Online shoppers have come to expect the instant gratification of next-day delivery. Consumers’ willingness to wait to receive their orders has dwindled significantly in the past half-decade. If your eCommerce fulfillment process takes too long, you’ll lose sales. One of the best ways to shorten your delivery window is to reduce lead time with help from a 3PL.

A deeper understanding of what lead time is, its components, and how reducing it can help your business grow. In this guide, you’ll find everything you need to know about lead time and how to use it to optimize your order fulfillment.

What is lead time?

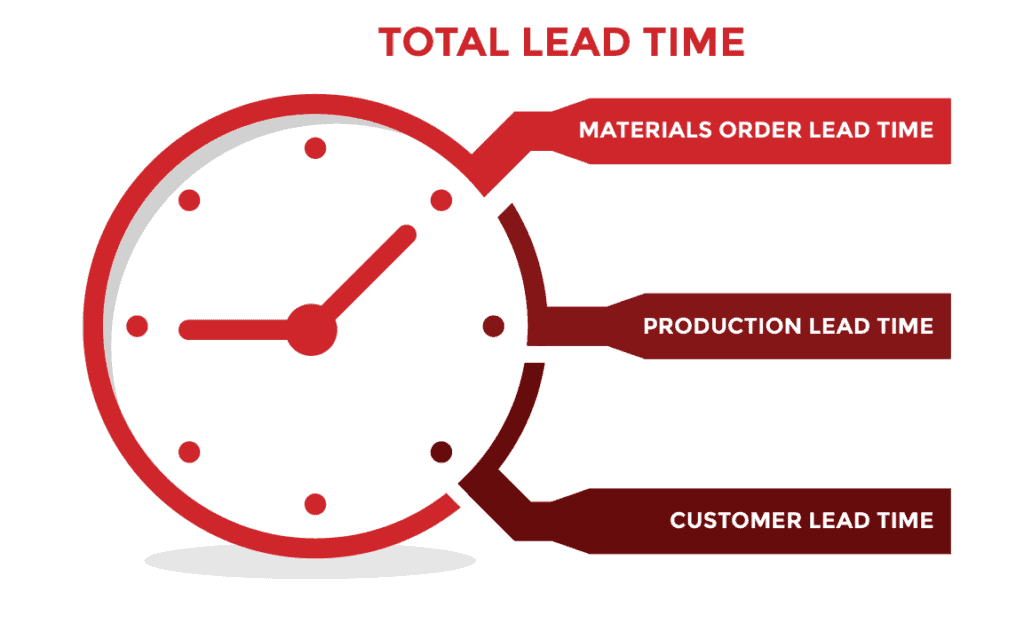

Lead time is the length of time it takes from when a purchase order is generated to when an item is delivered. Each element of your supply chain has its own lead time.

- The time it takes for an order of raw materials to be delivered to the factory is the material lead time.

- The time from when your factory gets an order to production and delivery of finished goods is production lead time.

- Customer lead time is the time from when someone places an order in your eCommerce store to when the customer receives their order.

All these elements together make up the total lead time for producing and delivering products. Customer lead time is the most important marker of satisfaction for eCommerce companies. Consumers expect fast delivery, so shortening the time from customer order to delivery can increase your sales.

The time it takes to complete each element of your supply chain affects your inventory planning and cash flow. Suppose you want to facilitate shorter customer lead times while following lean business management principles and using just-in-time inventory management. In that case, you’ll need to shorten your material and factory lead times.

The relative lead times of production versus customer orders are crucial in determining how much stock you need to keep on hand. You want to set reorder levels that protect you from stockouts, backorders, and lost sales.

How is lead time different from cycle time and takt time?

Lead time is related to but different from cycle time and takt time.

Cycle time refers to the amount of time it takes to manufacture a product from beginning to end. To calculate the cycle time, take your net production time and divide that by the number of product units you can make during a production cycle.

Takt time is the time that it takes a person or group of people to complete the production process to satisfy customer demand.

To satisfy customer demand and shorten total lead time, you may have to make some adjustments to your workflow so that your cycle time better fits your ideal takt time.

In manufacturing, factors like the availability of materials and shipping delays can affect your materials and production lead time. Even if you have a short cycle time (and one that meets takt time), these factors can prolong the time it takes to get orders to customers.

Why is a shorter lead time important?

A reduced lead time comes with an array of benefits. Here are five of the most important ones:

- You can hold less inventory in your overall supply chain at different stages. When you reduce material and production lead times, you can optimize your inventory management.

- A shorter total lead time also allows you more flexibility when there are sudden shifts in the market.

- You could also end up with more cash on hand for your business. You can use the extra money to buy stock or extend your marketing reach. The shorter the total lead time, the longer you have to use your cash on hand. This also allows you to replenish inventory faster and avoid losing sales and customers.

- A shorter customer order-to-delivery time gives you a competitive edge with online consumers and can increase your sales. Reducing your total lead time can also help you succeed in eCommerce.

- A reduced lead time will help you meet your production goals and have seasonal items ready for consumer demand.

Unfortunately, no matter how high-quality your product is, if it takes too long to reach your customers, they won’t be satisfied with your overall service. Longer lead times can also lead to inefficient resource use, higher expedition costs, and excessive inventories, all of which could drain your company’s funds. Reducing total lead time, especitally order fulfillment time, is critical to your eCommerce success.

Components of lead time

Your lead time consists of several components or stages. Each stage is an integral part of the process.

- Materials order time: The factory orders the raw materials it needs to produce your order.

- Production time: The manufacturer produces the goods in the order and delivers them to the fulfillment warehouse.

- Customer lead time: A customer places an order on your eCommerce store; your fulfillment center packs and ships the order; UPS, FedEx, or USPS delivers the order to your customer.

Calculating your total lead time is essential in managing your inventory. As lead time affects your overall operation and customer satisfaction, you must know how to calculate your current lead time so you know what you are working with and can plan how you can improve it.

Calculating lead time is relatively easy. All you need to do is add the time spent on each stage. Here’s a formula:

Total Lead Time = Materials Order Time + Production Time + Customer Lead Time

Other factors that affect lead time

Despite significant improvements in supply chains in the past few years, several factors can contribute to longer lead times.

Stockouts

Stockouts can affect any element of your supply chain. If your factory can’t get the raw materials it needs, it won’t be able to produce your order. This is particularly true if the factory operates on a just-in-time model and doesn’t hold inventory ready to ship on demand. Miscalculating your lead time can result in stockouts in your online shop — something you’ll want to avoid if at all possible.

Lead time variability

It can be challenging to predict how much time it will take your items to be delivered because lead time varies from one supplier to another. Production delays are inevitable because of this. One thing you can do to avoid this problem is consolidating suppliers so that you’ll get all that you need for your production at the same time.

Shipping delays

Yet another factor that you can’t control is shipping issues. From human error to natural disasters, there are a hundred things that could cause shipping delays. While it’s impossible to eliminate shipping-related problems, you can reduce them by choosing a 3PL like Red Stag Fulfillment that is proactive about finding workarounds for shipping issues.

Unnecessary internal processes

It takes longer to complete every order if you need to build every single component of your product. You might want to consider outsourcing pre-assembly to minimize production time. When you can reduce time spent on production, you will also reduce lead time.

Inefficient control or inventory management

Mismanagement of inventory can be disastrous. Failure to keep track of your stock means you won’t know when you will need to order new products to send to consumers or whether you still have parts available for manufacturing. Efficient inventory control will improve production and lead time.

How to reduce lead time

While it is true that there are uncontrollable factors that affect your total lead time, you can take several steps to minimize it.

Create contracts with all your suppliers that include defined timeframes

Does your contract include set delivery timelines? If not, it’s time to consider creating a lead time contract. Some suppliers promise impressive turnaround windows, but can’t deliver. The best way to hold them to their word is by asking them if you can have a legal agreement that reflects the agreed-upon delivery time for your orders.

You might want to include these lead time elements in your supplier contracts:

- Delivery times for specific orders

- Penalty for delayed shipments

- Liability for damaged or incorrect goods

- Advance notice of price changes or stock shortages

Reduce or eliminate non-value-adding tasks

You should perform value stream mapping to determine any activities that do not add value or that prolong lead times. You can list these activities and figure out which can be eliminated and only keep those that affect your product quality in a big way.

Source from local suppliers

When you source your products overseas, the lead time may be significantly longer. In addition, overseas shipments run a greater risk of transport disruptions. Include local producers in your roster of suppliers to protect your supply chain.

International suppliers may offer you lower prices. However, if you add the shipping costs and the amount of inventory you need to hold because of the long production lead time, you may find that a local supplier is a better partner for your eCommerce business.

Place smaller orders more frequently

If placing larger orders translates to a longer lead time, you might want to consider ordering in smaller quantities more frequently. Smaller orders could shorten your order processing time.

Consider changing shipping methods

If shipping makes up a big chunk of your production time, it may be time for you to consider a different shipping method. That may mean a higher cost than the preferred shipping methods of your suppliers, but it’s worth checking out.

Offer incentives to suppliers

As mentioned above, you should include a clause about delivery timelines in your contract. You should also consider offering incentives to your suppliers who can fulfill orders on time or in advance. This way, your suppliers will be more likely to stick to the lead times they promised.

Automate your inventory management

If you are still manually entering data and purchase orders, consider shifting to an automated system. There are many excellent inventory management apps and software to automate processes like stock-taking, supply chain management, and more. Apps can save you time and improve the accuracy of your inventory management.

Share sales data with your suppliers

Work collaboratively with your suppliers to reduce your lead time. If your supplier has access to your sales and inventory data, it can anticipate the incoming order and even prepare in advance to ship out as soon as you send your purchase order. Visibility up and down your supply chain will help all the elements work better together, reducing your lead time.

Find out how your 3PL can help you reduce lead time

Lead time is a crucial metric for every eCommerce business. It affects productivity, operational workflow, customer satisfaction, and, ultimately, sales. Reducing total lead time is essential for agile business management.

A logistics company like Red Stag Fulfillment can help you reduce your customer lead time with fast, accurate fulfillment. We also help our clients improve inventory management and find efficient freight forwarding methods to minimize transport time and costs. In response to this challenging year, we have even developed a variable pricing model to help our clients thrive. Your fulfillment company can be your supply chain experts, helping you improve every aspect of your eCommerce operations.