If there’s one hard truth that all ecommerce owners know, it’s that some inventory shrinkage is unavoidable:

A box drops during unloading.

A supplier sends the wrong quantity.

A product expires before you sell it.

And you know that shrinkage costs you — maybe more than you realize. Many warehouses, logistics partners, and fulfillment providers even build what they consider to be an “acceptable” shrinkage rate into their service agreements.

At Red Stag Fulfillment, we think the acceptable warehouse shrinkage rate for ecommerce fulfillment should be zero, and that’s why we include it in our fulfillment guarantees. We know that any shrinkage hurts your company — we’ve been there — and we’re determined to treat your products like our own.

If you’re focused on growing and scaling your business, ask yourself if inventory loss is holding you back.

Average warehouse shrinkage rates in the fulfillment industry

It’s hard to pin down an average warehouse shrinkage number because no fulfillment center wants to admit how much of its clients’ products it loses. A few years ago, the reported average rate of inventory loss was 4%, and that shrank to 2% as warehouse processes improved.

But, keep in mind, that these averages are based on reported data and surveys. In fulfillment contracts, the shrinkage allowance can range from zero (at 3PLs like Red Stag Fulfillment) to as high as 10%. That’s a pretty large window.

Red Stag Fulfillment had a 99.999% inventory accuracy score in the first 3 months of 2024, so our shrinkage rate was 0.001%. And, even on rare occasions when an item was missing or damaged, our clients never lost because we pay the replacement cost for any missing inventory in our warehouses.

PRO TIP: If your inventory shrinkage is more than 1.5%, you could do better. If it’s less than 0.01%, your 3PL is among the best in the industry.

Understanding the cost of inventory shrinkage

An acceptable warehouse shrinkage rate of 1.5% or 2% might not sound like much, but the costs can add up. And, if 2% is the average, you might be losing even more. Running the numbers is critical because shrinkage can be a silent killer of ecommerce success.

A calculation of what it takes to replace the profit you lose to shrinkage highlights the damage that inventory loss can do to your business.

For example, suppose a Widget Company has a 10% profit margin on a SKU that retails for $10. If the company lost 50 widgets to shrinkage, it would have to sell an additional 500 units before the $1 profit per unit covers the $500 cost of lost inventory.

If the Widget Company had partnered with Red Stag Fulfillment, RSF would have reimbursed the company for its costs. But, if the widgets had been in a Red Stag warehouse, with Red Stag’s inventory accuracy rate, out of 1,000 widgets the company would have lost no more than one unit, and more likely none at all.

So, the real question is, “What is inventory loss costing your business?”

Impacts of shrinkage and inventory accuracy on your supply chain

Of course, the obvious impact shrinkage has on your business is the loss in profits, but that’s not the only effect. Units on your books but not physically on the shelf introduce errors that can get amplified in your order cycle and be hard to correct.

For example, safety stock you think you have in place could end up being inaccurate and you could oversell products you thought were in stock. That could lead to backorders and open the door for your competitors to take business from you.

In the case of the Widget Company, if those 50 lost units remained on its books, that could throw off inventory management and have ripple effects up its supply chain.

That’s why Red Stag Fulfillment’s inventory accuracy is critical to our clients’ success. When you work with RSF, you can trust the inventory on your books and make better inventory management decisions.

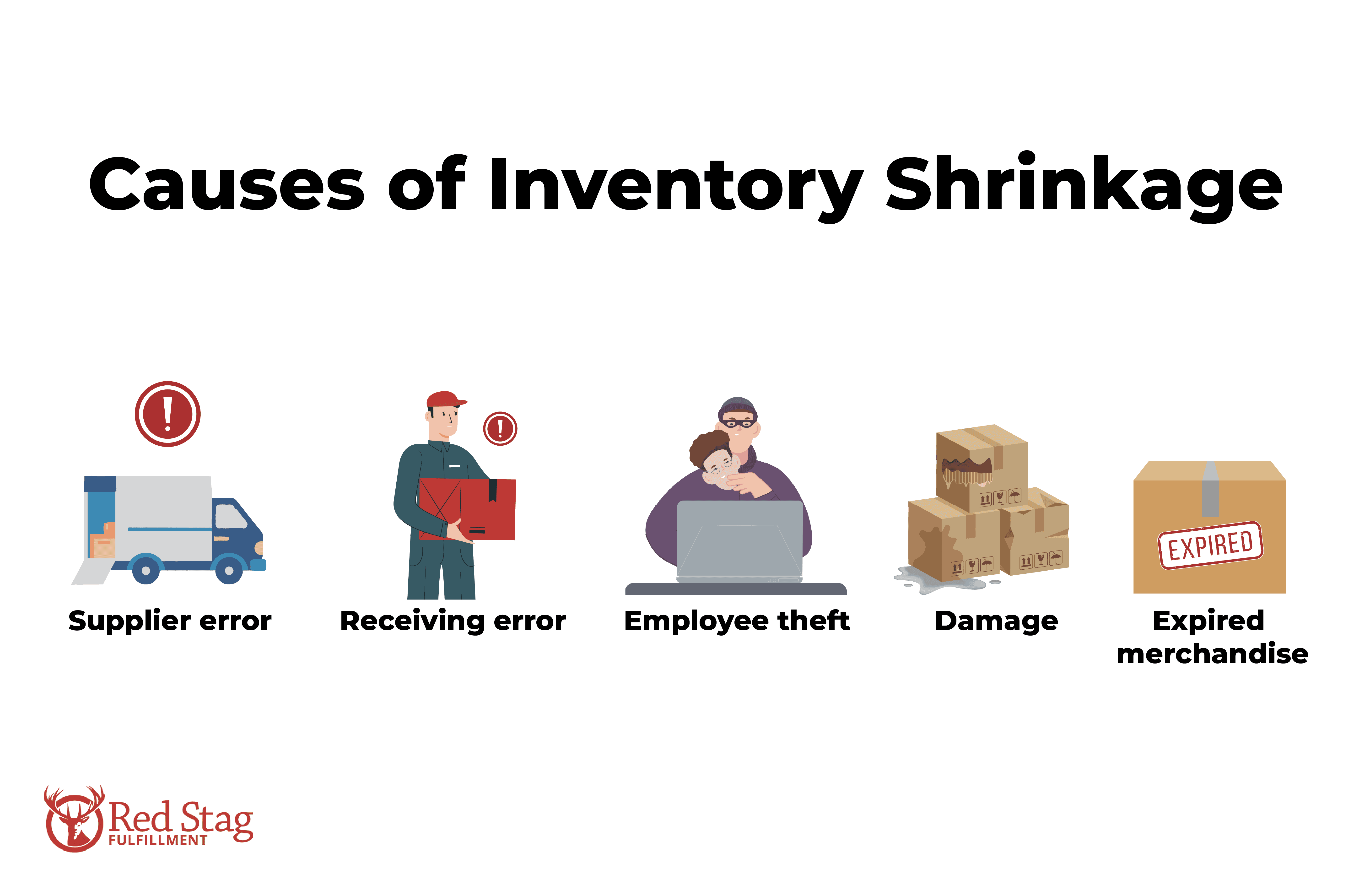

Causes of inventory shrinkage

Because Red Stag Fulfillment guarantees zero shrinkage, we have created warehouse systems to prevent loss. Of course, not all inventory loss happens in the warehouse, but our checks often uncover errors from other supply chain elements, so those errors don’t get into your inventory management system. Here are some of the most common causes of shrinkage and how Red Stag solves them.

Supplier error

The bill of lading or ASN for an inbound shipment can introduce inventory errors when it doesn’t match what’s on the pallets.

At Red Stag Fulfillment, our inbound team checks every shipment thoroughly. That ensures the units we log into inventory match the physical products we receive, which is critical because our acceptable warehouse shrinkage rate is zero.

Receiving error

Inventory problems often start with receiving. For example, if your 3PL doesn’t track an inbound shipment carefully enough, it could lose some or all of your stock in the warehouse.

That happened to Red Stag Fulfillment client Homestead Brands at the company’s prior fulfillment provider. The owner had to physically go to the 3PL and search the warehouse for their merchandise because the fulfillment center had misplaced the shipment (and the company’s products are not small).

At Red Stag Fulfillment, we guarantee that we’ll move your inbound shipments from dock to stock within two business days. You don’t have to worry about pallets neglected on the receiving dock, left outside in the elements, or lost in an uncharted corner of the warehouse.

Employee theft

Employee theft accounts for nearly half of all inventory shrinkage in ecommerce. Warehouse workers may be poorly paid and overworked, and they may feel that they aren’t likely to get caught.

At Red Stag Fulfillment, we start by treating our warehouse associates with respect and dignity. We constantly strive to improve worker experience, and we hire people who embrace the entrepreneurial spirit of Red Stag and take pride in our work. And we back that up with comprehensive security. We have full camera coverage of our warehouse spaces 24/7.

If anything goes wrong in the pick and pack process, including inventory shrinkage, we review the footage, identify the issue, and take steps to correct it.

Damage

Products can get damaged in transport or while being handled in the warehouse. Dents, scratches, and damaged packaging can turn items into distressed merchandise or make them unsalable.

Part of Red Stag Fulfillment’s receiving process is examining every box for damage. If a product arrives damaged from the factory, we don’t enter it into inventory, and we send you a photo. You can then submit a claim for the defect with your supplier.

ALERT: Improper handling is a common cause of damage in the warehouse, especially with large, bulky products. In a warehouse that specializes in handling merchandise under 10 pounds, you risk a 60-pound package getting scuffed, dropped, or banged up by staff who aren’t used to moving oversized merchandise. On the flip side, small or delicate products could be dropped, crushed, or lost in a warehouse designed to store and ship larger goods.

Red Stag Fulfillment supports products of all shapes and sizes and weights in our facilities today. We got our start, and remain experts in, heavy, bulky, fragile, and high-value ecommerce products. So, we know how to build our warehouses and teams to store and move large items safely with care. That foundation makes it easy for us to safeguard any product you bring us.

Expired merchandise

If you stock SKUs that expire, such as food products or supplements, you could lose inventory if you have outdated products on the shelves that can’t be sold. Products that go out of style, such as clothing, can become unsalable once the season passes.

FIFO fulfillment is a best practice for items with expiration dates. Red Stag Fulfillment works with each client to set up SOPs that ensure that we process your orders to maximize your inventory.

Acceptable warehouse shrinkage should be zero

Even if you manage your fulfillment in-house, shrinkage can be a problem. Your employees could mishandle inventory, things might fall off shelves, and your stock counts could vary from your recorded inventory. At Red Stag Fulfillment, we believe it’s our job to do better. As fulfillment professionals, we strive to provide pick and pack services that are as close to perfection as possible. That’s why we set our acceptable warehouse shrinkage rate at zero.

We have had clients who experienced significant savings after moving their fulfillment to RSF solely because of reduced shrinkage.

If inventory loss is an issue for your company, perhaps it’s time to experience the Red Stag Fulfillment difference. Get your customized quote today.