Innovative eCommerce fulfillment providers have been looking for better ways to measure and charge for warehouse storage. A volumetric storage model accurately measures the space your goods actually use, so the industry is moving toward this more precise method for determining client storage needs.

Volumetric storage definition

Volumetric storage calculates storage charges by the average volume of goods stored, measured in cubic feet. For example, let’s suppose Acme Corp. sells products in 12x12x12 boxes. Every unit the company stores in a 3PL warehouse uses a cubic foot of volumetric storage.

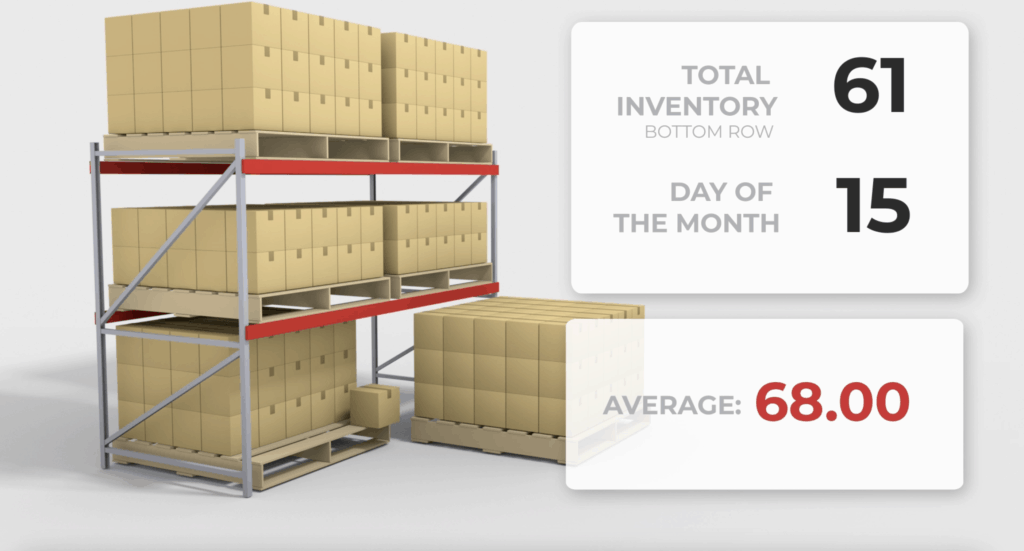

At the beginning of the month, Acme Corp. has 100 units in the warehouse. It sells nothing the first 10 days, then it sells 20 units on the 10th and 20th days of the month, leaving 60 units at the end of the month, so its volumetric storage goes down by 10 cubic feet per day.

Here’s how the warehouse will calculate volumetric storage:

(100 cu ft x 10 days) + (80 cu ft x 10 days) + (60 cu ft x 10 days) = 2400 cu ft/30 days = 80 cu ft average

The Acme Company will be charged for 80 cubic feet of storage this month. Warehouse management software that records the number of units in the warehouse each day and calculates their volume allows your 3PL to charge you for the precise volume of inventory space you use each month.

More about the cubic storage model.

Benefits of a volumetric inventory model in fulfillment warehousing

In the past, most fulfillment centers charged for storage by the pallet. However, that model has flaws that lead to inexact storage charges and potentially increase inventory shrinkage.

Here are some benefits of the volumetric model for calculating fulfillment warehouse inventory.

More accurate than pallet storage

Under the pallet storage model, you were charged for the number of pallets of goods you stored during the month. It didn’t matter how many or how few units each pallet held — the charge was the same.

But pallets come in various sizes, so you might have different assumptions than the warehouse about the number of pallets, leading to unpleasant surprises on your bill. For instance, if you send products on pallets larger than the standard size used to calculate storage costs at a specific 3PL, the warehouse might divide one pallet into two, doubling your storage costs.

Pay only for product storage, not for the airspace above your merchandise

The pallet model also doesn’t accurately reflect sales velocity or reward your business for agile inventory management. If most, but not all, the SKUs on a pallet sell early in the month, you might be paying for airspace above the pallet. The volumetric storage model charges you for the volume of storage you actually need, not the volume of space above an arbitrary and inconsistent metric (the pallet).

Prevent warehouse damage

One of the downsides of the pallet storage model is that it encouraged companies to game the system by overloading pallets. If you pay by the pallet, the logic of that makes sense. However, piling pallets with more goods than they’re meant to hold is an invitation to damage.

On an overstuffed pallet, units on the bottom can get crushed under the extra weight, and units piled too high on top are more susceptible to damage during transit. In an effort to save money on storage, eCommerce companies lost money on inventory.

Benefit from inventory velocity and agile inventory management

The best way to keep storage costs low is to develop a robust, evidence-based inventory management strategy. With a well-managed supply chain and agile inventory management, you can keep the minimum amount of stock on hand necessary to meet demand.

The volumetric storage model rewards you for your excellent inventory planning with lower storage costs. Even better, you don’t tie up capital in excess inventory, keeping your cash flow healthy.

Simplify inventory storage

The pallet storage model puts the burden on brands to optimize their warehouse storage space by palletizing correctly. With no way to know or understand the storage methods of your fulfillment warehouse, you needed to deliver the perfect pallet loads for storage to minimize your costs while fitting into the 3PL’s storage scheme.

The volumetric storage method simplifies storage by taking the burden off you. You pay for the amount of product you have in the warehouse by volume, period.

Red Stag Fulfillment: Trusted warehousing partner

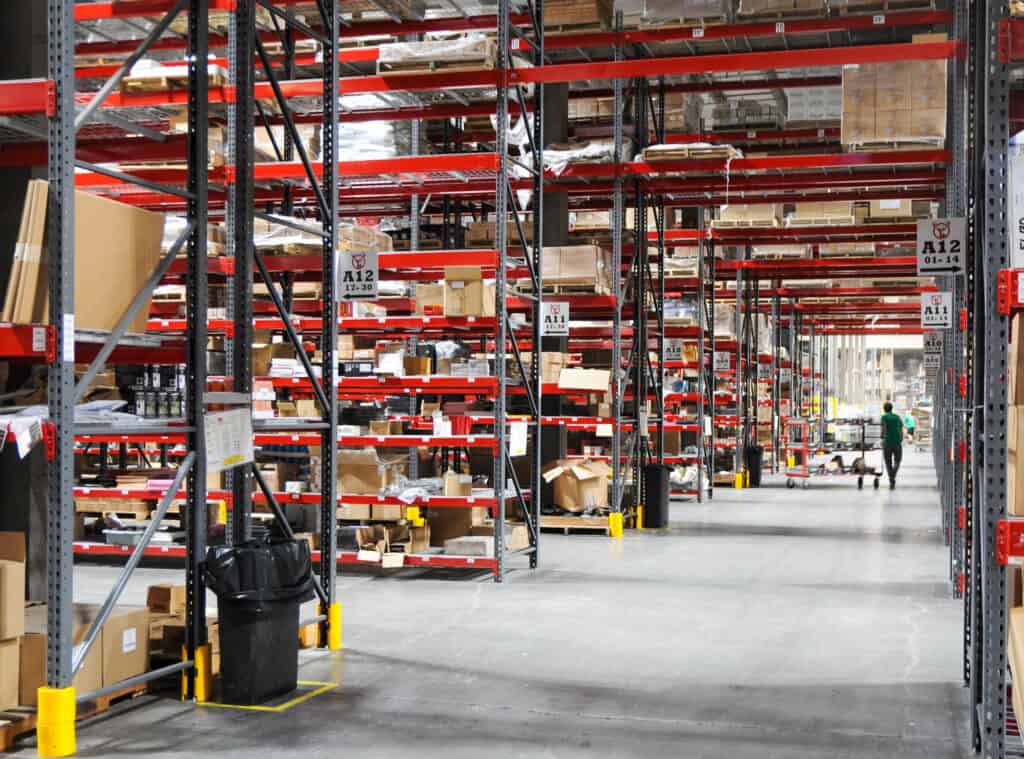

Red Stag Fulfillment is one of the industry’s most trusted strategic logistics partners. Our state-of-the-art volumetric storage model is only one reason. We also offer:

- Same-day fulfillment: We can ship orders the day your customer places them.

- Two-day shipping: Our fulfillment warehouses in Utah and Tennessee can reach 96% of U.S. households in two days or less via regular ground shipping.

- Zero shrinkage allowance: We treat your products with the same care as if they were our own. We pay you the replacement cost if we lose or damage any merchandise. Unlike many fulfillment companies, we have zero allowance for shrinkage.

- Inventory accuracy: In 2021 (the most recent year for which we have data), our inventory accuracy rate was 99.991%, well above the industry average.

- Fulfillment guarantees: Red Stag doesn’t just promise high levels of service; we back it up with order fulfillment guarantees. If we ship an order late, we pay you $50. If we make an error in fulfillment, we fix the problem and pay you $50. Best of all, our error rates are so low that we rarely pay our clients $50. You get fast, reliable fulfillment every time.

“Using volumetric storage puts the responsibility of optimizing space utilization on Red Stag Fulfillment. In other words, if we are inefficient in how we store product (don’t fully utilize a pallet location), that doesn’t negatively impact the client. You pay the same regardless of how or where we store it.” – Tony Runyan, VP of Client Relations, Red Stag Fulfillment

Great fulfillment is the secret sauce of successful eCommerce brands. If you’re ready to grow your business, give Red Stag Fulfillment a call.

More about storage: