gives you a picture of your typical customer you can’t get from internal sales data.

You can do this research on an ongoing basis or during an intensive research period. Your surveys can collect demographic data that will help you target future marketing efforts. Market research is particularly helpful for young companies that are just getting to know their customers.

3. Sales force composite

The sales force composite demand forecasting method puts your sales team in the driver’s seat. It uses feedback from the sales group to forecast customer demand.

Your salespeople have the closest contact with your customers. They hear feedback and take requests, which makes them a great source of data on customer desires, product trends, and competitor strategies.

This method gathers the sales division with your managers and executives. The group meets to develop the forecast as a team.

4. The Delphi method

The Delphi method, or Delphi technique, is a qualitative method of demand forecasting that leverages expert opinions on your market forecast.

This method requires engaging outside experts and a skilled facilitator. To complete the Delphi method, follow these steps:

01

Send a questionnaire to a group of demand forecasting experts.

02

Create a summary of the responses from the first round.

03

Share the results with your panel.

04

Repeat the process through successive rounds.

The answers from each round, shared anonymously, influence the next set of responses. The Delphi method is complete when the group comes to a consensus. This demand forecasting method allows you to draw on the knowledge of people with different areas of expertise.

NOTE: The anonymous responses allow each person to provide frank answers. Because there is no in-person discussion, you can include experts from anywhere in the world on your panel, and the process allows the group to build on each other’s knowledge and opinions, resulting in an informed consensus.

5. Econometric

The econometric method is a quantitative type of forecasting that combines sales data with information on outside forces that affect demand.

You use this combination of data to create a mathematical formula that predicts future demand.

The econometric demand forecasting method accounts for relationships between economic factors. For example, an increase in personal debt levels might coincide with an increased demand for home repair services.

An expert’s guidance on combining demand forecasting methods

The best way to effectively employ demand forecasting methods is to use a combination of methods and continually evaluate the results.

As Arthur Pentecoste, data scientist and author of Demand Prediction in Retail says:

To obtain the most accurate forecasts you’ll want to combine them.

Common methods include: blending all available data as inputs of a single forecasting model (e.g., historical sales, marketing trends, customer survey, economic metrics…) or using several models and consider the average of the different results as your demand forecast.

In any case, the best way to select a method will be to apply it to historical data and compare results.

Arthur Pentecoste

Data scientist and author of Demand Prediction in Retail

Demand forecasting examples

All types of businesses can benefit from demand forecasting. Here are three examples of how demand forecasting might work for an ecommerce company.

Passive/Trend projection

The situation: A husband and wife team sells costumes, party favors, and decorations for kids. They have been in business for more than 10 years, and have built their business to a comfortable level of revenue and profitability. While they don’t plan to retire soon, they also don’t plan to expand.

They average the last three years of sales data and use that to project trends for the coming year. Historical data tells them that their best months are May and October, and the worst are December and August. They use this information to create a trend projection that tells them when they need to place their wholesale orders.

This data also tells them when they need to add temporary staff at their fulfillment warehouse. They factor in a plan for a summer promotion in the coming year that should increase sales.

Active/Market research

The situation: A startup has developed revolutionary wireless headphones. The company initially launched through Kickstarter. The crowdfunding platform gave them some information about customer demand.

Now, they need to expand their customer base to grow their enterprise into a sustainable ecommerce business.

The marketing team sends surveys to all customers. From the responses, they develop a profile of the company’s current customers. The profile includes age, income, employment, and where they live. They discover that people who commute by public transit are enthusiastic about their noise-canceling headphones.

From the survey responses, the company develops a marketing plan that includes ads on trains and buses. They bring in econometric principles to project the impact of their marketing campaign on future sales. From data they gather on demographics and consumer behavior, they are able to develop a demand forecast.

Short-term/Sales force composite

The situation: A company sells high-end office chairs, both B2C and B2B. The sales team works primarily with B2B customers to generate large orders for corporate offices. However, the salespeople have had a hard time closing sales for the past quarter.

The CFO convenes the sales group to brainstorm. When the salespeople compare the feedback they have gotten, they uncover a market trend — more people are working from home. Companies are reducing the amount of office space they need to furnish, and corporate clients no longer view office amenities as a way to lure new hires.

The company created a short-term demand forecast with greatly reduced sales over the following six-month period. It scaled back its production accordingly. This approach would give the company a period of time to revamp its marketing approach to meet changing customer demand. In the meantime, it could use other demand forecasting techniques to develop projections for its new markets.

Predictive Analysis (Historical Data)

Dr. Bob Wood, Professor of Finance at University of South Alabama, cites a couple of examples of using predictive analysis of historical data to determine demand:

I worked with a local HVAC/plumbing/electrical firm that used predictive analysis (historical data) and customer service experiences gleaned from company service technicians’ customer interactions to estimate future service needs.

Their experience has shown that using both of these methods has provided valuable service staffing level estimations and customer appointment time preferences.

Another client has both traditional and online retailing operations. The online presence is relatively new so we were unable to use historical data.

As an alternative, we used in-store and website customer surveys to rank order online purchasing preferences (free shipping and free returns dominated other preferences) to estimate online purchasing demand.

Dr. Bob Wood

Professor of Finance at University of South Alabama

Why your ecommerce company needs demand forecasting

Whether your ecommerce business is small or large, demand forecasting is essential.

A demand forecast can be as simple as an Excel spreadsheet detailing your cash flow for the past 12 months, or as complex as using statistical methods of regression analysis to study the influence of economic trends on your future business. Even the most basic forecast will give you vital information.

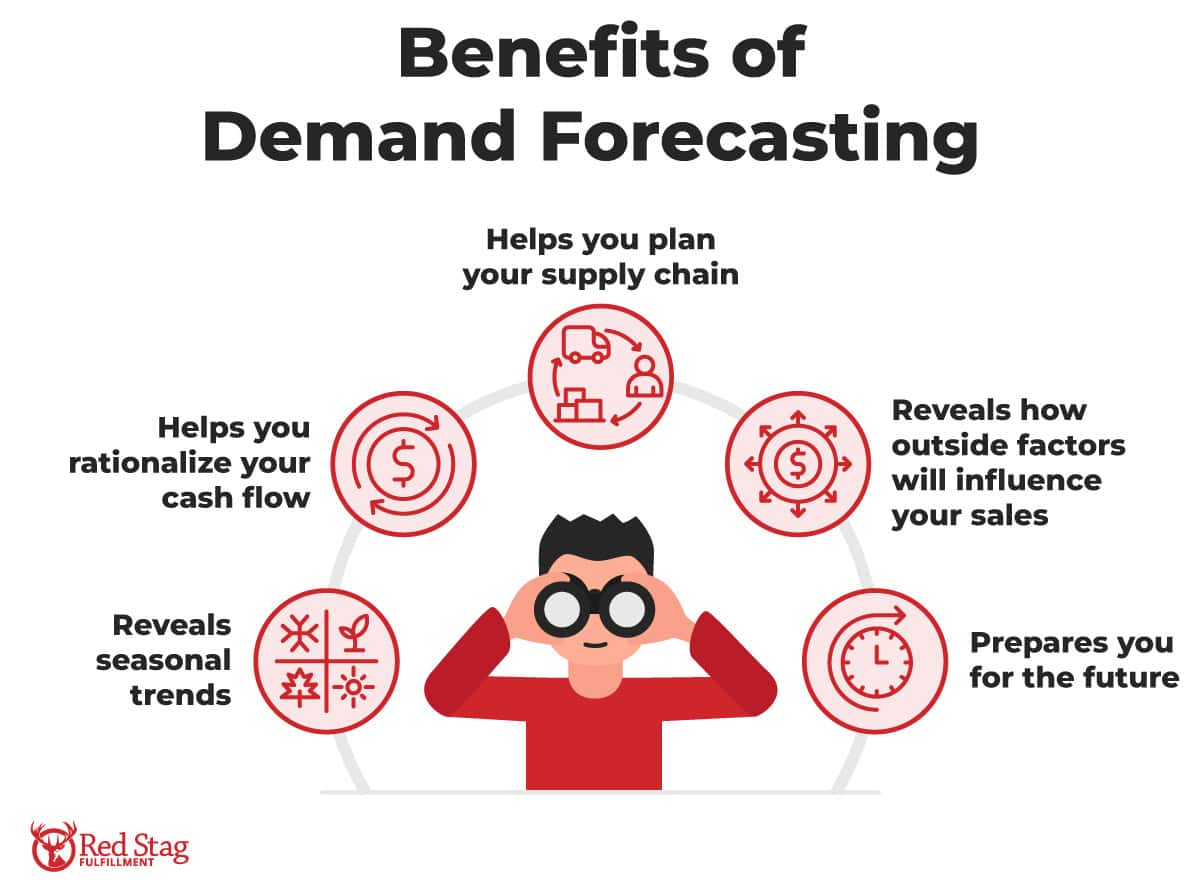

Here are just a few of the benefits that demand forecasting can provide:

- Reveals seasonal trends.

A review of historical sales data will reveal seasonal fluctuations to inform your sales forecasting. Beyond busy holiday seasons, it’s also important to know which months have less customer demand. If your sales take a dip every February, that could be a good time to offer discounts to engage customers. - Helps you rationalize your cash flow.

Your past balance sheet will show you how sales revenue meshes with costs of goods sold. This data can show you when you will have the cash on hand to keep inventory levels where they need to be. - Helps you plan your supply chain.

Demand forecasting will help you with capacity and inventory planning so you can have inventory on hand when customer demand spikes. This strategy will keep you from incurring rush charges and putting items on backorder as you scramble to fill orders. - Reveals how outside factors will influence your sales.

Forecasts can include data about industry trends, the state of the economy, and projections for your market sector. Bringing these factors into your forecasting model can help you be ready to adapt and grow your business. - Prepares you for the future.

Every business has to be ready to weather the unexpected, whether it’s a natural disaster or a new competitor that eats into your market share. Demand forecasting prepares your supply chain and business for future shocks.

Issues with demand forecasting in most companies

Before you can master effective demand forecasting, you need accurate information. Issues with demand forecasting in most companies have to do with missing data. Here are some factors that can get in the way of your forecasts:

- Lack of historical sales data.

This problem commonly arises for companies without much of a track record, but, even more established businesses can struggle. Compile and organize sales data from past years into a format that’s easy to use. - Inadequate supply chain management.

The best demand forecast won’t help you if your supply chain isn’t predictable and well-managed. You need to know the exact lead time series required for the allocation of raw materials, to produce finished goods, and to ship them to your order fulfillment warehouse. - Lack of inventory control.

Good inventory management is the foundation of good demand planning. If you don’t have a handle on what you have in the warehouse, you can over- or underestimate your production. Fortunately, your 3PL services provider can help you with that.

Demand forecasting best practices

You don’t have to fall prey to the pitfalls of demand forecasting. These best practices for supply chain operations can help you use demand forecasting to keep your business healthy.

- Share data up your supply chain.

Data silos create inefficiency. Keep communication lines open with every level of your supply chain and make sure information flows in both directions. - Use redundant sourcing.

Relying on one supplier can lead to backlogs if that supplier has a production problem. Diversify your sources to protect your supply chain. - Track the results of your demand forecasts.

Revisit past forecasts to learn from your mistakes. How accurate was your last forecast? Did your demand forecasting techniques work well? Or do you need to look to different models for actionable results? - Leverage your 3PL to avoid dead stock.

Dead stock consists of items that never sell. This merchandise can linger on warehouse shelves for years, costing you money without bringing in revenue. Your eCommerce fulfillment company (or 3PL) can help you avoid dead stock with transparent inventory.

NOTE: Your fulfillment company is an important partner as you forecast demand. It can aggregate many of the data points you need for accurate demand forecasting.

Demand forecasting drives smarter business decision-making. Whether you choose simple or more complex methods, demand planning based on sales data, market research, and economic factors will help your business stay strong.

Demand Forecasting FAQ

Here are the answers to some additional questions you might have about demand forecasting:

What are the different methods of demand forecasting?

The five most popular demand forecasting methods are:

Trend projection

Market research

Sales force composite

Delphi method

Econometric

What are the types of demand forecasting?

There are six types of demand forecasting, which include:

Passive demand forecasting

Active demand forecasting

Short-term projections

Long-term projections

External macro forecasting

Internal business forecasting

Why is demand forecasting important in supply chain?

Demand forecasting in supply chains refers to the same process of estimating future demand for products or services. Demand forecasting is particularly important in supply chain-related businesses because it plays a critical role in managing inventory, knowing when to restock products, and capacity planning.