A vital part of your business is its inventory. Having too or too little of your inventory could make or break your business’ sales. This is where inventory management comes into play. By managing your inventory, you can make sure your business is properly stocked with the products or materials it needs. But, what is inventory management exactly?

Definition of Inventory Management

The definition of inventory management is the process of ordering, storing, using, and selling a company’s inventory. Inventory management is a method to keep track of your inventory. Essentially, inventory management tracks your products from once they arrive at the warehouse to its purchasing journey.

By actively managing your inventory, you are able to see trends when they happen to ensure your inventory is well-stocked. Let’s say you own a workout supplement company, and you notice that your protein mix is selling fast. By tracking your inventory, you can see customer trends in real time. Thus, making you increase your protein mix supply to match customer buying trends.

On the other side of things, inventory management will allow you to see where there will be shortages — giving you plenty of warning. Let’s use the same example from before. If you noticed that your protein mix is flying off the shelves and your next delivery isn’t until next month, you have plenty of time to tell your customers of the shortage. Methods like customizing your website and email communication are great ways to communicate delays and shortages to your customers.

How it works

Before you can improve your inventory management, you need to know how it works. For bigger businesses, inventory management is maintained by the warehouse they use. Small businesses might choose to track inventory themselves or work with a 3PL that scales with their growth. The difference is the technology you might use. Warehouses will use inventory management softwares to ensure the most accurate inventory levels and locations within the facility. How? The software tracks the movement of each product from dropoff of goods from the supplier to packing and shipping. The same thing can go for small businesses that opt to track inventory themselves. However, it will be manually counted and tracked.

Inventory Management Methods

Based off your decision mentioned before, you might opt to either work through an inventory management software or manually enter your inventory information. But, it’s important to find the right inventory management method for your business. From just-in-time (JIT) to first-in-first-out (FIFO), here are a few inventory management methods that can help you make your decision:

Just-In-Time Inventory Management (JIT)

Just-in-time inventory management is essentially what it sounds like. For this management method, you essentially keep the bare minimum of your inventory on hand. And when you run out, you simply place the next order. This method ensures that your business doesn’t over order products and potentially run into additional storage costs. It also allows for your business to reduce their storage costs and keep their inventory fresh.

Days Sales in Inventory (DSI)

Days sales in inventory is the average time it takes a business to turn its inventory into sales. DSI is a formula that can help businesses figure out how long their inventory will last as well as how long it takes inventory to turn into a sale. By calculating this formula, you are able to find out your inventory’s turnover rate. This can help your company manage inventory properly by finding out when you should order your products to keep up with buying trends.

Here’s how to calculate the DSI formula:

DSI = (inventory/cost of sales) x (# of days in the period)

Cross-Docking

Cross-docking is considered a form of the JIT method. However, it differs by eliminating storage completely. Cross-docking is a method of unloading inbound shipments and reloading the products directly into a waiting outbound trailer. By utilizing this method, you now use your fulfillment provider as a sorting center. The method will help reduce costs by taking out storage and additional labor costs. However, it will require additional shipping plans due to tracking individual orders from the start.

Economic Order Quantity (EOQ)

The economic order quantity method helps your business calculate the optimal order quantity for your business. By using this formula, you have the opportunity to reduce storage and order costs. How? Ordering the correct quantity of product for your business allows you to stray away from overordering. Thus, you eliminate the amount of products that are being shipped from your supplier and reduces the amount of items that gain dust on your warehouse’s shelves.

Safety Stock Inventory

Safety stock inventory is the opposite of just-in-time management. For some businesses, you need to order more products from your suppliers than what is actually in demand. You might ask yourself, “why?” It’s simple. For some businesses, they rely on seasonal purchases. For example, you might not buy a snowboard during the summer or a paddleboard during the winter. As the season nears, businesses will order safety stock to ensure that they are covered and ready for the rush of seasonal buyers. Similarly, you might see businesses do this in preparation for sales holidays like Black Friday and Cyber Monday.

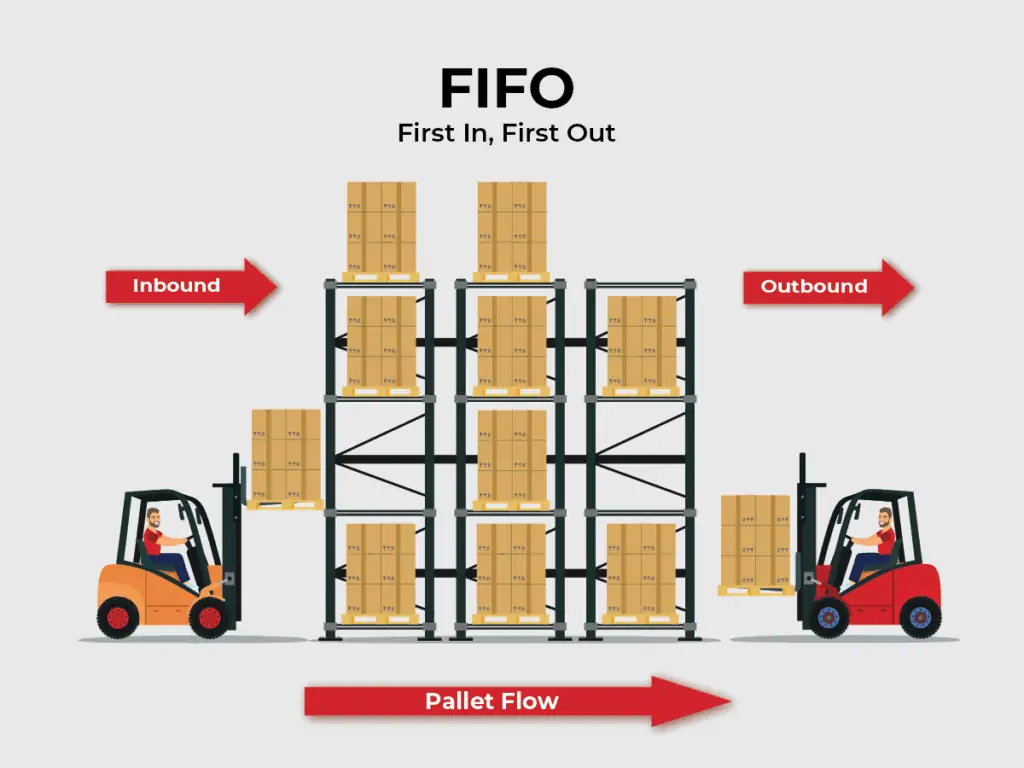

First in, First out (FIFO) and Last in, First out (LIFO)

FIFO and LIFO are common inventory management practices. FIFO is best used when perishables are involved to ensure that items are pushed out before its expiration. How? Think about your local supermarket or convenience store. When you go on stock days, you might see employees place new perishable items like orange juice, produce, and milk to the back. By doing this, you allow for your older products to stay at the front to convince customers to pick those items first.

The opposite of this is LIFO. For LIFO, you are forcing your newest items out first. A great example of this is car dealerships. Dealerships will receive the newest models and try to push those out first before the cars that might have been sitting at the dealership the longest.

The Importance Of Inventory Balancing

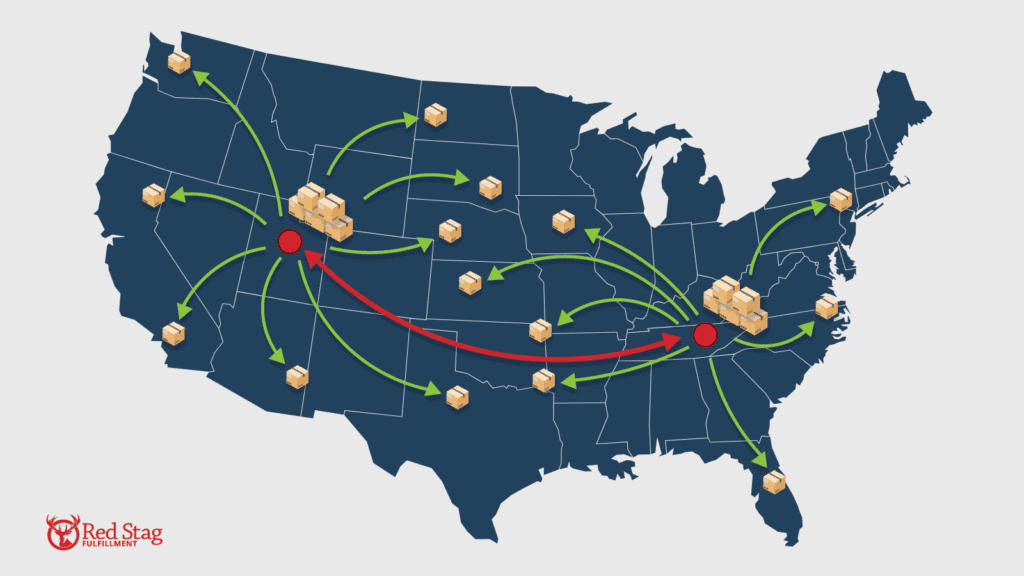

Inventory balancing is a step that some businesses overlook. To properly balance an inventory, an eCommerce business moves stock to another location to meet buying demand. This process can clear up space and allow businesses to take an accurate count on slow-moving inventory. In turn, it can help an eCommerce business budget correctly for the future.

Available Storage Space

It’s no secret that every business dreams of having more space in the warehouse. You can have ample room to fill shelves with best sellers, hot products, or overstock by properly balancing your inventory. How? Inventory management. By working with an inventory management system, businesses have the ability to properly track trends and customer buying habits based on demographic attributes. From there, inventory can be moved to the locations that make the most sense based on demand. Balancing your inventory among your warehouse locations can free up space for more products.

Reduced Shipping Costs

By balancing inventory, your business is able to reach customers easier and faster. Allocating products to the appropriate places based on demand can allow you to easily reach your customers. For example, let’s imagine your business experiences an increase in buying interest from the West Coast, but you have most of your products on the East Coast. By taking a portion of your best-selling products and shipping them to a West Coast facility, you will be able to increase delivery speeds and decrease shipping costs.

Reprioritize Under-Selling Products

Freeing up space throughout your warehouse can give you a new perspective on what products you have available. Imagine all the times you go through your closet and uncover clothing that you forgot you had. It can be similar for businesses that have crowded their shelves with their best sellers. Pushing your best sellers to better locations can bring those under-selling products forward.

How is this a benefit? Businesses can use under-selling products to their advantage. By uncovering those products, eCommerce businesses can create additional marketing campaigns to increase sales. You can create promotions, build kits, or even offer giveaways to push your products.

How can Red Stag Fulfillment help with inventory management?

It can be difficult to figure out which inventory management method might be best for your eCommerce business. With Red Stag Fulfillment, you will be paired with fulfillment experts who can work with you to discuss the best inventory management methods, give you access to inventory management systems, and help reduce storage costs.

Here at Red Stag Fulfillment, we understand that fulfillment can be complicated. That’s why we want to take the burden off your shoulders. If you’re looking for a 3PL provider, why not contact us? Reach out today to see how you can experience a stress-free eCommerce fulfillment.

Want to learn more about inventory management? Here are a few articles: