Inventory replenishment, also called stock replenishment, isn’t just for retail establishments. It is also a vital part of ecommerce fulfillment and inventory management. Developing an inventory replenishment plan will save you money, increase your profitability, and improve your sell-through. Here’s what you need to know to get started.

TL;DR:

Inventory replenishment essentials

Effective inventory replenishment is crucial for eCommerce success, ensuring products are always available to ship when orders come in.

Supply chain optimization improves inventory management through better visibility and communication between all partners.

Key strategies include inventory forecasting, economic order quantity (EOQ), demand forecasting, and ABC analysis.

Partnering with a quality 3PL adds expertise and additional data for more effective inventory planning.

What is inventory replenishment in eCommerce?

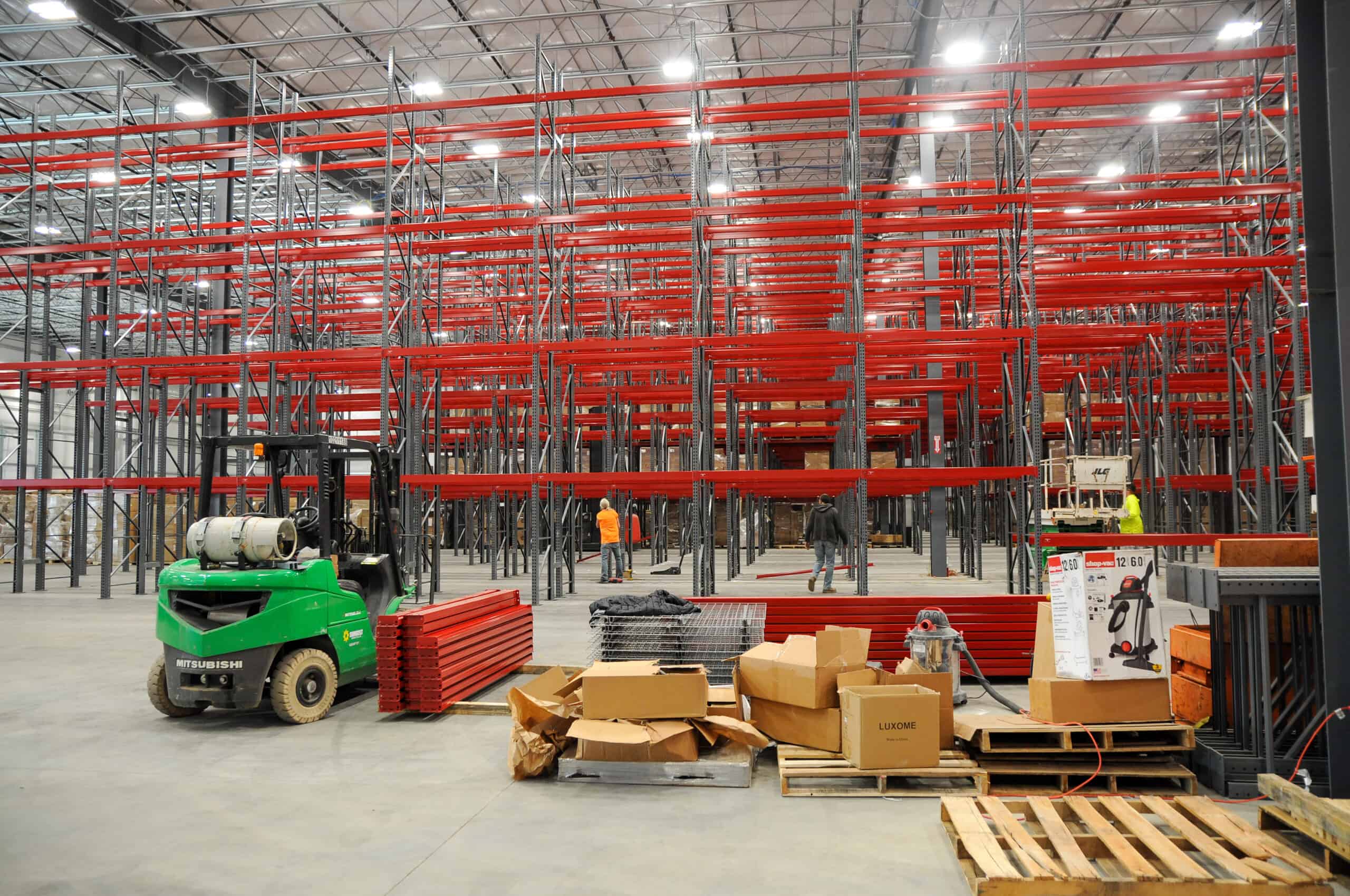

Inventory replenishment in eCommerce is the strategic practice of maintaining optimal stock levels at your fulfillment warehouses to ensure you always have inventory available to fulfill customer orders without excessive overstock. It involves tracking key metrics like reorder points, lead times, and safety stock levels to balance inventory investment with order fulfillment capabilities.

Inventory replenishment in retail is the practice of keeping back stock in storage to fill the shelves when products run low. ECommerce inventory replenishment is your plan for timely stock replenishment at your fulfillment warehouses, so you always have inventory to fill orders.

Stock replenishment for eCommerce involves your whole supply chain. Successful inventory replenishment strategies consider several inventory management data points. Your reorder levels, lead time calculations, and safety stock levels are among the metrics that will guide your inventory replenishment plan.

Why stock replenishment is important in eCommerce

For a go-getter with a focus on reaching more consumers with your marketing and expanding your customer base, stock replenishment may sound uninteresting and unimportant. However, product rankings and sales growth don’t rest solely on your marketing plan. Customer satisfaction, the lifeblood of every eCommerce business, depends on fast, accurate order fulfillment.

Inventory replenishment planning ensures that your products are on warehouse shelves and ready to ship when orders come in. If your most popular products are backordered, you could lose customers to your competitors.

ALERT: According to research, 70% of online shoppers will look elsewhere if your product is out of stock, and 37% will never return to your site. Poor inventory management directly impacts customer lifetime value and can destroy brand loyalty that took years to build.

Optimize your supply chain to improve inventory management

Optimizing your supply chain is a great place to begin when you want to improve inventory management. For starters, open communications channels between your raw materials suppliers, manufacturing operations, and 3PL services company. End-to-end supply chain visibility is essential to your inventory replenishment strategy. Sharing knowledge among different departments as well as outsourced operations adds immense value to your supply chain.

When you have collaborative systems in place, you can lean on your partners to help you deal with production and fulfillment challenges. Visibility into the processes of each component of your operations will help you anticipate potential problems and develop strategies to mitigate supply chain disruptions.

For example, when COVID-19 led to a holiday season with reduced carrier capacity, Red Stag Fulfillment immediately started talking to transport providers and its clients. This proactive strategizing helped Red Stag ship its clients’ holiday orders with almost no delays.

PRO TIP: Implement a regular cadence of supply chain meetings that include representatives from your suppliers, manufacturers, and 3PL providers. These collaborative sessions can identify potential bottlenecks before they impact your replenishment cycle and lead to creative solutions that a siloed approach might miss.

Best practices to develop your inventory replenishment strategy

There are many different methods to help you with inventory management and forecasting demand. Using these tested systems will ensure you have enough stock to meet demand. They will keep you from holding so much inventory that you eat into your profitability.

Here are five popular inventory management techniques that will help you improve your inventory replenishment strategy. You don’t have to pick just one; these methods work well in combination and along with other inventory management strategies.

Inventory forecasting

Inventory forecasting is the general term for projecting future demand and making an inventory replenishment plan to provide optimal inventory levels to fill your orders. These forecasts consider many factors, including:

Lead time: The amount of time it takes to receive inventory once you place an order.

Seasonality: Differences in demand during different seasons.

Past sales: Use sales data from previous seasons to project future demand.

Using these and other data points that help you understand your supply chain, you can set your reorder point. The reorder point comes when you have enough inventory left to last for your reorder lead time. Your inventory replenishment strategy will hinge on setting reorder points with as much accuracy as possible.

You will also want to set safety stock levels. This is additional inventory to keep on hand in case of supply chain disruptions that extend your lead time.

Setting up a system for inventory forecasting doesn’t have to be a lot of work. Many software apps can help you collect and analyze the data you need to make a meaningful forecast.

Economic order quantity

Economic order quantity, or EOQ, is a formula for projecting the amount of stock you’ll need during the following year. The formula looks like this:

Economic Order Quantity Formula:

EOQ = square root of (2 × Demand rate (annual sales) × Annual ordering cost) ÷ (holding cost)

Economic order quantity adds a cost/benefit analysis to your inventory replenishment plan. The formula helps you understand the carrying costs of storing inventory. It shows how buying ahead, while it might seem like a good replenishment strategy, can be costly. EOQ calculates the costs of holding excess stock.

Passive demand forecasting

Demand forecasting is an element of inventory planning and forecasting. There are many different types of demand forecasts and several methods for creating a demand forecast.

Passive demand forecasting is simple and relatively easy. In the passive model, you take sales data from past years and project that into the future. If your company is established and demand for your products is stable, passive forecasting can work well. However, if your business is growing or you don’t have much sales data to project from, you might need a different approach.

Active demand forecasting

Active demand forecasting relies on more than past sales. This demand forecasting model uses many factors, including projected sales from future marketing campaigns. Active forecasting also considers external factors such as projected growth in your market sector or the economy as a whole.

PASSIVE FORECASTING:

Simple to implement

Low cost to maintain

Works well for established products

ACTIVE FORECASTING:

Incorporates marketing initiatives

Considers market trends

Better for growing businesses

ABC analysis

An ABC analysis can help guide your inventory replenishment plan by showing you which products need the most safety stock and highest reorder points. You classify your products as:

A: Your top sellers or signature products, essential to the success of your business.

B: Important but not crucial products.

C: Minor or peripheral items in your product line. These are products such as replacement parts that don’t sell well but need to stay in your product line.

Your inventory replenishment planning should focus on your A products, where the stakes are highest if you run out of stock. Ensure your A supply chain is running smoothly, from raw materials to customer delivery, and the rest will fall into place.

Key Takeaway: The ABC analysis follows the Pareto principle: typically, 20% of your products (Category A) will generate 80% of your revenue. Prioritize your inventory management resources accordingly, ensuring your Category A items never run out of stock while maintaining reasonable reorder points for B and C items.

Include your 3PL in your inventory replenishment planning

Your fulfillment company can do more than ship your orders and make your customers happy. A 3PL is an excellent inventory replenishment partner. After all, fulfillment centers deal with replenishment issues every day.

Ask your fulfillment partner for help and advice as you create your replenishment plan. Have your 3PL share data to help you make accurate demand forecasts, and share your forecasting to help them plan for the space you need in the year ahead. You don’t have to come up with solutions to your inventory replenishment challenges on your own; your 3PL is part of your team.

At Red Stag Fulfillment, we like to help our clients with inventory management. A well-crafted replenishment plan helps us keep your products moving through our warehouses. Plus, we want to help you keep the right amount of stock on hand to fill every order the day it comes in, using our same-day fulfillment guarantee.

Frequently asked questions

What is the difference between inventory management and inventory replenishment?

Inventory management is the broader discipline that encompasses tracking, storing, and organizing your entire inventory. Inventory replenishment is a specific component of inventory management that focuses on the strategic process of restocking products to maintain optimal inventory levels. While inventory management includes everything from receiving to warehouse organization to fulfillment, replenishment specifically addresses when and how much to reorder.

How can a 3PL help with inventory replenishment?

A quality 3PL partner can significantly improve your inventory replenishment process by providing real-time inventory data, advanced warehouse management systems, and expertise in forecasting. They can alert you when inventory reaches reorder points, share insights on seasonal trends they observe across clients, and optimize warehouse space to accommodate your replenishment needs. Additionally, 3PLs with multiple fulfillment centers can help you strategically distribute inventory to reduce shipping costs and delivery times.

Optimize your inventory management with expert help

Red Stag Fulfillment can help you develop and implement an effective inventory replenishment strategy that keeps your products in stock without tying up excess capital. Our fulfillment experts work with you to analyze your sales patterns, optimize your reorder points, and ensure you never miss a sale due to stockouts.

Talk With Us