Dunnage is a common logistics term that’s slowly making its way to the ears of eCommerce businesses and regular consumers, but there’s still confusion around the term, what it includes, and its value to your business. Let’s take a quick minute to discuss dunnage, why it’s a vital part of eCommerce fulfillment, and why you’re likely to need it sooner rather than later.

What is dunnage?

Dunnage is the protective material used to cushion products and packages to protect them in transit and before use. It can be made from a wide variety of different materials for different uses. This includes:

- Plastic inserts inside a product’s own packaging

- Packing materials or filler you put around a product in a shipping box or poly bag, including environmentally friendly options like crinkle paper or corrugated paper and more water-protective materials such as bubble wrap

- Inflatable dunnage bags used to secure cargo

Whether your most recent purchase arrived in an Amazon box or by cargo ship or rail car, dunnage was involved in the process. Using dunnage options for your business can yield significant savings because the damage protection dunnage provides can save you from product loss during shipping. A top order fulfillment provider, like Red Stag Fulfillment, can help ensure that you have proper dunnage to safely ship even the most delicate products.

What is dunnage in trucking?

Trucking dunnage is any material that is used to protect and support cargo during transportation by a semi. Dunnage to protect freight during trucking can be made from wood, plastic, foam, or paper (see types of dunnage below). Loads that could shift during transport and get damaged, such as high-tech construction equipment or large containers of liquids, need the damage protection provided by dunnage.

Dunnage in other industries

The term “dunnage” can refer to anything that helps protect goods (and sometimes people) in a variety of settings. For example, restaurants use metal dunnage racks to store and transport food and other items. Even the non-slip rubber mats commonly found on the floors of commercial kitchens are a type of dunnage.

Dunnage materials can be used to protect equipment during storage as well as shipping. Materials used to stabilize boats in drydock for repairs are a type of dunnage. And the temporary supports used to prop up structures such as bridges or overpasses during construction also qualify as dunnage.

3 benefits of dunnage in fulfillment

By design, dunnage materials protect your business as much as your shipments. Here are three of the most significant ways that smart dunnage use will improve your operations.

Damage protection

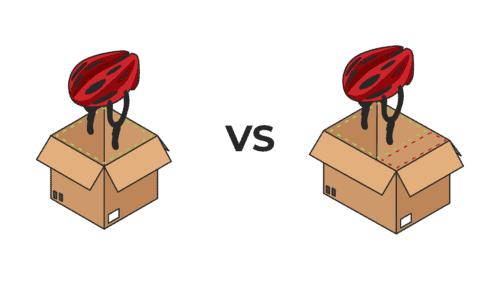

Dunnage is primarily used to protect the goods you send and receive as they move from factory to distribution center and from warehouses to customers. Your products may get damaged during loading onto trucks, stacking, sorting, and much more. The right dunnage options protect your goods against the most significant threats they face on the road.

Dunnage limits the damage to your products by offering shock absorption, increasing bulk around goods to absorb impact during collisions or from heavy items stacked on top. Dunnage protection can also limit the damage caused by environmental conditions such as moisture or heat. Using proper packing materials will keep your goods in place during transport in shipping containers, on pallets (themselves a type of dunnage), or via other distribution methods.

Protecting your profits

Dunnage limits breakage and can help you keep more of the revenue from each month’s sales. These packing materials are generally quite inexpensive, and the right packaging components give you security. When your items arrive safely to customers, they will be happier and more likely to order from you again. And, if merchandise arrives damaged, you’ve got to refund the cover or pay for the return and replacements, so dunnage is essential for high-value shipping.

You’ll also save by having fewer returns and refunds due to damage. If changing dunnage prevents just a few damaged and replaced items, that move can generate positive ROI in its first month. So, choosing and using significant dunnage to protect your products helps you keep more of the money you make by limiting unsalable merchandise and reducing after-sale costs.

Reducing labor costs

Lower labor costs are an additional benefit of using dunnage. Giving your team proper dunnage and guidance on what damage protection each product needs can speed up your packing process. This improvement will move more orders out the door each day, allowing your packing stations to be more efficient.

Common types of dunnage

You can utilize many different types of packaging materials as infill to protect goods during shipping. We’ve seen it all, from standard packaging components like bubble wrap to eco-friendly recycled materials such as wood chips and twine. There’s rarely a “wrong” choice, but many standard elements have specific instances where they perform best. Here are a few of the most common types of dunnage we use for our order fulfillment services.

1. Kraft paper

Kraft paper is large and flexible, supporting multiple infill methods. You can rip it as needed to wrap around products or bunch up in empty space. Crumpled, torn, or wrapped, kraft paper gives medium protection at an affordable rate. It is easy to acquire and can be recycled after receiving.

2. Air pillows

One of the biggest newcomers on the scene is the air pillow. These plastic pillows are inflated to give cushion while being relatively cheap and lightweight. That makes them a big draw for eCommerce because you aren’t adding bulk (and cost) to your shipments. Some options can be recycled — though most can’t — so if you’re paying extra for that feature, be sure to explain it to your customers.

3. Bubble wrap

You know it. You’ve used it. The ever-present bubble wrap is perfect for protecting delicate items and giving the kids something to do when you’re done unwrapping a present. It can be used repeatedly, which is good for the environment and your customers.

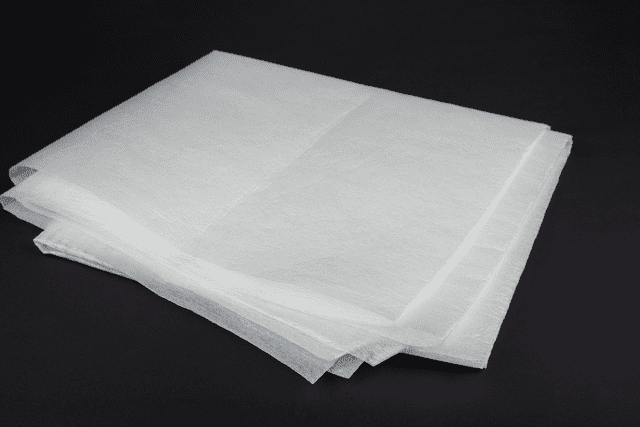

4. Foam wrap

A common alternative to bubble wrap is the foam version. Made especially for fragile products, foam wrap is a thin, light material that provides padding. You can buy it in sheets, and some specialty items will have custom sleeves of foam wrap. You might’ve seen these sleeves for wrapping items such as china and dishes. While it can be used repeatedly, it can’t be recycled.

5. Crinkle paper

Repurposed cardboard boxes, called crinkle paper, can be shredded and used to protect fragile items. You can do the recycling yourself if you have a machine that cuts them into accordion-like sheets or shredded strands of cardboard. The sheets are flexible enough to wrap around fragile items and provide strong protection, so they’re a common choice for bottles and other glassware. You and your customers will also enjoy that they are eco-friendly and can be further recycled.

6. Box inserts

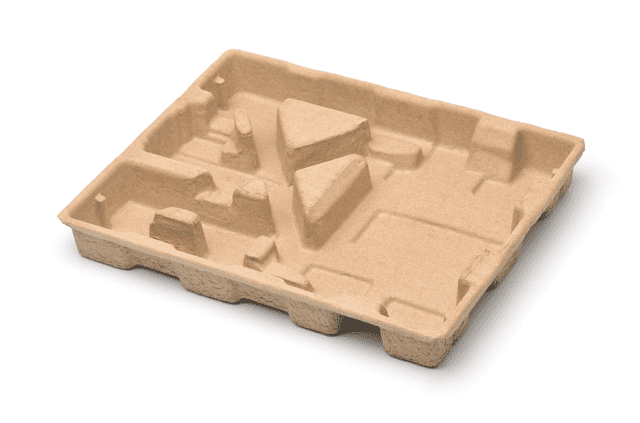

If you’re shipping heavy or sharp products, especially in industrial and B2B settings, you might want to consider rigid plastic or solid plastic dunnage. These items are often molded to protect your product, so you must have consistent dimensions for products and the boxes or containers used to ship them. These units are more expensive, and you may have to meet specific requirements for using some in freight, but they can protect large and bulky equipment better than almost anything else. You can also use molded cardboard as an eco-friendly option. Molded foam is commonly used dunnage that is set inside a product’s own packaging.

7. Packing peanuts

Many cities have banned Styrofoam packing peanuts because they’re not recyclable. Consumers don’t like them either, for many of the same reasons. But packing peanuts are an eco-friendly, versatile dunnage material that you can pack around odd-sized goods. And fortunately, peanuts made from cornstarch can be shipped everywhere.

8. Dunnage bags

Large, inflatable bags used to keep cargo from shifting or colliding with other cargo during shipping are called dunnage bags. They are made from durable, puncture-resistant materials such as polypropylene or nylon. A dunnage provider fills them with air using a compressor or hand pump. Dunnage bags have the advantage of flexible sizing to fit into empty spaces in shipping containers between pallets or large items such as heavy machinery. The bags, or more traditional shipping dunnage made from wood supports, are essential for shipping high-value products such as medical equipment.

Get help sourcing custom dunnage

Working with a 3PL like Red Stag Fulfillment gives you access to a broad range of dunnage materials. To help our customers protect their shipments, we stock many of the types of dunnage mentioned above, and we work with each client to determine the optimal packing solution for their products.

If you need damage protection to safely ship fragile or high-value goods, we can help you find custom dunnage solutions. We can work with you to source custom inserts and boxes, uniquely sized padded mailers, eco-friendly tape, plus branded options for tape, boxes, and more. All of these build your brand while delivering your products safely to your customers.

There are plenty of non-dunnage ways to improve the look and feel of what you send, from custom receipts and flyers to stickers, tissue paper, and pre-printed offers or discounts. Whatever you prefer, we’ll help you create and ensure it’s in every order that lands on a customer’s doorstep.

Talk to Red Stag about dunnage or any other shipping and fulfillment questions.

More about shipping options for heavy, fragile, or high-value products: