Dock-to-dock shipping is a useful shipping strategy in which deliveries travel directly between two docks without being handled, transferred, or stored in between.

When intermediaries are involved in a delivery, handling costs grow, and the risk of transit delays or damages increases. A dock-to-dock shipping strategy helps you mitigate these challenges by eliminating the need for in-transit interference.

This article will help you understand the definition, benefits, and key considerations of dock-to-dock shipping.

What does dock to dock mean?

Dock to dock refers to a shipping method where goods are collected from one loading dock and delivered directly to another loading dock, without any intermediate stops, transfers, or handling. This approach helps minimize transportation times and reduce the risk of goods being damaged, delayed, or lost in transit.

When speaking about dock-to-dock shipping services, the loading dock is referred to as the ‘origin’ and the unloading dock is known as the ‘destination’.

A dock-to-dock shipping strategy is especially useful for:

Time-sensitive or expedited shipments

Goods with strict delivery requirements

Vulnerable or fragile goods

In a dock-to-dock service, goods are loaded and unloaded at designated docks. These docks are usually supported by ramps, forklifts, and other specialized equipment that facilitates the efficient transfer of goods between delivery vehicles and storage facilities.

Dock to dock vs cross-docking

In logistics, cross-docking and dock to dock are both strategies for optimizing the transportation of goods between two loading docks.

However, cross-docking refers to the process of transporting items directly from an inbound dock to an outbound dock at the same distribution center, while dock to dock involves transporting goods directly between two docks at different facilities.

Supply chain benefits of a dock-to-dock shipping strategy

Dock-to-dock shipping can be highly advantageous for companies seeking to improve the efficiency and speed of deliveries without employing more staff. It’s also an easy way to reduce the risk of goods being mishandled or lost during transit

Here are five clear benefits of dock-to-dock shipping:

- Reduced transit times.

Dock-to-dock shipments are not handled nor subjected to multiple stops between loading docks, meaning they arrive at the destination dock faster. - Fewer handling costs.

Because dock-to-dock shipments do not require intermediary checks or handling, your associated labor costs are reduced. - Minimized shipment risk.

Items are not moved or handled between delivery points, lowering the risk of goods being damaged or lost in transit. - Environmentally friendly.

A dock-to-dock strategy produces a lower carbon footprint compared with shipments that travel extra miles to various transfer destinations. - Simplifies logistics.

The logistics process for dock-to-dock shipments is much easier to manage since there are fewer steps and intermediaries required to get goods from Point A to Point B.

A recent report by the Chief Business Economist at S&P Global highlighted a sharp increase in shipping delays and shipping rates since an initial 2023 post-pandemic recovery. While we’re still much better off than we were at the peak of COVID-19, expedited shipping strategies such as dock to dock are a powerful way to counter these rising costs and ongoing supply chain disruptions.

Dock to dock examples and use cases

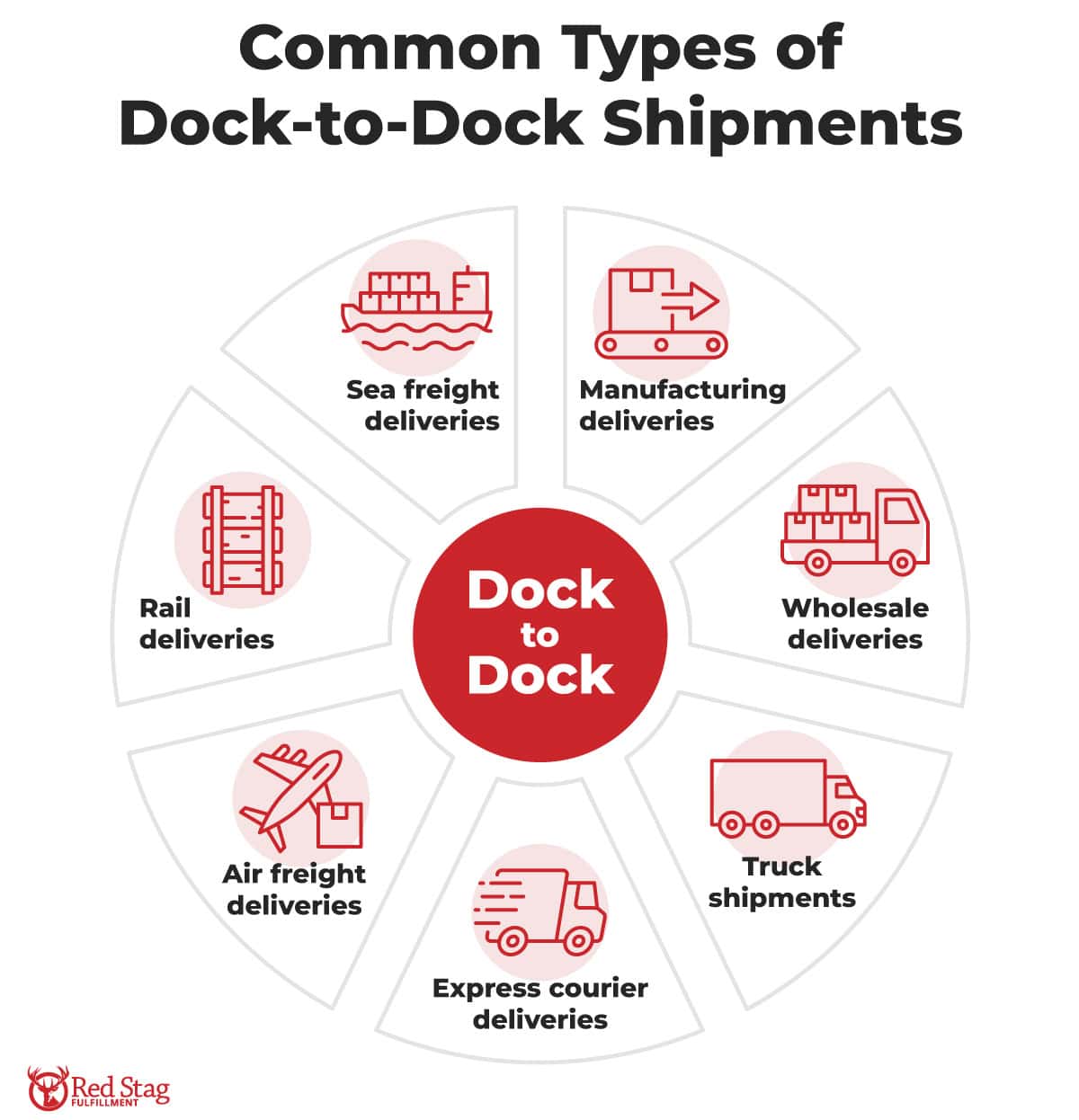

Dock to dock is used across many business sectors and transportation models, from delivering manufactured goods to retailers and wholesalers to ensuring efficient transportation of products between international warehouses.

Common types of dock-to-dock shipments include:

Manufacturing deliveries

Wholesale deliveries

Truck shipments

Express courier deliveries

Air freight deliveries

Rail deliveries

Sea freight deliveries

In some cases, a dock-to-dock shipment may not live up to its name in the literal sense.

For example, air freight and sea freight deliveries may require unloading and reloading at a port to be inspected by customs officials. But for land-based local deliveries, a dock-to-dock shipment will usually remain on the original delivery vehicle until it reaches the destination dock.

Considerations for implementing a dock-to-dock strategy

For dock to dock to be effective, it needs to fit into your budget and be supported by the correct infrastructure at both ends of the delivery. Let’s dive a little deeper into some core considerations for dock-to-dock shipping.

Risks

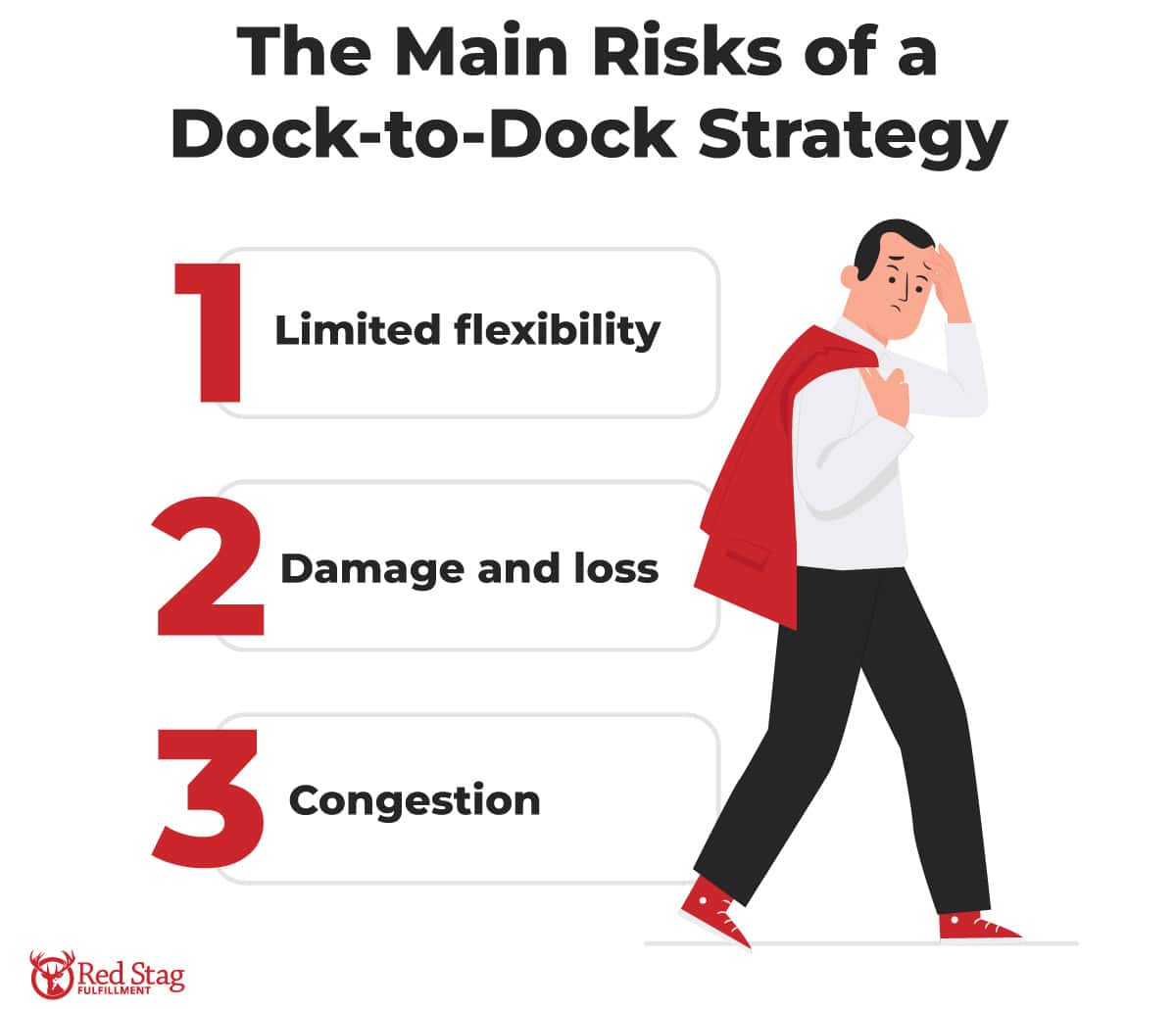

Despite negating many of the dangers involved in shipping goods between locations, dock to dock is not without its own hazards and risks.

The main risks of a dock-to-dock strategy include:

- Limited flexibility.

Goods can only be delivered to locations equipped with the correct infrastructure, which may mean requiring last-mile delivery to reach the final destination. - Damage and loss.

Although they reduce the risk of goods being damaged or lost during transit, loading docks are high-traffic areas that make it easier for goods to be damaged or stolen. - Congestion.

If deliveries aren’t timed right, you run the risk of transport vehicles queuing up to use the same dock—resulting in operational delays and frustrated carriers.

PRO TIP: You should also consider any compliance or liability concerns that come with dock-to-dock transportation, such as customs clearance requirements. Clear operating procedures and carrier contracts are essential for avoiding fines and understanding exactly who is responsible for damaged or lost goods.

Costs

Whether a dock-to-dock shipping strategy suits your business will be largely determined by how it fits into your budget. It’s crucial you understand and try to calculate all the associated costs before deciding if it’s right for you.

Common dock-to-dock costs to account for:

Specialized equipment costs for unloading large or heavy goods

Dock infrastructure set-up and maintenance costs

Last-mile delivery costs if the unloading dock is not the final destination

Insurance fees and overhead costs

Specialized packaging costs, such as pallets and crates

Transit times for dock-to-dock shipments

Understanding average transit times will help you better plan and commission dock-to-dock shipments. These times will vary depending on factors such as the distance between docks, mode of transportation, and customs clearance complexity.

PRO TIP: Begin by researching standard transit times for your shipping method to get a rough idea of what to expect. Then measure and report on average dock-to-dock transit times once your strategy is up and running to establish a more accurate number for your budget.

Facility and equipment requirements for dock-to-dock operations

You may need to invest in new equipment and infrastructure to support dock operations.

For example, a loading dock will need to be installed at both ends of the transportation route if none presently exist. Similarly, a company shipping heavy goods may need to invest in forklifts or gantry cranes to load and unload dock-to-dock shipments.

Pricing your dock-to-dock shipments

If offering dock-to-dock shipping as a specialty service, it’s good practice to have a plan for how you price this service. Since dock to dock is typically faster than regular shipping methods, you may wish to include a premium to reflect the added value.

Factors to consider when pricing dock-to-dock shipments:

01

Dimensions, volume, and weight of the shipment

02

Origin and destination docks

03

Type of goods and special handling requirements

05

Insurance and other overhead costs

PRO TIP: It can be prudent to also consider less-obvious costs, such as profit reduction for smaller shipments compared with bulk shipments, and factor these into your total pricing.

How Red Stag Fulfillment can optimize your shipping process

At Red Stag Fulfillment, we help hundreds of businesses meet customer expectations and deliver goods promptly through our robust shipping infrastructure and years of dedicated experience. Our warehouses are specifically designed to handle and ship goods in the most efficient method possible—particularly goods that are time-sensitive, large, or bulky.

Ready to stop worrying about your order fulfillment? Reach out to us today.