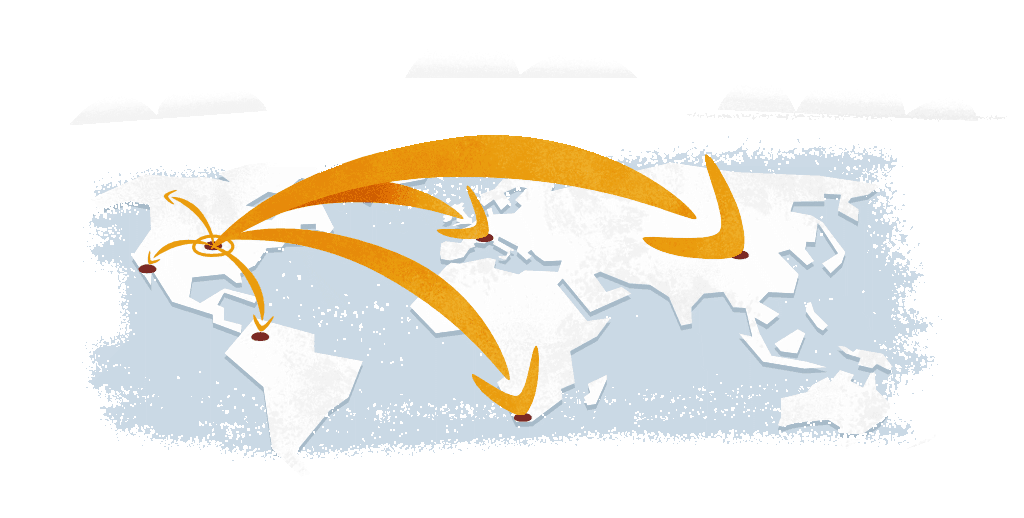

Your eCommerce fulfillment plan probably covers the most significant pain points for your business. It keeps your inventory management lean but uses demand forecasting to ensure that your most popular products are rarely backordered. You use national fulfillment center locations to get orders to your North American customers fast and reduce shipping costs. But, if you’re like many U.S.-based eCommerce companies, you may not yet have a global order fulfillment strategy.

ECommerce breaks down geographic barriers. Increasingly, sales cross borders. Even small and mid-sized online stores need global order fulfillment strategies to deal with international orders.

Every eCommerce business is an international business

If you don’t offer international shipping, you could be missing out on major markets for your products. According to Shopify, the U.S. continues to be the top eCommerce exporter. Consumers from around the world want U.S. goods. Statista predicts that cross-border eCommerce will account for 22% of online sales by 2022, up from 15% in 2015.

Here are three things you can do to facilitate international eCommerce sales:

- Accept payment options that work for international customers.

- Develop a global order fulfillment strategy that works for your business and your customers.

- Provide fast international shipping that isn’t cost-prohibitive.

If you don’t have a plan for international eCommerce, you could be missing out on a big market for your products. Fortunately, serving global consumers is becoming easier all the time.

Global order fulfillment options for U.S. companies

U.S. eCommerce companies that want to ship orders internationally can ship international orders from their U.S.-based warehouses or work with global fulfillment centers. The best alternative for your business depends, in part, on the volume of your international sales and the distribution of your international customers.

For example, if 20% of your orders go to the EU, shipping your EU orders from a warehouse inside the Schengen Area might make sense. Your orders will reach your EU customers faster, you’ll save on international shipping, and individual orders won’t get held up at customs.

On the other hand, only 10% of your sales might be international. Additionally, suppose your international customers are scattered among Canada, Australia, the EU, and South Korea. In that case, you might find it more cost-effective to run your global order fulfillment from one or more of your U.S. fulfillment centers.

U.S. companies aren’t the only eCommerce businesses that need global order fulfillment services. International companies that want to sell into the U.S. sometimes need a North American partner for global order fulfillment. Establishing an eCommerce hub in the U.S. gives companies better access to a big market for eCommerce products.

Careful analysis of your operating expenses, customer feedback, and sales trends will help you determine the tipping point where it makes sense to work with a global fulfillment partner.

Pros and cons of cross-border fulfillment

As you decide what route to take for your global order fulfillment, it’s essential to consider the pros and cons of the different approaches.

Global order fulfillment using U.S. fulfillment services

Pros of shipping your international orders from U.S. fulfillment centers:

- You have more control over your inventory. If you work with just one 3PL and can manage and view your stock through a single portal, you’ll have greater inventory visibility.

- You could end up with stranded stock. After you have paid to ship products overseas, it would be inefficient to send back items that didn’t sell, even if those products are popular in the U.S. You may have to sell leftover merchandise at a steep discount, especially as you get to know your international markets well enough to do accurate inventory planning.

- The flexibility you gain may offset some of the downsides. One of the benefits of outsourcing your fulfillment is that your costs are variable rather than fixed. You can reduce the amount of cubic footage you pay for during your slow season and expand when your sales pick up. The logistics of keeping a global fulfillment center stocked with your items may remove some of your flexibility.

Cons of cross-border shipping packages from a U.S. fulfillment center:

- You’ll have higher shipping costs. International shipping charges could discourage some global consumers. If you cover part of the cost, that cuts into your profits.

- It takes longer to deliver orders. Even if your U.S. fulfillment center is lightning-fast, international shipping will take longer than sending a package from a warehouse closer to the customer. You can use a faster service to cut down on delivery time, but that will probably lead to a higher shipping cost.

- More customs paperwork. International packages need customs paperwork, increasing the cost of global fulfillment.

Global fulfillment with international fulfillment services

There are several benefits when you use global fulfillment services. However, it’s essential to consider the downsides, too.

Pros of using a global order fulfillment warehouse:

- Your customers get their orders more quickly. Shorter delivery times can help you convert international shoppers into loyal customers for your brand.

- You can charge less for shipping. The per-item cost to send a freight shipment of products to an international fulfillment center is probably less than shipping each order overseas. You might even save enough to offer free shipping to your international customers.

- Easier returns. An easy-to-use return policy is essential in eCommerce. Cross-border returns are complicated and can be expensive. Your customers will appreciate the simplicity of an in-country location for returns.

Cons of global order fulfillment operations:

- You’ll need to understand and comply with local laws and regulations. Shipping from another country is not as simple as contracting with global fulfillment providers and shipping products to its warehouse. You may need business licenses, a bank account, a visa, and more before your orders can ship from another country.

- Stocking additional warehouses ties up capital. The more warehouses you use for global fulfillment, the more inventory you need to carry to keep each one stocked. Money that you could use for marketing or other operational expenses is sunk into inventory. It’s vital to understand whether your inventory turnover rates justify the extra inventory expense.

- You might have to revise your supply chain. Your U.S.-based 3PL is integrated into your supply chain. Adding a global fulfillment center requires adjusting your operations to supply more than one country. In addition, disruptions due to COVID-19 have made international supply links more fragile, so it’s critical to ensure that any changes won’t upend your supply chain.

How to find the best global fulfillment partner

Red Stag Fulfillment is a global order fulfillment partner to several international brands. We provide U.S. fulfillment services that help our clients take advantage of the lucrative North American market. And we also offer international shipping and fulfillment services.

At Red Stag Fulfillment, our number one goal is to help our clients’ eCommerce businesses grow and prosper. So, whether that means helping you find a global order fulfillment partner or providing your global fulfillment, we are here for you. Call us to find out how we can help.

More about global order fulfillment:

- Your Ultimate Guide to International ECommerce Expansion

- From Suez to Seattle, Global Bottlenecks Remain an Ongoing Threat to ECommerce Logistics

- How Will the Coronavirus Affect Your Global Supply Chain?